A/GPG13 M specifications

Goodman Manufacturing is known for producing high-quality HVAC systems, and one of its standout offerings is the Goodman A/GPG13 M series. This air conditioning and heating unit delivers exceptional performance, reliability, and efficiency, making it a preferred choice for residential settings.The Goodman A/GPG13 M is specifically designed to provide homeowners with an efficient and affordable solution for climate control. One of its main features is the energy-efficient compressor, which operates with a SEER rating of up to 13, ensuring reduced electricity consumption while effectively cooling your living space. This efficiency not only minimizes utility bills but also helps to lower your carbon footprint.

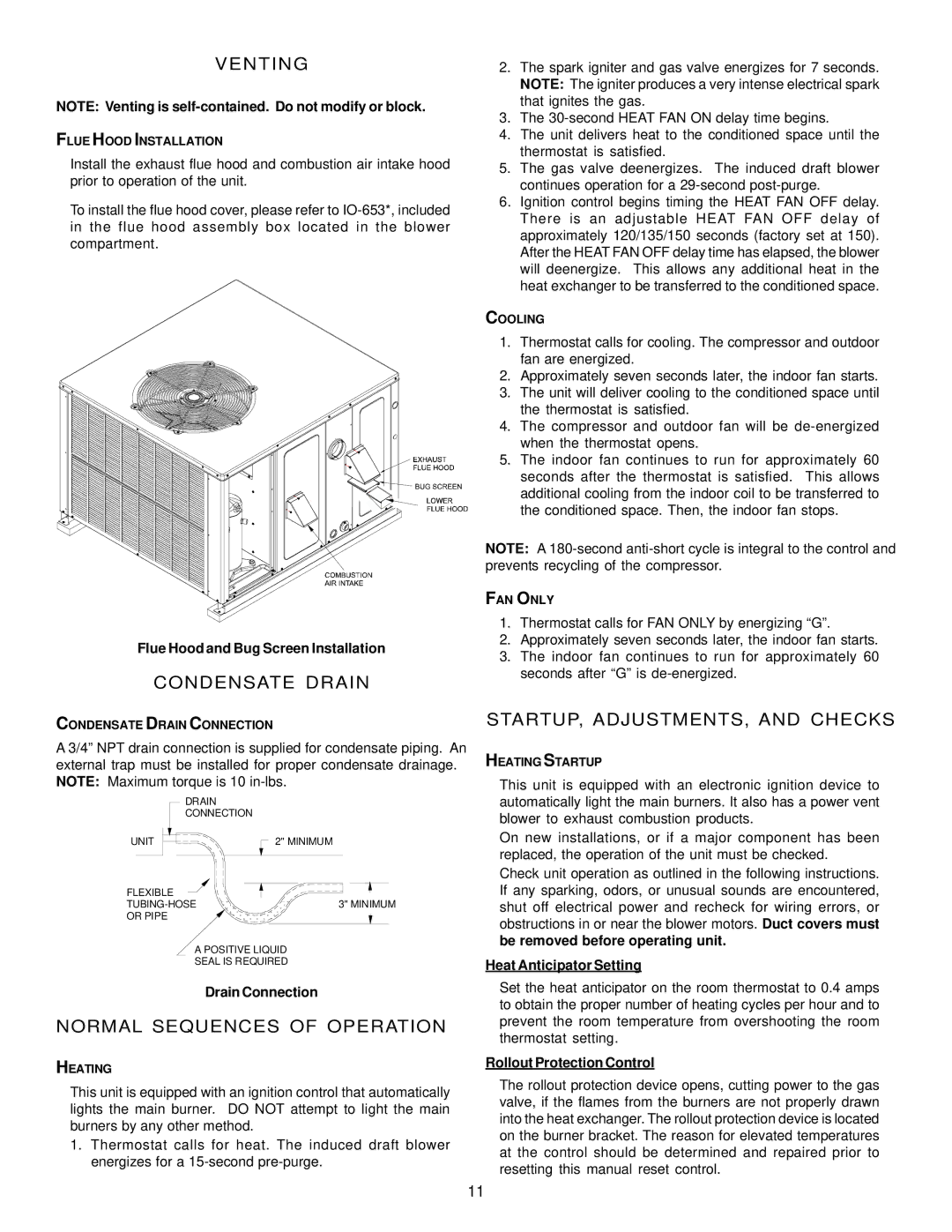

Another standout characteristic of the Goodman A/GPG13 M is its durable construction. The unit is engineered with a heavy-gauge, galvanized steel cabinet that has a polyester finish, providing protection against rust and corrosion. This durability ensures that the system can withstand the elements and lasting performance even in challenging climates.

The Goodman A/GPG13 M series also boasts advanced technology to enhance comfort levels in any home. The unit is equipped with a two-stage cooling system that can adjust to varying temperature demands, ensuring that your living space remains comfortable throughout the hot summer months. Additionally, the unit includes a multi-speed blower for more even air distribution, enhancing overall comfort.

Furthermore, the Goodman A/GPG13 M complies with rigorous environmental standards. It uses R-410A refrigerant, which is more environmentally friendly than older refrigerants like R-22, making it an excellent choice for eco-conscious consumers.

Installation of the Goodman A/GPG13 M is made easier with its lightweight design and user-friendly features, allowing HVAC professionals to install the system efficiently. The unit is backed by a comprehensive warranty, reflecting Goodman Manufacturing’s commitment to quality and customer satisfaction.

In summary, the Goodman A/GPG13 M series showcases an impressive combination of energy efficiency, durable construction, advanced technology, and eco-friendly refrigerant choices. It represents an ideal option for homeowners who seek a reliable HVAC solution that delivers consistent comfort while maintaining an eye on energy consumption and environmental impact.