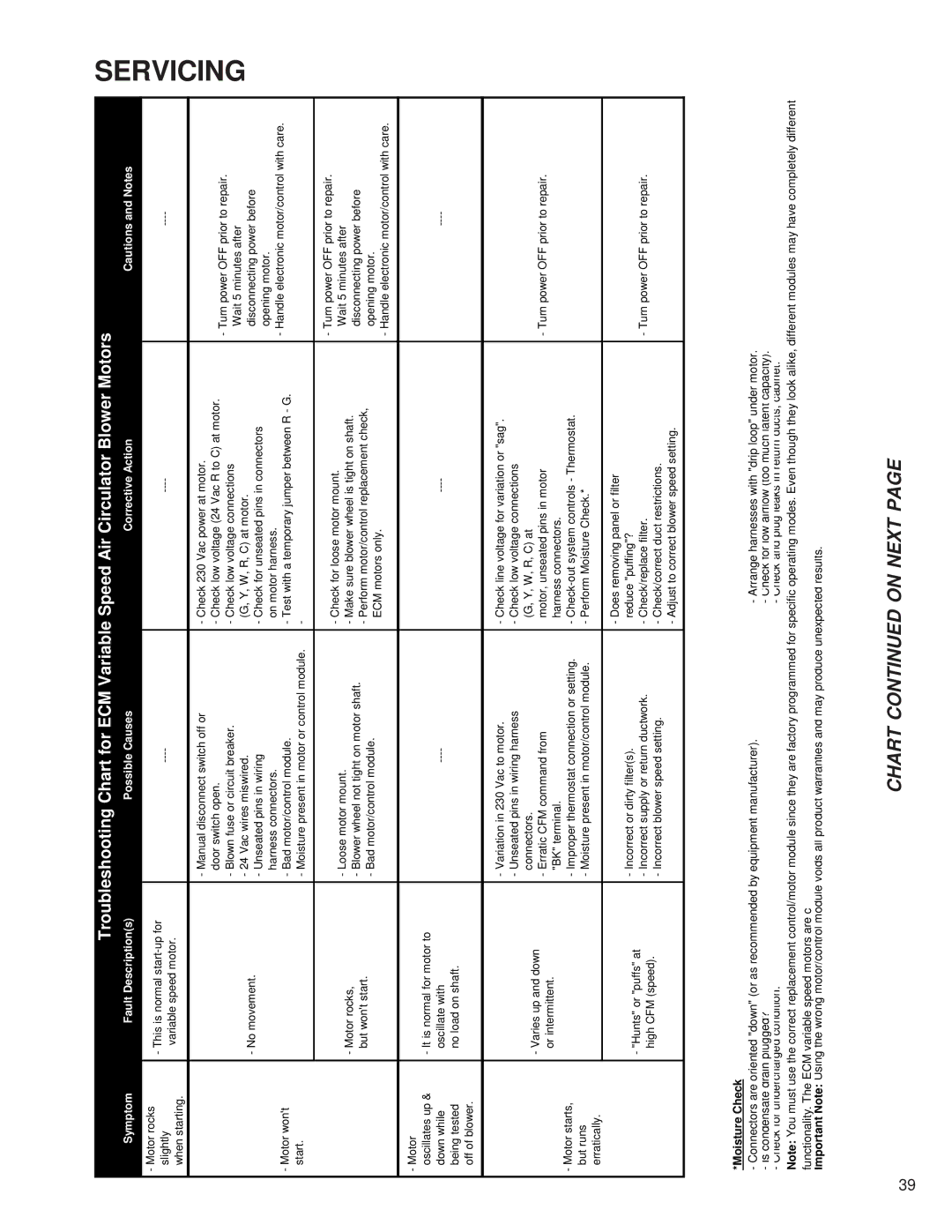

| Troubleshooting Chart for ECM Variable Speed Air Circulator Blower Motors | SERVICING | |||

