You need to change coolant when you notice the following conditions:

•Low sump level

•Abnormal fluid appearance (change in color)

•Foul smell (rancidity)

•Floating matter on the fluid (chips, swarf, mold)

•Tramp oil floating on the surface (leaking machine and hydraulic oils)

•Excessive foam (improper mixture, too high of pressure, excessive air in system)

•Dirty machine or trenches (cleaners in the fluid have become depleted)

•User notices skin irritation

•User has respiratory irritation

•Other problems that might be fluid related are:

or tool)

Consult your coolant manufacturer and MSDS for complete use and disposal information.

Model G0717 (Mfg. Since 9/10)

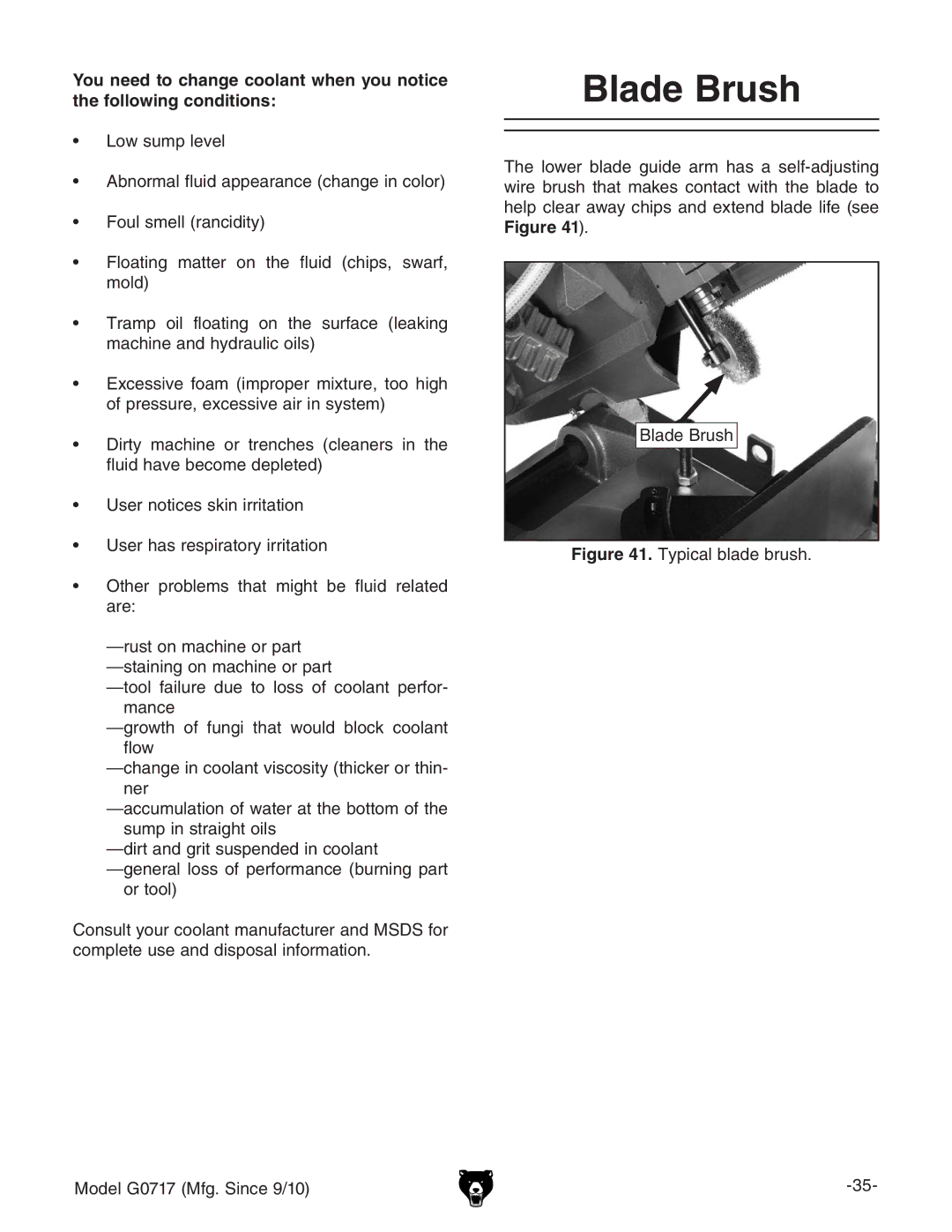

Blade Brush

The lower blade guide arm has a

Blade Brush