3.Raise the table until the gauge blocks just touch the drum.

Note: A good way to know when they are touching is to rock the drum back and forth while raising the table until you hear or feel contact with the gauge blocks.

4.Lower the table one full crank of the handwheel (taking handwheel

5.Starting at one end, find the largest size feeler gauge that can pass between the drum and your gauge block. (The feeler gauge should slide with moderate resistance, without forc- ing the drum to roll.)

6.Repeat Step 5 at the other end of the drum.

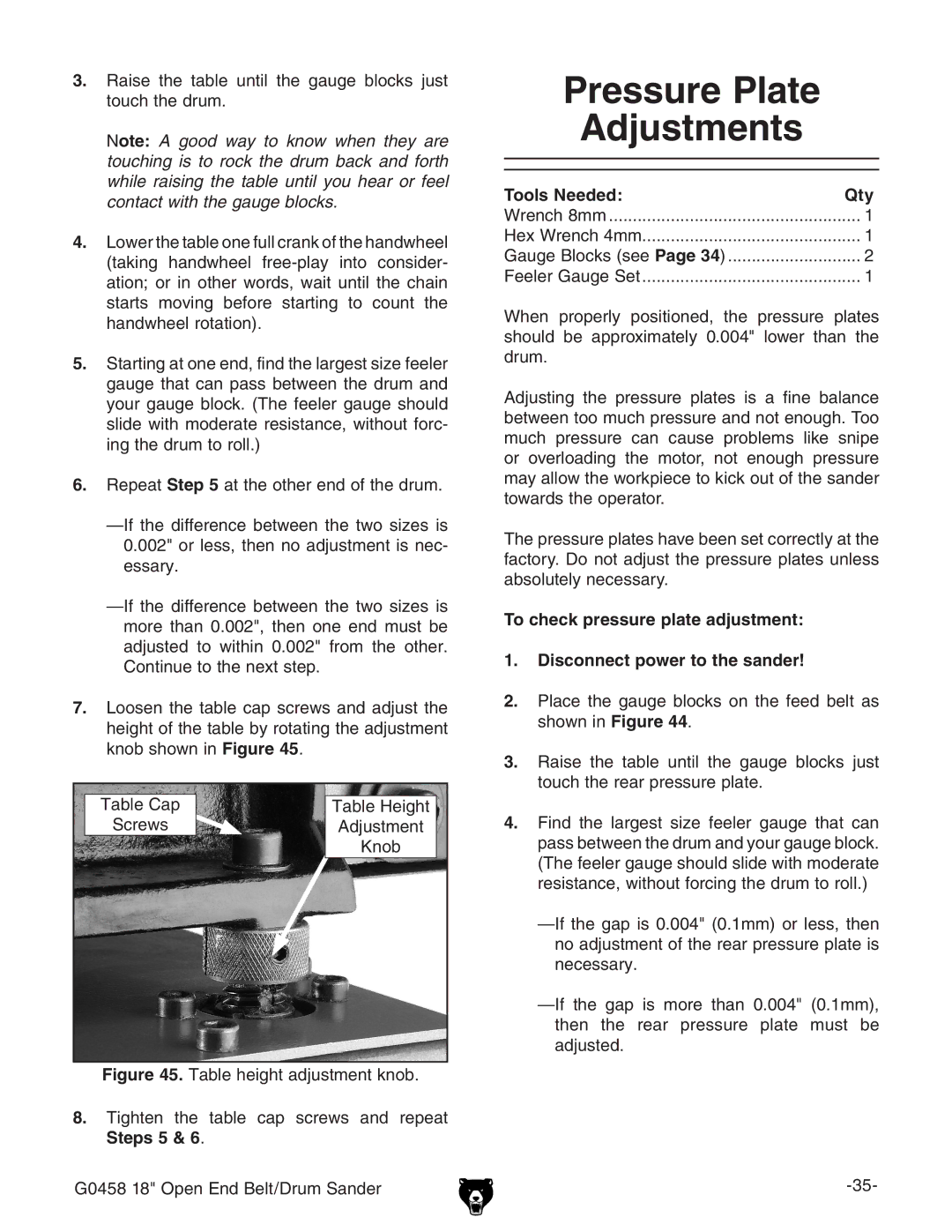

7.Loosen the table cap screws and adjust the height of the table by rotating the adjustment knob shown in Figure 45.

Table Cap |

| Table Height |

Screws |

| Adjustment |

|

| Knob |

Figure 45. Table height adjustment knob.

8.Tighten the table cap screws and repeat Steps 5 & 6.

G0458 18" Open End Belt/Drum Sander

Pressure Plate |

|

Adjustments |

|

Tools Needed: | Qty |

Wrench 8mm | 1 |

Hex Wrench 4mm | 1 |

Gauge Blocks (see Page 34) | 2 |

Feeler Gauge Set | 1 |

When properly positioned, the pressure plates should be approximately 0.004" lower than the drum.

Adjusting the pressure plates is a fine balance between too much pressure and not enough. Too much pressure can cause problems like snipe or overloading the motor, not enough pressure may allow the workpiece to kick out of the sander towards the operator.

The pressure plates have been set correctly at the factory. Do not adjust the pressure plates unless absolutely necessary.

To check pressure plate adjustment:

1.Disconnect power to the sander!

2.Place the gauge blocks on the feed belt as shown in Figure 44.

3.Raise the table until the gauge blocks just touch the rear pressure plate.

4.Find the largest size feeler gauge that can pass between the drum and your gauge block. (The feeler gauge should slide with moderate resistance, without forcing the drum to roll.)