SERVICING

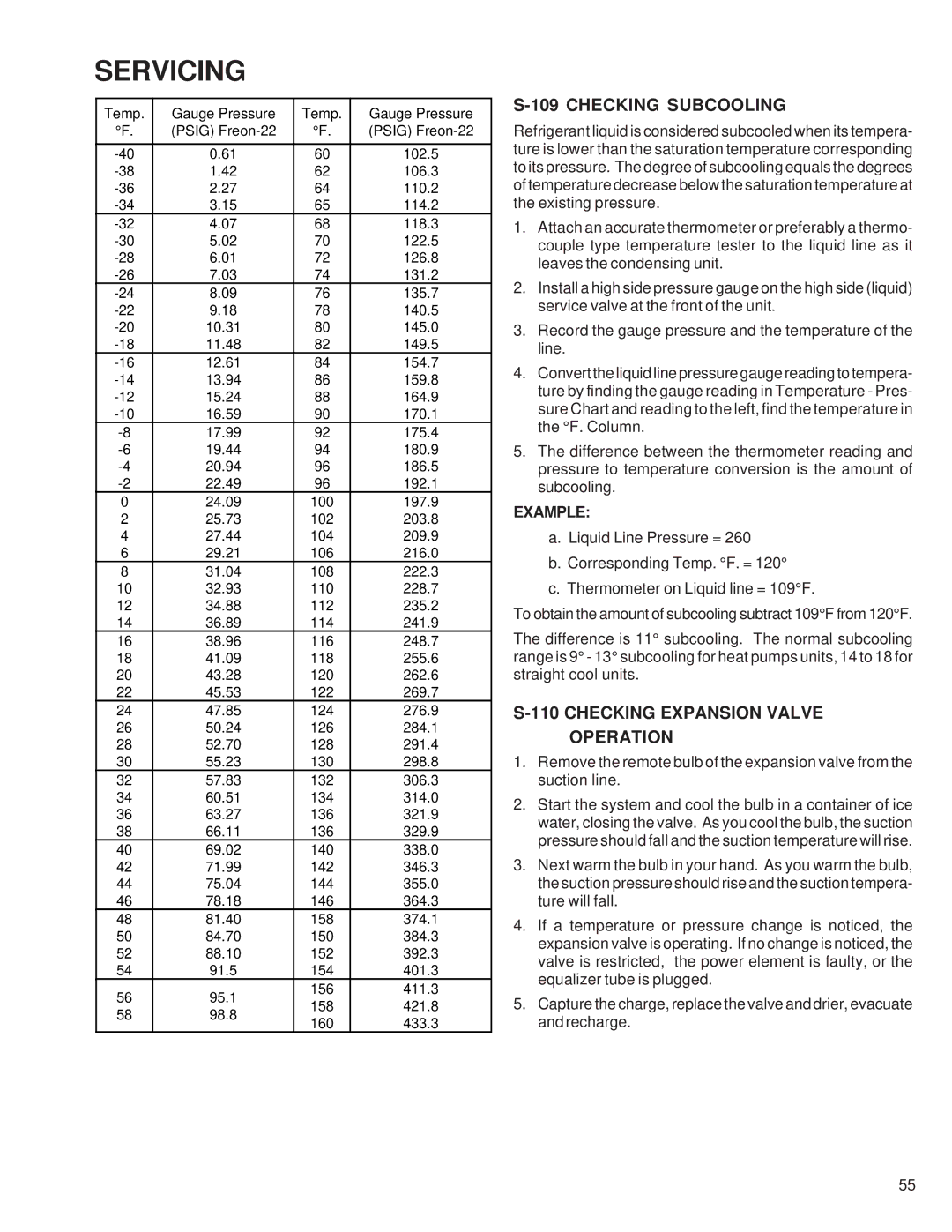

Temp. | Gauge Pressure | Temp. | Gauge Pressure | |

°F. | (PSIG) | °F. | (PSIG) | |

|

|

|

| |

0.61 | 60 | 102.5 | ||

1.42 | 62 | 106.3 | ||

2.27 | 64 | 110.2 | ||

3.15 | 65 | 114.2 | ||

4.07 | 68 | 118.3 | ||

5.02 | 70 | 122.5 | ||

6.01 | 72 | 126.8 | ||

7.03 | 74 | 131.2 | ||

8.09 | 76 | 135.7 | ||

9.18 | 78 | 140.5 | ||

10.31 | 80 | 145.0 | ||

11.48 | 82 | 149.5 | ||

12.61 | 84 | 154.7 | ||

13.94 | 86 | 159.8 | ||

15.24 | 88 | 164.9 | ||

16.59 | 90 | 170.1 | ||

17.99 | 92 | 175.4 | ||

19.44 | 94 | 180.9 | ||

20.94 | 96 | 186.5 | ||

22.49 | 96 | 192.1 | ||

0 | 24.09 | 100 | 197.9 | |

2 | 25.73 | 102 | 203.8 | |

4 | 27.44 | 104 | 209.9 | |

6 | 29.21 | 106 | 216.0 | |

8 | 31.04 | 108 | 222.3 | |

10 | 32.93 | 110 | 228.7 | |

12 | 34.88 | 112 | 235.2 | |

14 | 36.89 | 114 | 241.9 | |

16 | 38.96 | 116 | 248.7 | |

18 | 41.09 | 118 | 255.6 | |

20 | 43.28 | 120 | 262.6 | |

22 | 45.53 | 122 | 269.7 | |

24 | 47.85 | 124 | 276.9 | |

26 | 50.24 | 126 | 284.1 | |

28 | 52.70 | 128 | 291.4 | |

30 | 55.23 | 130 | 298.8 | |

32 | 57.83 | 132 | 306.3 | |

34 | 60.51 | 134 | 314.0 | |

36 | 63.27 | 136 | 321.9 | |

38 | 66.11 | 136 | 329.9 | |

40 | 69.02 | 140 | 338.0 | |

42 | 71.99 | 142 | 346.3 | |

44 | 75.04 | 144 | 355.0 | |

46 | 78.18 | 146 | 364.3 | |

48 | 81.40 | 158 | 374.1 | |

50 | 84.70 | 150 | 384.3 | |

52 | 88.10 | 152 | 392.3 | |

54 | 91.5 | 154 | 401.3 | |

56 | 95.1 | 156 | 411.3 | |

158 | 421.8 | |||

58 | 98.8 | |||

160 | 433.3 | |||

|

|

S-109 CHECKING SUBCOOLING

Refrigerant liquid is considered subcooled when its tempera- ture is lower than the saturation temperature corresponding to its pressure. The degree of subcooling equals the degrees of temperature decrease below the saturation temperature at the existing pressure.

