Venting System and Blower

![]() WARNING

WARNING

Keep the area around the heater clear and unobstructed.

Inspect the venting system periodically (minimum twice annually) to make certain that the vent passageways, vent terminal and blower assembly are free and unobstructed. Ensure that any condensate is draining freely. Clean as nec- essary.

•Inspect the vent piping, elbows and connections for signs of stress cracking or deterioration. Make certain the venting is free to move and that all pipe hangers and isolation supports are properly positioned and securely attached. Replace any broken components and rectify any installation problems.

•Particles, especially lint, can clog the vent blower wheel. This can be problematic, especially where con- densation is present, as particles may adhere to the venting surfaces. These conditions can result in nui- sance failures. In areas that have a high level of air- borne particulate (e.g. lint, sawdust, process smoke, laundry areas, etc.) inspection and cleaning may need to be done more frequently. Clean the blower wheel and venting as required to ensure proper performance.

•Inspect the flue collector area for signs of corrosion. This can be an indication of contaminated air, a wet environment, poor burner set up, or high levels of con- densation occurring at the flue collector. Determine and correct any poor operating conditions.

|

|

|

|

|

|

|

|

|

|

| DRAFT | ||

| AIR PRESSURE |

|

| |||

|

| DIVERTER |

| |||

| TUBING |

|

| |||

|

|

|

|

| ||

|

|

| AIR INTAKE | |||

|

|

|

|

| ||

| MOTOR |

|

| OPENING FOR | ||

VENTILATION |

|

| DRAFT DIVERTER | |||

| OPENINGS |

|

|

|

| |

|

|

|

|

|

| |

BLOWER

MOTOR

L I M I T

SWITCH

LIMIT

SWITCH

WIRES

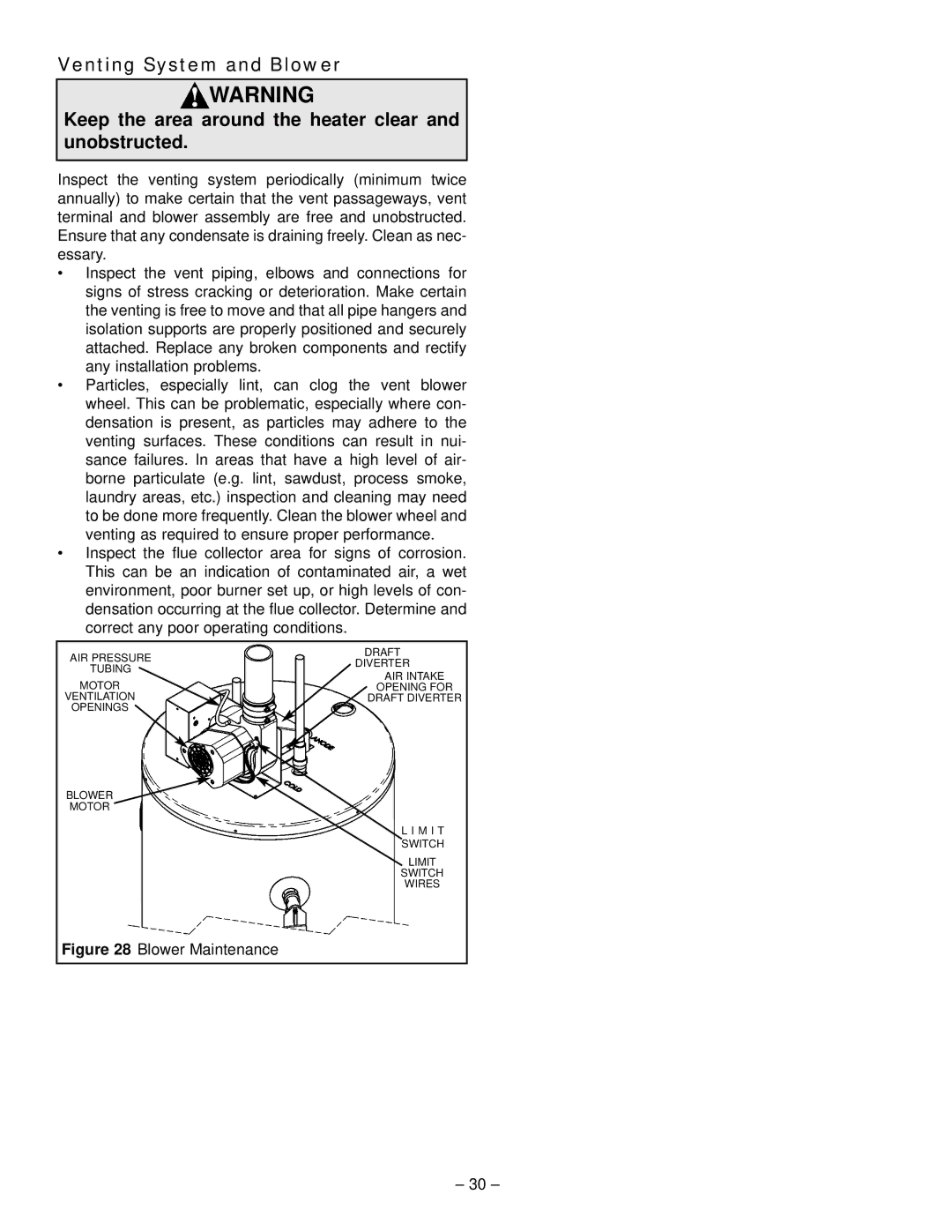

Figure 28 Blower Maintenance

– 30 –