GENERA OHVI

Air-cooled Recreational Vehicle Generators

This manual should remain with the unit

Model QUIETPACT 40G

HOW TO OBTAIN SERVICE

AUTHORIZED SERVICE DEALER LOCATION

CONTENTS

OPERATION AND MAINTENANCE

Exploded Views and Parts Lists

Part II - Installation Instructions

Safety Rules

Adjustments

during operation. Exercise care near running generators

GENERAL HAZARDS

Despite the safe design of this generator

Parts of the generator are rotating and/or hot

ELECTRICAL HAZARDS

FIRE HAZARDS

EXPLOSION HAZARDS

kW Rating

1.1 GENERATOR IDENTIFICATION

Model 004700-0 - QUIETPACT 40G

Model Number

1.2 GENERATOR APPLICABILITY

1.3 SAFETY

1.5 SPECIFICATIONS

Do not overload the generator. Some installa

1.5.3 ENGINE OIL REQUIREMENTS

Generac does not recommend using any

1.5.5 GENERATOR

1.5.2 FUEL CONSUMPTION

2.2 OPTIONAL REMOTE START/STOP PANEL

2.1.2 START/STOP SWITCH

2.4.1 INSTALLATION

2.1 GENERATOR CONTROL PANEL

2.4.4 COOLING AND VENTILATING AIR

2.5 STARTING THE GENERATOR

2.4.2 ENGINE LUBRICATION

2.4.3 FUEL SUPPLY

2.6 STOPPING THE GENERATOR

2.9.1 LOW OIL PRESSURE SWITCH

2.9.2 HIGH TEMPERATURE SWITCH

Figure 2.2 - Low Oil Pressure and High Temperature Switches

2.9.4 OVERVOLTAGE PROTECTION

2.10 ADDITIONAL INFORMATION

2.9.3 FIELD BOOST

2.10.1 25-HOUR BREAK-IN PERIOD

2.10.4 OPERATION IN HIGH GRASS OR BRUSH

Figure 3.1 - Oil Maintenance Features

3.1 CHECKING THE ENGINE OIL LEVEL

3.2 CHANGING THE ENGINE OIL AND/OR OIL FILTER

3.3.2 CLEANING OR REPLACING THE PAPER FILTER

3.3 MAINTAINING THE ENGINE AIR CLEANER

3.3.1 CLEANING THE FOAM PRECLEANER

Figure 3.2 - Engine Air Cleaner

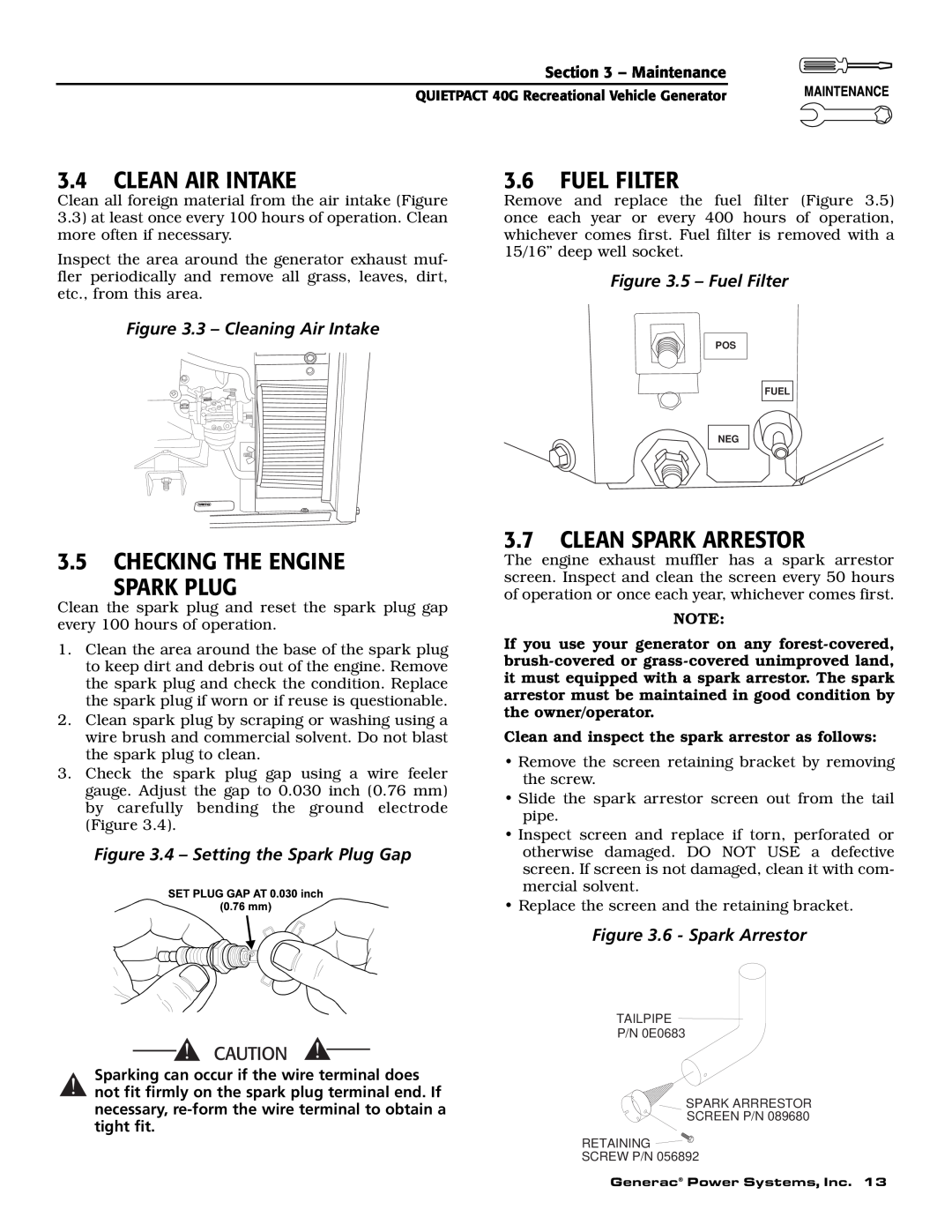

Figure 3.4 - Setting the Spark Plug Gap

3.4 CLEAN AIR INTAKE

3.7 CLEAN SPARK ARRESTOR

Figure 3.3 - Cleaning Air Intake

Use tools with insulated handles Wear rubber gloves and boots

3.8 CLEANING THE GENERATOR

3.9 BATTERY MAINTENANCE

Do NOT use a forceful spray of water to clean

3.12.2 RETURN TO SERVICE

3.12 OUT OF SERVICE PROCEDURE

3.13 ADJUSTING VALVE CLEARANCE

3.12.1 REMOVAL FROM SERVICE

Figure 3.8 - Tightening Jam Nut

3.14 RV GENERATOR SERVICE INTERVAL

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS

INSTALLATION INSTRUCTIONS

SHOULD ATTEMPT INSTALLATION

PART

NOTICE TO INSTALLER

FIRE HAZARDS

1.5 GENERATOR ENGINE OPERATING SPEED

1.2 SAFETY

1.1 PURPOSE AND SCOPE OF THE MANUAL

1.4 EQUIPMENT DESCRIPTION

VIEW FROM TOP

Major Features

2.1.3 SUSPENDED MOUNTING

2.1 LOCATION AND SUPPORT

2.1.1 GENERATOR LOCATION

2.1.2 GENERATOR SUPPORT