1.Attach an accurate thermometer or preferably a thermo- couple type temperature tester to the liquid line as it leaves the condensing unit.

2.Install a high side pressure gauge on the high side (liquid) service valve at the front of the unit.

3.Record the gauge pressure and the temperature of the line.

4.Convert the liquid line pressure gauge reading to tempera- ture by finding the gauge reading in Temperature - Pres- sure Chart and reading to the left, find the temperature in the °F. Column.

5.The difference between the thermometer reading and pressure to temperature conversion is the amount of subcooling.

EXAMPLE:

a.Liquid Line Pressure = 260

b.Corresponding Temp. °F. = 120°

c.Thermometer on Liquid line = 109°F.

To obtain the amount of subcooling subtract 109°F from 120°F.

The difference is 11° subcooling. The normal subcooling range is 9° - 13° subcooling for heat pumps units, 14 to 18 for straight cool units.

S-110 CHECKING EXPANSION VALVE OPERATION

1.Remove the remote bulb of the expansion valve from the suction line.

2.Start the system and cool the bulb in a container of ice water, closing the valve. As you cool the bulb, the suction pressure should fall and the suction temperature will rise.

3.Next warm the bulb in your hand. As you warm the bulb, the suction pressure should rise and the suction tempera- ture will fall.

4.If a temperature or pressure change is noticed, the expansion valve is operating. If no change is noticed, the valve is restricted, the power element is faulty, or the equalizer tube is plugged.

5.Capture the charge, replace the valve and drier, evacuate and recharge.

55