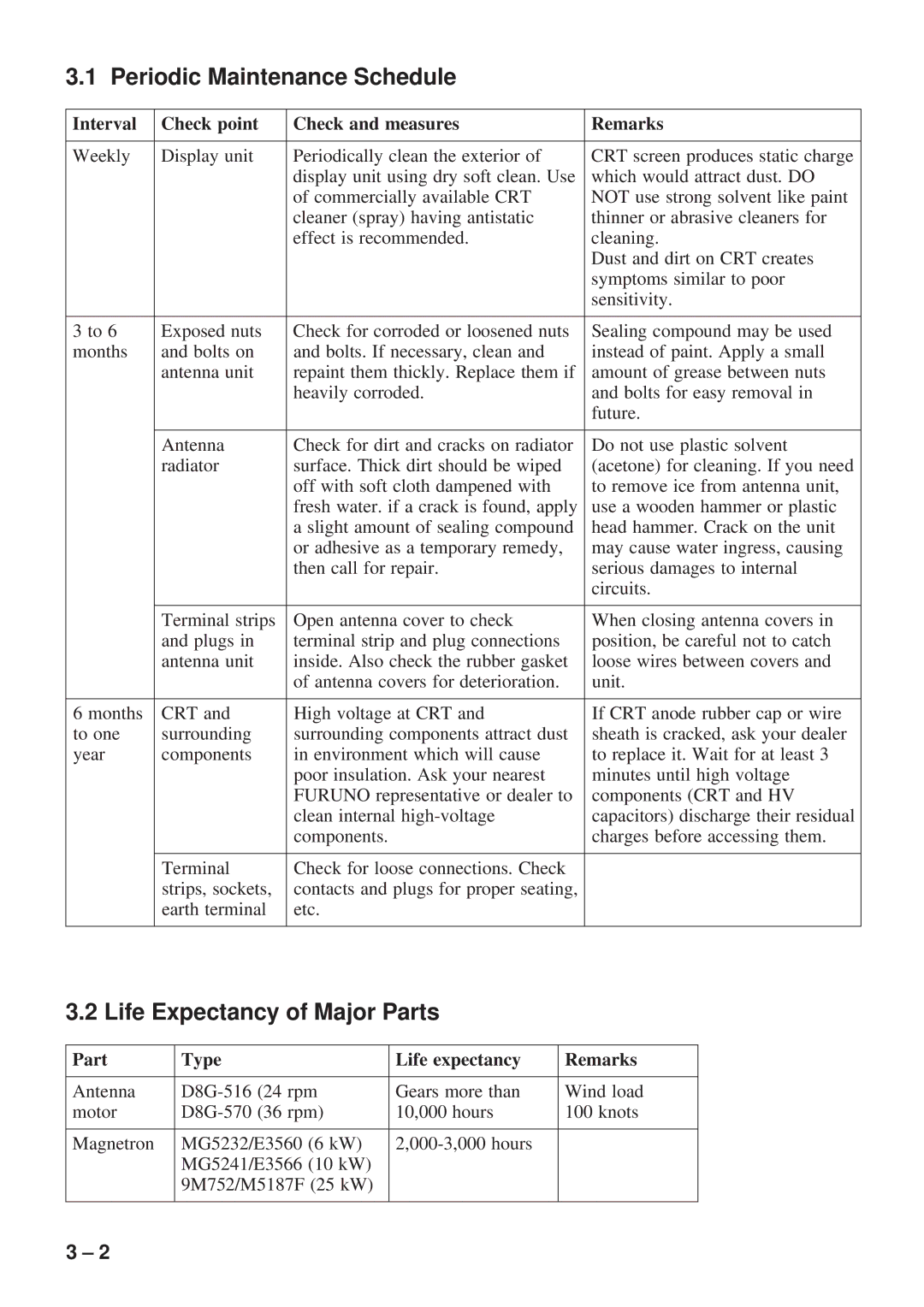

3.1 Periodic Maintenance Schedule

Interval | Check point | Check and measures | Remarks |

|

|

|

|

Weekly | Display unit | Periodically clean the exterior of | CRT screen produces static charge |

|

| display unit using dry soft clean. Use | which would attract dust. DO |

|

| of commercially available CRT | NOT use strong solvent like paint |

|

| cleaner (spray) having antistatic | thinner or abrasive cleaners for |

|

| effect is recommended. | cleaning. |

|

|

| Dust and dirt on CRT creates |

|

|

| symptoms similar to poor |

|

|

| sensitivity. |

|

|

|

|

3 to 6 | Exposed nuts | Check for corroded or loosened nuts | Sealing compound may be used |

months | and bolts on | and bolts. If necessary, clean and | instead of paint. Apply a small |

| antenna unit | repaint them thickly. Replace them if | amount of grease between nuts |

|

| heavily corroded. | and bolts for easy removal in |

|

|

| future. |

|

|

|

|

| Antenna | Check for dirt and cracks on radiator | Do not use plastic solvent |

| radiator | surface. Thick dirt should be wiped | (acetone) for cleaning. If you need |

|

| off with soft cloth dampened with | to remove ice from antenna unit, |

|

| fresh water. if a crack is found, apply | use a wooden hammer or plastic |

|

| a slight amount of sealing compound | head hammer. Crack on the unit |

|

| or adhesive as a temporary remedy, | may cause water ingress, causing |

|

| then call for repair. | serious damages to internal |

|

|

| circuits. |

|

|

|

|

| Terminal strips | Open antenna cover to check | When closing antenna covers in |

| and plugs in | terminal strip and plug connections | position, be careful not to catch |

| antenna unit | inside. Also check the rubber gasket | loose wires between covers and |

|

| of antenna covers for deterioration. | unit. |

|

|

|

|

6 months | CRT and | High voltage at CRT and | If CRT anode rubber cap or wire |

to one | surrounding | surrounding components attract dust | sheath is cracked, ask your dealer |

year | components | in environment which will cause | to replace it. Wait for at least 3 |

|

| poor insulation. Ask your nearest | minutes until high voltage |

|

| FURUNO representative or dealer to | components (CRT and HV |

|

| clean internal | capacitors) discharge their residual |

|

| components. | charges before accessing them. |

|

|

|

|

| Terminal | Check for loose connections. Check |

|

| strips, sockets, | contacts and plugs for proper seating, |

|

| earth terminal | etc. |

|

|

|

|

|

3.2 Life Expectancy of Major Parts

Part | Type |

| Life expectancy | Remarks |

|

|

|

|

|

Antenna | (24 rpm | Gears more than | Wind load | |

motor | (36 rpm) | 10,000 hours | 100 knots | |

|

|

|

| |

Magnetron | MG5232/E3560 (6 kW) |

| ||

| MG5241/E3566 (10 kW) |

|

| |

| 9M752/M5187F (25 kW) |

|

| |

|

|

|

|

|

3 – 2