2.2.1 COMPARTMENT SIZE

2.2 GENERATOR COMPARTMENTS

2.1.4 GENERATOR RESTRAINT

2.2.2 COMPARTMENT CONSTRUCTION

2.2.4 ACOUSTICS

2.2.3 SOUND INSULATING MATERIALS

Figure 2.6 - Types of Lock Seams

All measurements are in millimeters, 25.4 mm = 1”

Figure 2.7 - Typical Noise Abatement 2.2.5 COMPARTMENT FLOOR CUTOUTS

Figure 2.8 - Compartment Floor Cutout Drawing 0D8716-C

VIEW FROM TOP

2.3.1 GENERATOR AIRFLOW

2.3.2 TESTING THE INSTALLATION

2.3 COOLING AND VENTILATING AIR

2.4 GASOLINE FUEL SYSTEM

2.4.2 GENERATOR FUEL SUPPLY LINE 2.4.2.1 Rigid Fuel Lines

2.5 EXHAUST SYSTEM

2.4.1 FUEL TANK

2.4.2.2 Flexible Fuel Line

2.5.1 SPARK ARRESTOR

2.5.2 EXHAUST SYSTEM SAFETY

Figure 2.12 - Spark Arrestor Installation

2.6 ELECTRICAL CONNECTIONS

2.6.4 CONDUIT

2.6.2 WIRING

2.6.1 ELECTRICAL JUNCTION BOX

2.6.3 GENERATOR AC CONNECTIONS

2.6.5 ISOLATING DIFFERENT POWER SOURCES

2.6.6 POWER SUPPLY CORD

Figure 2.14 - Transfer Switch Isolation Method

2.7.2 BATTERY CABLES

2.7 BATTERY INSTALLATION

2.8 OPTIONAL ACCESSORIES

2.7.1 RECOMMENDED BATTERY

3.2 BEFORE INITIAL START-UP

3.1 POST INSTALLATION TESTS

3.4 TESTING UNDER LOAD

Do not make any unnecessary adjustments

3.5 INSTALLATION CHECKLIST

34 Generac Power Systems, Inc

Appendix 1 - Notes

CORRECTION

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

Appendix 3 - Electrical Data

36 Generac Power Systems, Inc

BROWN

Appendix 3 - Electrical

Data

Power

QUIETPACT

TO CARB

38 Generac Power Systems, Inc

Appendix 4 - Exploded Views and Parts Lists

Enclosure - Drawing No. 0D8352-E

Appendix 4 - Exploded Views and Parts Lists

PART NO. QTY

DESCRIPTION

40 Generac Power Systems, Inc

DESCRIPTION

25 24

42 Generac Power Systems, Inc

DESCRIPTION

44 Generac Power Systems, Inc

GASKET CARBURETOR/MANIFOLD

ASSEMBLY BRACKET GOVERNOR

BOOT CHOKE SOLENOID PLASTIC

ASSEMBLY, GOVERNOR LEVER

46 Generac Power Systems, Inc

OIL PRESSURE RELIEF COVER

TAPERED CRANKSHAFT ASSEMBLY

SCREW, HHFC M8-1.25 X 35MM

VALVE SPRING WEAR WASHER

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES

CALIFORNIA AND FEDERAL EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

MANUFACTURER’S EMISSION CONTROL SYSTEM WARRANTY COVERAGE

3 Recreational Vehicle RV Generator 4 Industrial Mobile IM Generator

EMISSION CONTROL SYSTEM WARRANTY

EMISSION RELATED PARTS INCLUDE THE FOLLOWING

1 Utility 2 Lawn and Garden Equipment

GENERAC POWER SYSTEMS, INC

GENERAC POWER SYSTEMS’ THREE-YEAR LIMITED WARRANTY

WARRANTY SCHEDULE - COMMERCIAL APPLICATIONS

WARRANTY SCHEDULE - CONSUMER/PERSONAL APPLICATIONS