Exhaust Venting |

|

|

|

| Important Notes and Warnings |

This heater is designed to exhaust the products of combus- | • This heater is certified to be installed using Schedule 40 | ||||

tion (flue gases) to the outdoors using a sealed piping sys- | PVC or CPVC plastic vent material. In Canada some | ||||

tem. Table 2 lists the allowable vent materials and sizing | jurisdictions require that this material is approved to | ||||

information. Figure 8 shows the general venting layout while | ULC S636. ULC S636 mandates that components from | ||||

Figures | different systems must not be mixed in the same vent | ||||

clearances. Connection of the venting piping to the blower | runs. Check local codes to determine which materials | ||||

is shown in Figures |

|

|

|

| are allowed in your area and only use approved materi- |

|

|

|

|

| al. All venting material and components must be joined |

Correct installation of the venting system is essential to the | with the approved primer/cleaner and solvent cement. | ||||

safe and efficient operation of this water heater. Vent piping | • Do not common vent this heater with any other appli- | ||||

must be installed in accordance with all applicable local and | ance. | ||||

provincial or state codes. In the absence of such codes, all | • During operation the plastic piping will expand as it | ||||

installation shall meet the requirements as stated in the lat- | heats up and contract as it cools down. This is normal | ||||

est edition of the "Natural Gas and Propane Installation | for this type of venting. Rigidly fastening the vent piping | ||||

Codes" | can cause undue stress that may result in the cracking | ||||

Gas Code" ANSI Z223.1 (NFPA 54) (U.S.A.). | or fracturing the vent piping material. A fracture of the | ||||

