Setup

Level Sensor Calibration

Setup

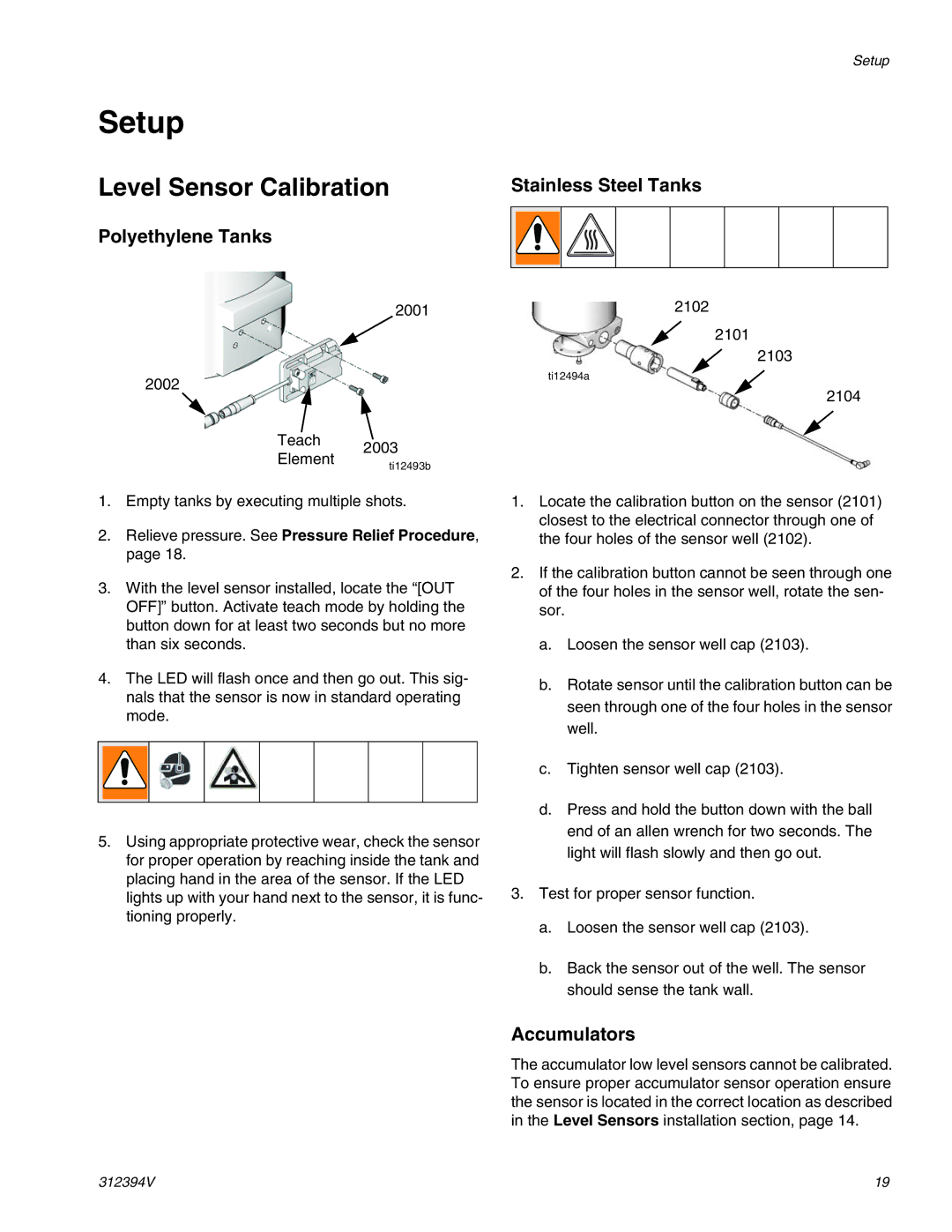

Stainless Steel Tanks

Polyethylene Tanks

2001

2002

Teach 2003

Element

ti12493b

1.Empty tanks by executing multiple shots.

2.Relieve pressure. See Pressure Relief Procedure, page 18.

3.With the level sensor installed, locate the “[OUT OFF]” button. Activate teach mode by holding the button down for at least two seconds but no more than six seconds.

4.The LED will flash once and then go out. This sig- nals that the sensor is now in standard operating mode.

5.Using appropriate protective wear, check the sensor for proper operation by reaching inside the tank and placing hand in the area of the sensor. If the LED lights up with your hand next to the sensor, it is func- tioning properly.

2102

2101

2103

ti12494a

2104

1.Locate the calibration button on the sensor (2101) closest to the electrical connector through one of the four holes of the sensor well (2102).

2.If the calibration button cannot be seen through one of the four holes in the sensor well, rotate the sen- sor.

a.Loosen the sensor well cap (2103).

b.Rotate sensor until the calibration button can be seen through one of the four holes in the sensor well.

c.Tighten sensor well cap (2103).

d.Press and hold the button down with the ball end of an allen wrench for two seconds. The light will flash slowly and then go out.

3.Test for proper sensor function.

a.Loosen the sensor well cap (2103).

b.Back the sensor out of the well. The sensor should sense the tank wall.

Accumulators

The accumulator low level sensors cannot be calibrated. To ensure proper accumulator sensor operation ensure the sensor is located in the correct location as described in the Level Sensors installation section, page 14.

312394V | 19 |