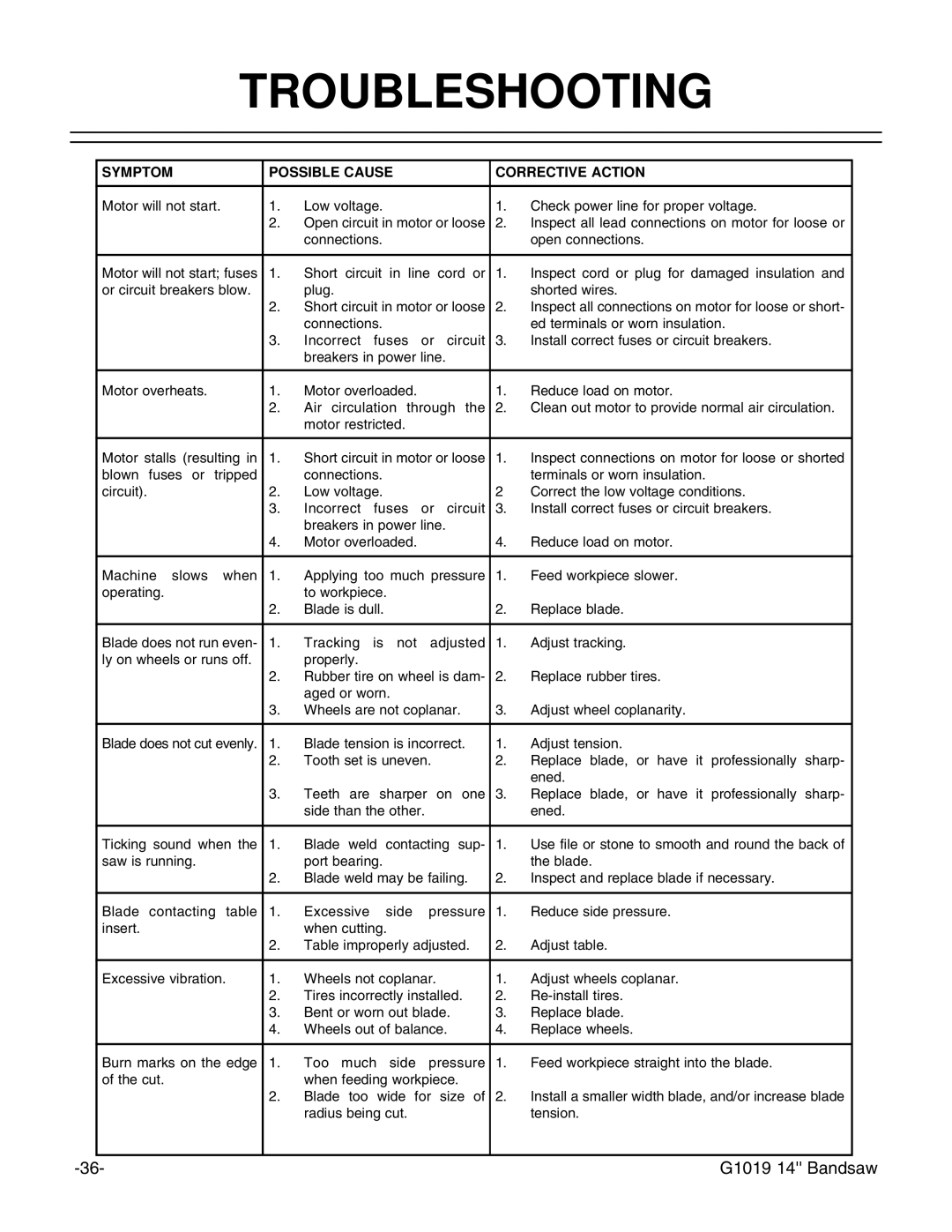

TROUBLESHOOTING

SYMPTOM |

| POSSIBLE CAUSE |

|

|

| CORRECTIVE ACTION | |||

Motor will not start. | 1. | Low voltage. |

|

|

| 1. | Check power line for proper voltage. | ||

|

| 2. | Open circuit in motor or loose | 2. | Inspect all lead connections on motor for loose or | ||||

