Installation

NOTE: Be careful not to cut or nick copper strands. If more than five strands are cut or nicked, trim wire and

New hoses are

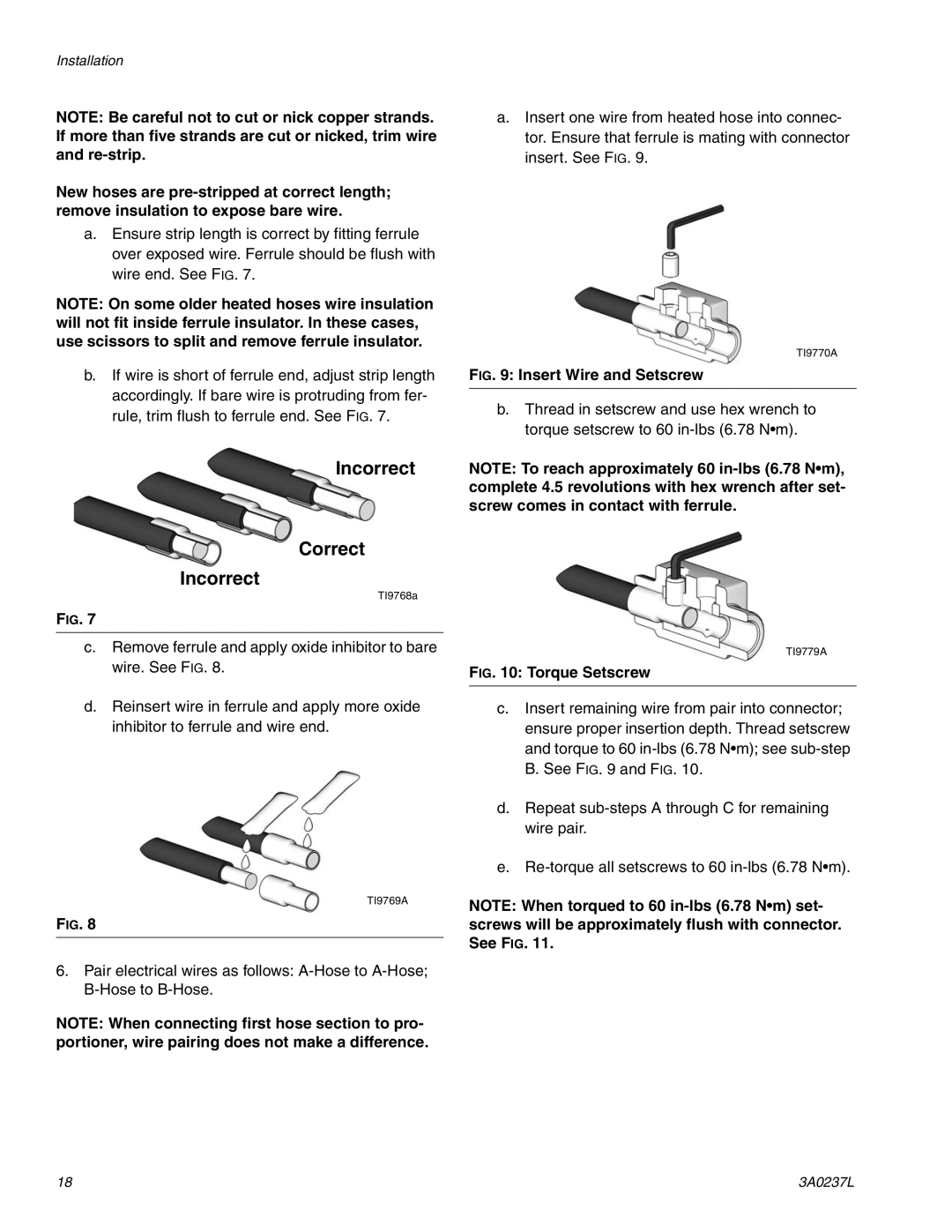

a.Ensure strip length is correct by fitting ferrule over exposed wire. Ferrule should be flush with wire end. See FIG. 7.

NOTE: On some older heated hoses wire insulation will not fit inside ferrule insulator. In these cases, use scissors to split and remove ferrule insulator.

b.If wire is short of ferrule end, adjust strip length accordingly. If bare wire is protruding from fer- rule, trim flush to ferrule end. See FIG. 7.

Incorrect

Correct

Incorrect

TI9768a

FIG. 7

c.Remove ferrule and apply oxide inhibitor to bare wire. See FIG. 8.

d.Reinsert wire in ferrule and apply more oxide inhibitor to ferrule and wire end.

TI9769A

FIG. 8

6.Pair electrical wires as follows:

NOTE: When connecting first hose section to pro- portioner, wire pairing does not make a difference.

a.Insert one wire from heated hose into connec- tor. Ensure that ferrule is mating with connector insert. See FIG. 9.

TI9770A

FIG. 9: Insert Wire and Setscrew

b.Thread in setscrew and use hex wrench to torque setscrew to 60

NOTE: To reach approximately 60

TI9779A

FIG. 10: Torque Setscrew

c.Insert remaining wire from pair into connector; ensure proper insertion depth. Thread setscrew and torque to 60

d.Repeat

e.

NOTE: When torqued to 60

18 | 3A0237L |