lubrication

Lubrication

For the many moving parts of the Model G0641, there are three lubrication systems: 1) the pneu- matic oiler attached to the air

2)the lower pivot arm automatic oil system, and

3)manual lubrication of the arbor housings and remaining pivot points.

The pneumatic oiler injects lubrication into the air system as it is used to keep the main and hold- down pneumatic rams moving smoothly.

To lubricate the pneumatic system:

1.DISCONNECT SAW FROM AIR SUPPLY!

2.Fill the oil reservoir with

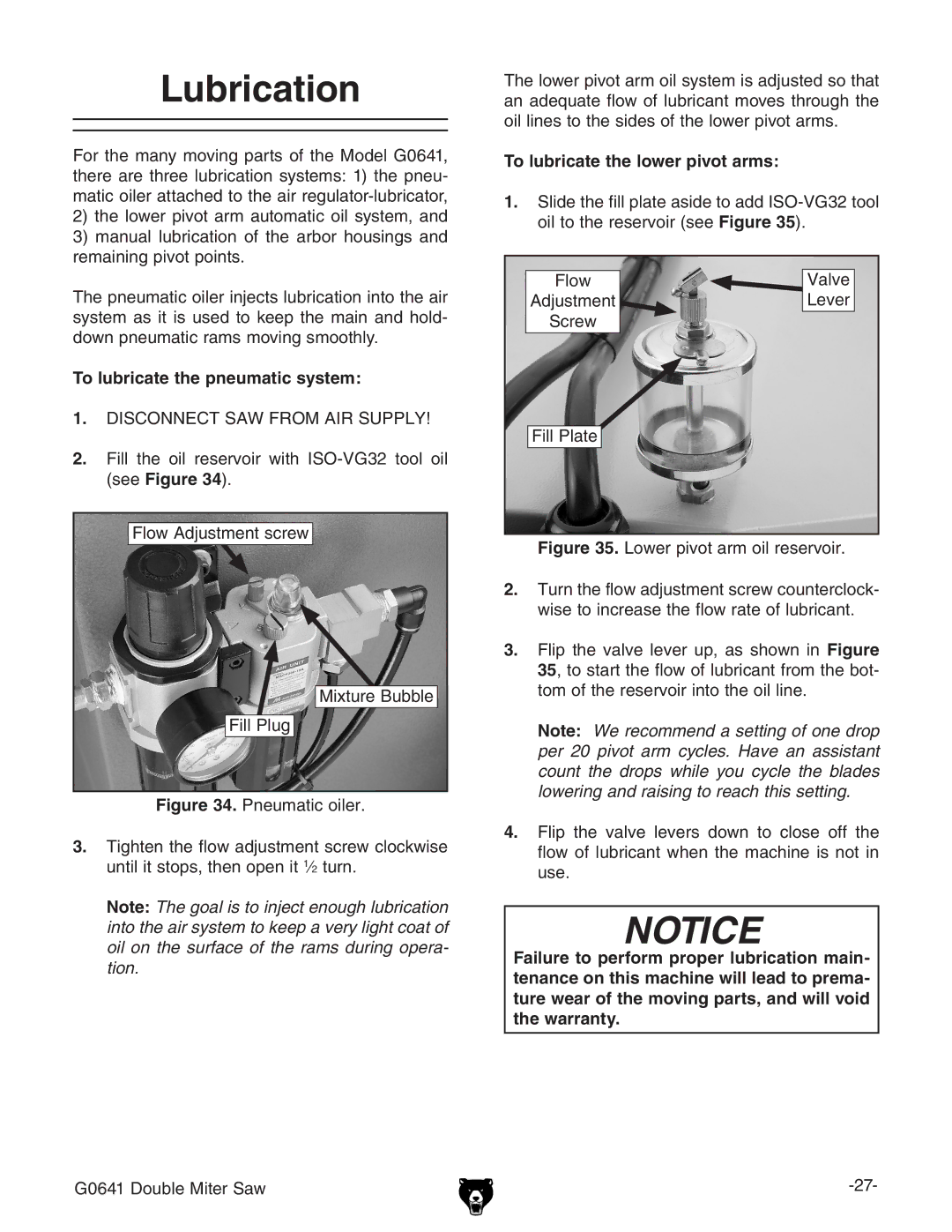

Flow Adjustment screw |

Mixture Bubble |

Fill Plug |

Figure 34. Pneumatic oiler.

3.Tighten the flow adjustment screw clockwise until it stops, then open it 1⁄2 turn.

Note: The goal is to inject enough lubrication into the air system to keep a very light coat of oil on the surface of the rams during opera- tion.

G0641 Double Miter Saw

The lower pivot arm oil system is adjusted so that an adequate flow of lubricant moves through the oil lines to the sides of the lower pivot arms.

To lubricate the lower pivot arms:

1.Slide the fill plate aside to add

Flow | Valve |

Adjustment | Lever |

Screw |

|

Fill Plate |

|

Figure 35. Lower pivot arm oil reservoir.

2.Turn the flow adjustment screw counterclock- wise to increase the flow rate of lubricant.

3.Flip the valve lever up, as shown in Figure 35, to start the flow of lubricant from the bot- tom of the reservoir into the oil line.

Note: We recommend a setting of one drop per 20 pivot arm cycles. Have an assistant count the drops while you cycle the blades lowering and raising to reach this setting.

4.Flip the valve levers down to close off the flow of lubricant when the machine is not in use.

NOTICE

Failure to perform proper lubrication main- tenance on this machine will lead to prema- ture wear of the moving parts, and will void the warranty.