M2000 specifications

The Frymaster M2000 is a state-of-the-art fry cooking solution designed to meet the demands of high-volume commercial kitchens. Known for its efficiency and advanced technology, the M2000 sets a new standard in the frying equipment industry.At the heart of the Frymaster M2000's appeal is its innovative frying technology. This unit employs a filter management system that helps maintain the quality of the oil over time. The built-in filtration allows users to filter used oil while they continue cooking, significantly extending the life of the oil and ensuring that food is fried to perfection. This not only enhances the flavor of the fried products but also contributes to cost savings in oil usage.

The M2000 is equipped with a powerful heating system that guarantees quick recovery times. This feature is crucial in high-demand environments, as it ensures that cooking times are minimized without sacrificing food quality. The fryer's high BTU ratings allow for rapid heating, which is vital for busy restaurants, bars, and other food service establishments.

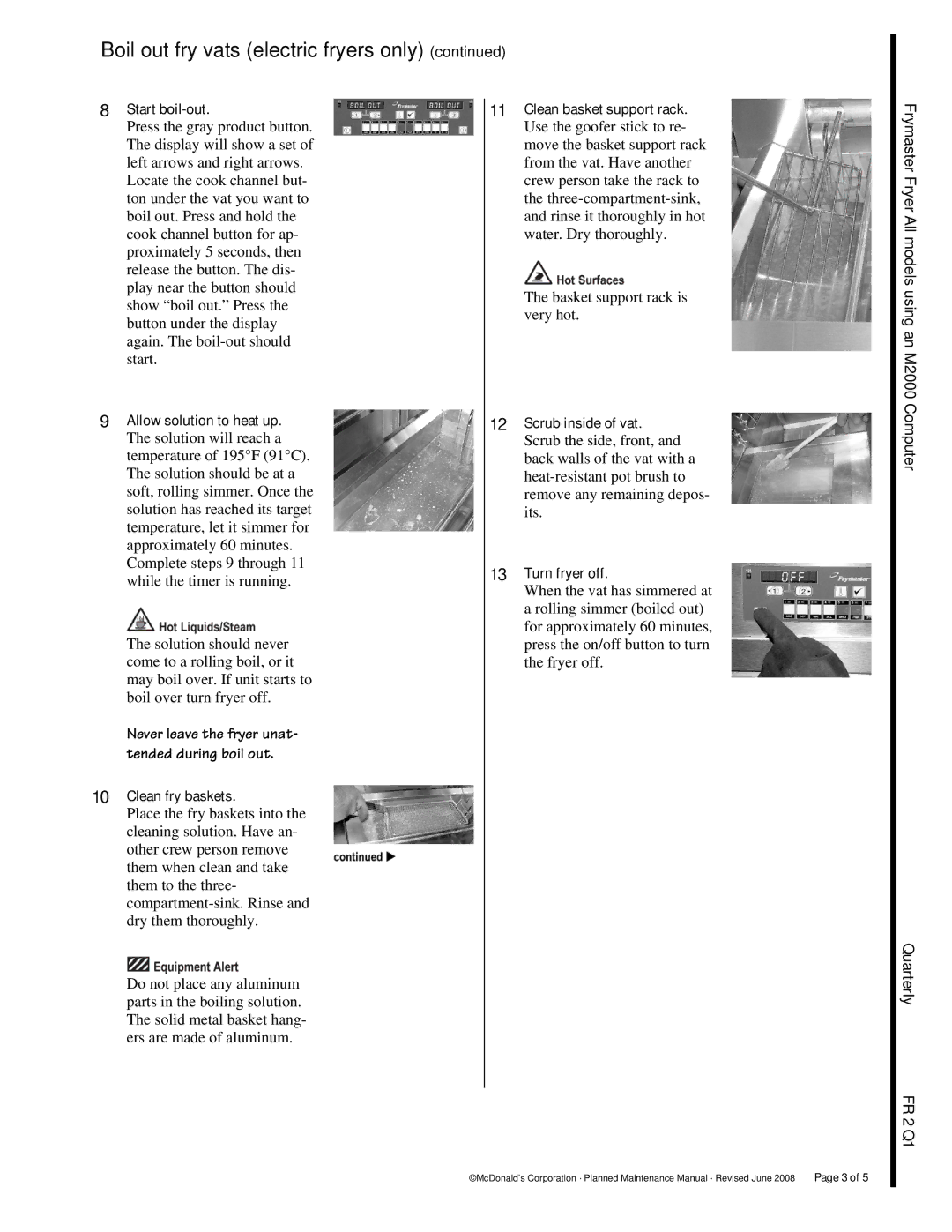

Another notable characteristic of the Frymaster M2000 is its user-friendly digital control system. The control interface allows operators to easily set and monitor frying temperatures, cooking times, and oil filtration cycles. This advanced control system also comes with built-in safety features that alert users to any irregularities, thereby ensuring safe and efficient operation.

The construction of the M2000 is robust, featuring a stainless steel body that provides durability and ease of cleaning. Its compact design maximizes kitchen space without compromising its frying capabilities, making it an ideal choice for establishments with space constraints.

Energy efficiency is another key feature of the Frymaster M2000. The fryer is designed to consume less energy while providing superior frying performance, reducing overall operational costs and minimizing the environmental footprint of the kitchen.

In summary, the Frymaster M2000 stands out for its advanced oil filtration system, powerful heating capabilities, user-friendly controls, durable construction, and energy efficiency. It is a reliable and innovative solution for any commercial kitchen looking to enhance its frying operations.