Quick Installation Guide

Rosemount 8712 / 8700 Series

Flange Bolts

Wafer sensors require threaded studs. See Figure 7 for torque sequence. Always check for leaks at the flanges after tightening the flange bolts. All sensors require a second torquing 24 hours after initial flange bolt tightening.

Table 5. Rosemount 8711 Torque Specifications |

|

| |

|

|

|

|

Size Code | Line Size |

|

|

15F | 0.15 inch (4 mm) | 5 | 7 |

30F | 0.30 inch (8 mm) | 5 | 7 |

005 | 0.5 inch (15 mm) | 5 | 7 |

010 | 1 inch (25 mm) | 10 | 14 |

015 | 1.5 inch (40 mm) | 15 | 20 |

020 | 2 inch (50 mm) | 25 | 34 |

030 | 3 inch (80 mm) | 40 | 54 |

040 | 4 inch (100 mm) | 30 | 41 |

060 | 6 inch (150 mm) | 50 | 68 |

080 | 8 inch (200 mm) | 70 | 95 |

Sanitary Sensors

Gaskets

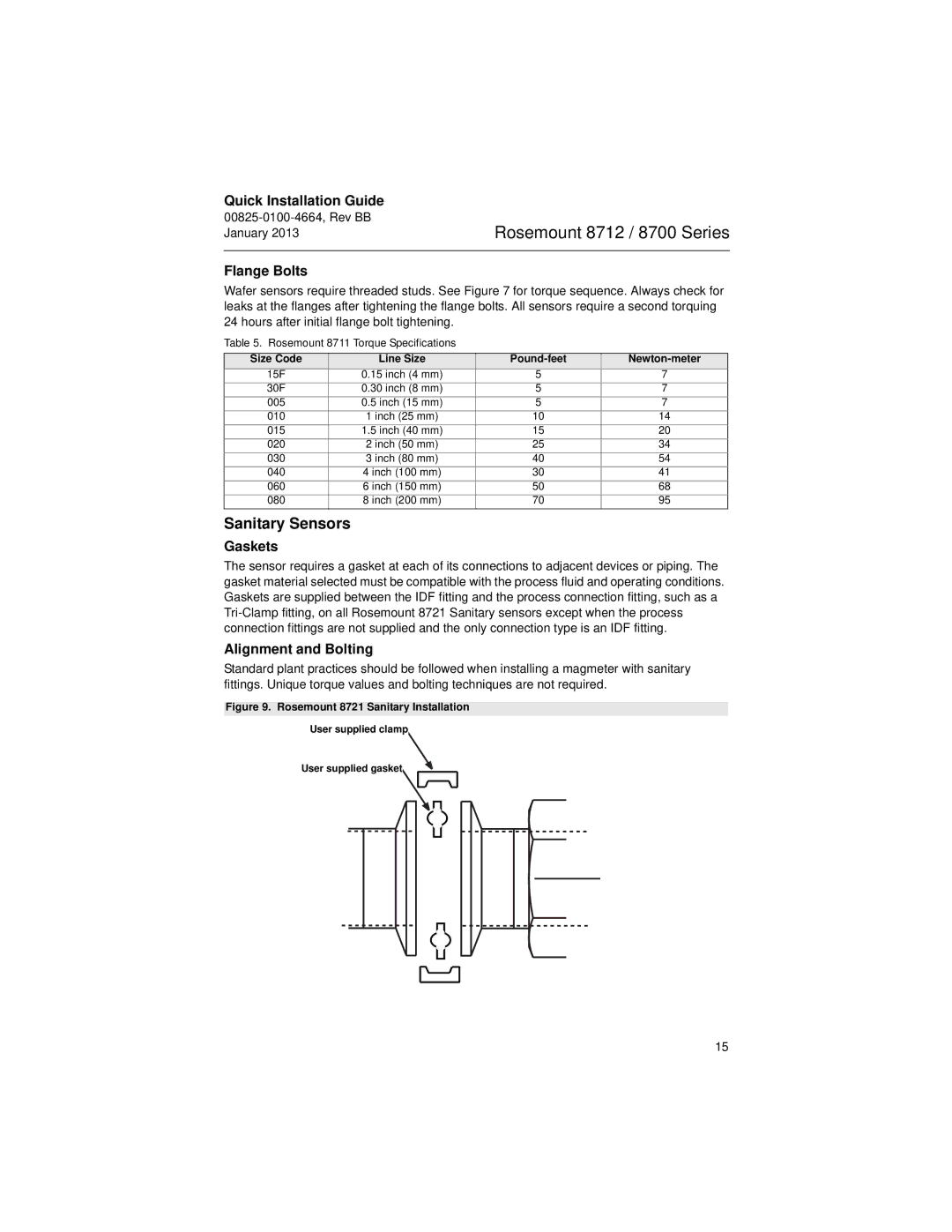

The sensor requires a gasket at each of its connections to adjacent devices or piping. The gasket material selected must be compatible with the process fluid and operating conditions. Gaskets are supplied between the IDF fitting and the process connection fitting, such as a

Alignment and Bolting

Standard plant practices should be followed when installing a magmeter with sanitary fittings. Unique torque values and bolting techniques are not required.

Figure 9. Rosemount 8721 Sanitary Installation

User supplied clamp

User supplied gasket

15