|

|

|

|

| venting pipe poses a serious safety hazard. To prevent |

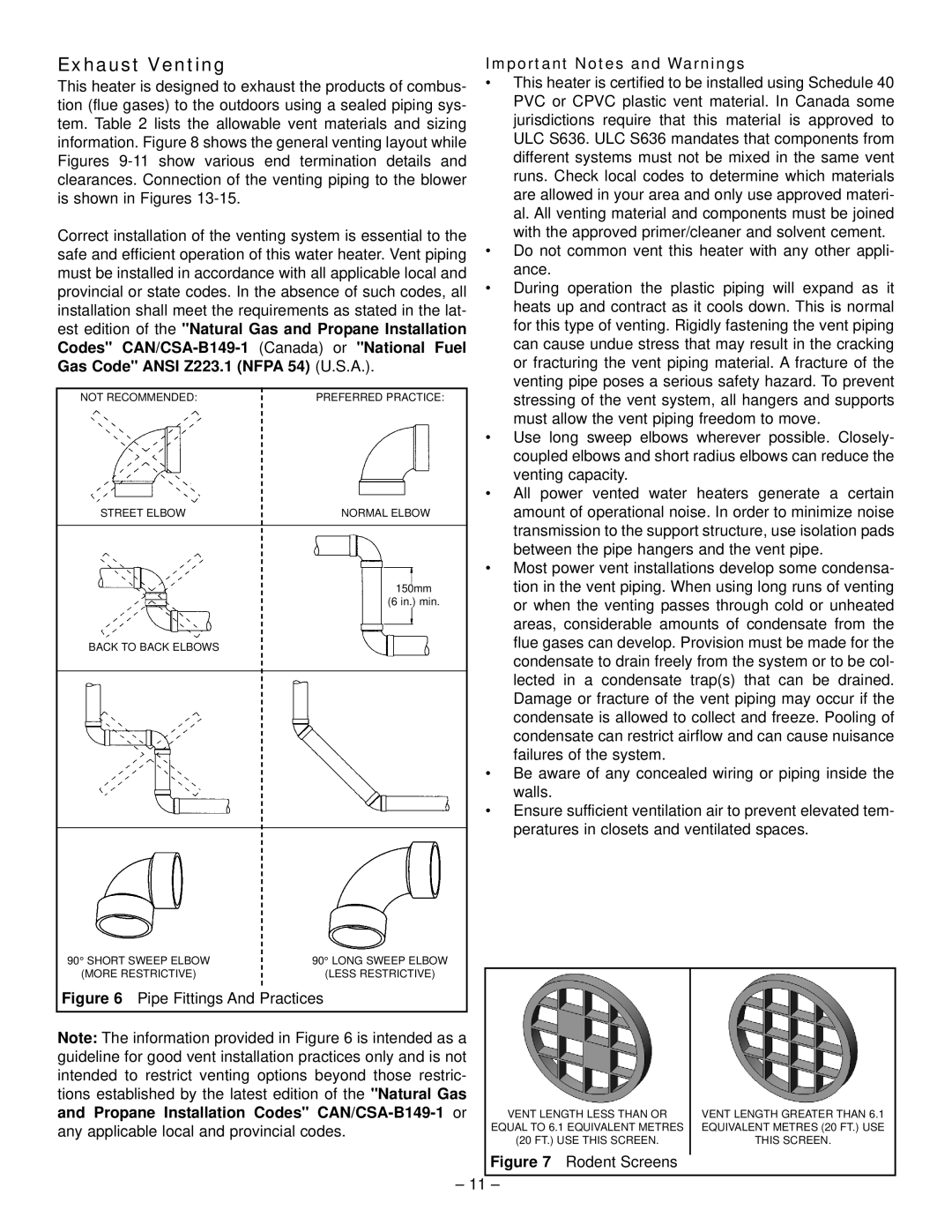

NOT RECOMMENDED: |

| PREFERRED PRACTICE: | stressing of the vent system, all hangers and supports | ||

|

|

|

|

| must allow the vent piping freedom to move. |

|

|

|

|

| • Use long sweep elbows wherever possible. Closely- |

|

|

|

|

| coupled elbows and short radius elbows can reduce the |

|

|

|

|

| venting capacity. |

|

|

|

|

| • All power vented water heaters generate a certain |

STREET ELBOW |

| NORMAL ELBOW | amount of operational noise. In order to minimize noise | ||

|

|

|

|

| transmission to the support structure, use isolation pads |

|

|

|

|

| |

|

|

|

|

| between the pipe hangers and the vent pipe. |

|

|

|

|

| • Most power vent installations develop some condensa- |

|

|

|

|

| tion in the vent piping. When using long runs of venting |

|

|

| 150mm | ||

|

|

| (6 in.) min. |

| or when the venting passes through cold or unheated |

|

|

|

| ||

|

|

|

|

| areas, considerable amounts of condensate from the |

BACK TO BACK ELBOWS |

|

|

|

| flue gases can develop. Provision must be made for the |

|

|

|

|

| condensate to drain freely from the system or to be col- |

|

|

|

|

| lected in a condensate trap(s) that can be drained. |

|

|

|

|

| Damage or fracture of the vent piping may occur if the |

|

|

|

|

| condensate is allowed to collect and freeze. Pooling of |

|

|

|

|

| condensate can restrict airflow and can cause nuisance |

|

|

|

|

| failures of the system. |

|

|

|

|

| • Be aware of any concealed wiring or piping inside the |

|

|

|

|

| walls. |

|

|

|

|

| • Ensure sufficient ventilation air to prevent elevated tem- |

|

|

|

|

| peratures in closets and ventilated spaces. |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

90° SHORT SWEEP ELBOW | 90° LONG SWEEP ELBOW |

|

|

|

|

|

|

|

| |||||

| (MORE RESTRICTIVE) |

|

| (LESS RESTRICTIVE) |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |||||

Figure 6 Pipe Fittings And Practices |

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Note: The information provided in Figure 6 is intended as a |

|

|

|

|

|

|

|

| ||||||

guideline for good vent installation practices only and is not |

|

|

|

|

|

|

|

| ||||||

intended to restrict venting options beyond those restric- |

|

|

|

|

|

|

|

| ||||||

tions established by the latest edition of the "Natural Gas |

|

|

|

|

|

|

|

| ||||||

and Propane Installation Codes" | VENT LENGTH LESS THAN OR |

|

|

| ||||||||||

| VENT LENGTH GREATER THAN 6.1 | |||||||||||||

any applicable local and provincial codes. | EQUAL TO 6.1 EQUIVALENT METRES |

| EQUIVALENT METRES (20 FT.) USE |

| ||||||||||

|

|

|

|

|

|

| (20 FT.) USE THIS SCREEN. |

|

| THIS SCREEN. |

| |||

|

|

|

|

| – 11 | Figure 7 Rodent Screens |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

| – |

|

|

|

|

| ||||