Blade Care &

Break-In

Blade Care

To prolong blade life, always use a blade with the proper width, set, type, and pitch for each applica- tion. Maintain the appropriate feed rate, feed pres- sure, and blade speed and pay attention to the chip characteristics (Refer to the Chip Inspection Chart on Page 31). Keep your blades clean, since dirty or gummed up blades pass through the cutting material with much more resistance than clean blades, causing unnecessary heat.

Blade Break-In

The tips and edges of a new blade are extremely sharp. Cutting at too fast of a feed rate or too slow of a blade speed can fracture these tips and edges, quickly dulling the blade. Properly break-

Use the Chip Inspection Chart on Page 31 as a guide to evaluate the chips and ensure that the optimal blade speed and feed rate are being used.

To properly break-in a new blade:

1.Choose the correct speed for the blade and material of the operation.

2.Reduce the feed pressure by half for the first

3.To avoid twisting the blade when cutting, adjust the feed pressure when the total width of the blade is in the cut.

Downfeed

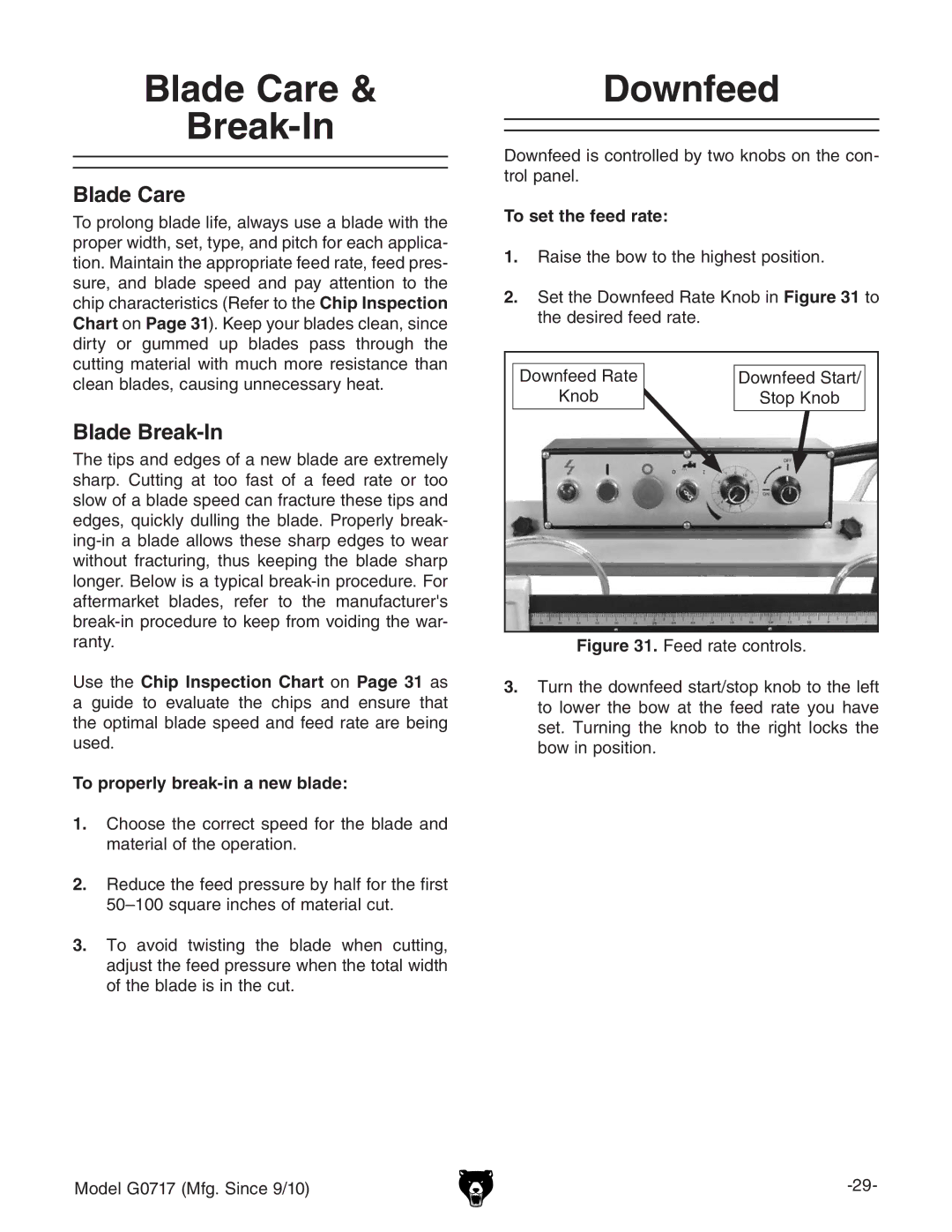

Downfeed is controlled by two knobs on the con- trol panel.

To set the feed rate:

1.Raise the bow to the highest position.

2.Set the Downfeed Rate Knob in Figure 31 to the desired feed rate.

Downfeed Rate | Downfeed Start/ |

Knob | Stop Knob |

Figure 31. Feed rate controls.

3.Turn the downfeed start/stop knob to the left to lower the bow at the feed rate you have set. Turning the knob to the right locks the bow in position.

Model G0717 (Mfg. Since 9/10) |