|

| ||||

Symptom | Fault Description(s) | Possible Causes | Corrective Action | Cautions and Notes |

|

|

|

|

|

|

|

- Motor rocks | - This is normal |

| |||

slightly |

| ||||

variable speed motor. |

| ||||

when starting. |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

| - Manual disconnect switch off or | - Check 230 Vac power at motor. |

|

|

|

| door switch open. | - Check low voltage (24 Vac R to C) at motor. | - Turn power OFF prior to repair. |

|

|

| - Blown fuse or circuit breaker. | - Check low voltage connections |

| |

|

| Wait 5 minutes after |

| ||

|

| - 24 Vac wires miswired. | (G, Y, W, R, C) at motor. |

| |

| - No movement. | disconnecting power before |

| ||

| - Unseated pins in wiring | - Check for unseated pins in connectors |

| ||

|

| opening motor. |

| ||

|

| harness connectors. | on motor harness. |

| |

- Motor won't |

| - Handle electronic motor/control with care. |

| ||

| - Bad motor/control module. | - Test with a temporary jumper between R - G. |

| ||

|

|

| |||

start. |

| - Moisture present in motor or control module. | - |

|

|

|

|

|

|

|

|

|

| - Loose motor mount. | - Check for loose motor mount. | - Turn power OFF prior to repair. |

|

|

| Wait 5 minutes after |

| ||

| - Motor rocks, | - Make sure blower wheel is tight on shaft. |

| ||

| - Blower wheel not tight on motor shaft. | disconnecting power before |

| ||

| but won't start. | - Perform motor/control replacement check, |

| ||

| - Bad motor/control module. | opening motor. |

| ||

|

| ECM motors only. |

| ||

|

|

| - Handle electronic motor/control with care. |

| |

|

|

|

|

| |

|

|

|

|

|

|

- Motor |

|

|

|

|

|

oscillates up & | - It is normal for motor to |

|

|

|

|

down while | oscillate with |

| |||

being tested | no load on shaft. |

|

|

|

|

off of blower. |

|

|

|

|

|

|

|

|

|

|

|

|

| - Variation in 230 Vac to motor. | - Check line voltage for variation or "sag". |

|

|

|

| - Unseated pins in wiring harness | - Check low voltage connections |

|

|

| - Varies up and down | connectors. | (G, Y, W, R, C) at | - Turn power OFF prior to repair. |

|

| - Erratic CFM command from | motor, unseated pins in motor |

| ||

| or intermittent. |

| |||

| "BK" terminal. | harness connectors. |

|

| |

- Motor starts, |

|

|

| ||

| - Improper thermostat connection or setting. | - |

|

| |

but runs |

| - Moisture present in motor/control module. | - Perform Moisture Check.* |

|

|

erratically. |

|

|

|

|

|

|

|

| - Does removing panel or filter |

|

|

| - "Hunts" or "puffs" at | - Incorrect or dirty filter(s). | reduce "puffing"? |

|

|

| - Incorrect supply or return ductwork. | - Check/replace filter. | - Turn power OFF prior to repair. |

| |

| high CFM (speed). |

| |||

| - Incorrect blower speed setting. | - Check/correct duct restrictions. |

|

| |

|

|

|

| ||

|

|

| - Adjust to correct blower speed setting. |

|

|

|

|

|

|

|

|

*Moisture Check

-Connectors are oriented "down" (or as recommended by equipment manufacturer).

-Is condensate drain plugged?

-Check for undercharged condition.

-Arrange harnesses with "drip loop" under motor.

-Check for low airflow (too much latent capacity).

-Check and plug leaks in return ducts, cabinet.

Note: You must use the correct replacement control/motor module since they are factory programmed for specific operating modes. Even though they look alike, different modules may have completely different

functionality. The ECM variable speed motors are c

Important Note: Using the wrong motor/control module voids all product warranties and may produce unexpected results.

39