|

|

| connections. |

|

|

|

| open connections. | |

|

|

|

|

| |||||

Motor will not start; fuses | 1. | Short circuit in line cord or | 1. | Inspect cord or plug for damaged insulation and | |||||

or circuit breakers blow. |

| plug. |

|

|

|

|

| shorted wires. | |

|

| 2. | Short circuit in motor or loose | 2. | Inspect all connections on motor for loose or short- | ||||

|

|

| connections. |

|

|

|

| ed terminals or worn insulation. | |

|

| 3. | Incorrect | fuses | or | circuit | 3. | Install correct fuses or circuit breakers. | |

|

|

| breakers in power line. |

|

|

| |||

|

|

|

|

|

|

|

| ||

Motor overheats. |

| 1. | Motor overloaded. |

|

| 1. | Reduce load on motor. | ||

|

| 2. | Air circulation | through the | 2. | Clean out motor to provide normal air circulation. | |||

|

|

| motor restricted. |

|

|

|

| ||

|

|

|

|

| |||||

Motor stalls (resulting in | 1. | Short circuit in motor or loose | 1. | Inspect connections on motor for loose or shorted | |||||

blown fuses or | tripped |

| connections. |

|

|

|

| terminals or worn insulation. | |

circuit). |

| 2. | Low voltage. |

|

|

| 2 | Correct the low voltage conditions. | |

|

| 3. | Incorrect | fuses | or | circuit | 3. | Install correct fuses or circuit breakers. | |

|

|

| breakers in power line. |

|

|

| |||

|

| 4. | Motor overloaded. |

|

| 4. | Reduce load on motor. | ||

|

|

|

|

|

| ||||

Machine slows | when | 1. | Applying too much pressure | 1. | Feed workpiece slower. | ||||

operating. |

|

| to workpiece. |

|

|

|

|

| |

|

| 2. | Blade is dull. |

|

|

| 2. | Replace blade. | |

|

|

|

|

|

|

|

| ||

Blade does not run even- | 1. | Tracking | is | not | adjusted | 1. | Adjust tracking. | ||

ly on wheels or runs off. |

| properly. |

|

|

|

|

|

| |

|

| 2. | Rubber tire on wheel is dam- | 2. | Replace rubber tires. | ||||

|

|

| aged or worn. |

|

|

|

|

| |

|

| 3. | Wheels are not coplanar. | 3. | Adjust wheel coplanarity. | ||||

|

|

|

|

| |||||

Blade does not cut evenly. | 1. | Blade tension is incorrect. | 1. | Adjust tension. | |||||

|

| 2. | Tooth set is uneven. |

| 2. | Replace blade, or have it professionally sharp- | |||

|

|

|

|

|

|

|

|

| ened. |

3.Teeth are sharper on one 3. Replace blade, or have it professionally sharp-

|

| side than the other. |

| ened. |

|

|

|

| |

Ticking sound when the | 1. | Blade weld contacting sup- 1. | Use file or stone to smooth and round the back of | |

saw is running. |

| port bearing. |

| the blade. |

| 2. | Blade weld may be failing. | 2. | Inspect and replace blade if necessary. |

|

|

|

|

|

Blade contacting table | 1. | Excessive side pressure | 1. | Reduce side pressure. |

insert. |

| when cutting. |

|

|

| 2. | Table improperly adjusted. | 2. | Adjust table. |

Excessive vibration. | 1. | Wheels not coplanar. | 1. | Adjust wheels coplanar. |

| 2. | Tires incorrectly installed. | 2. | |

| 3. | Bent or worn out blade. | 3. | Replace blade. |

| 4. | Wheels out of balance. | 4. | Replace wheels. |

|

|

|

|

|

Burn marks on the edge | 1. | Too much side pressure | 1. | Feed workpiece straight into the blade. |

of the cut. |

| when feeding workpiece. |

|

|

2.Blade too wide for size of 2. Install a smaller width blade, and/or increase blade

radius being cut. | tension. |

G1019 14'' Bandsaw |