Troubleshooting

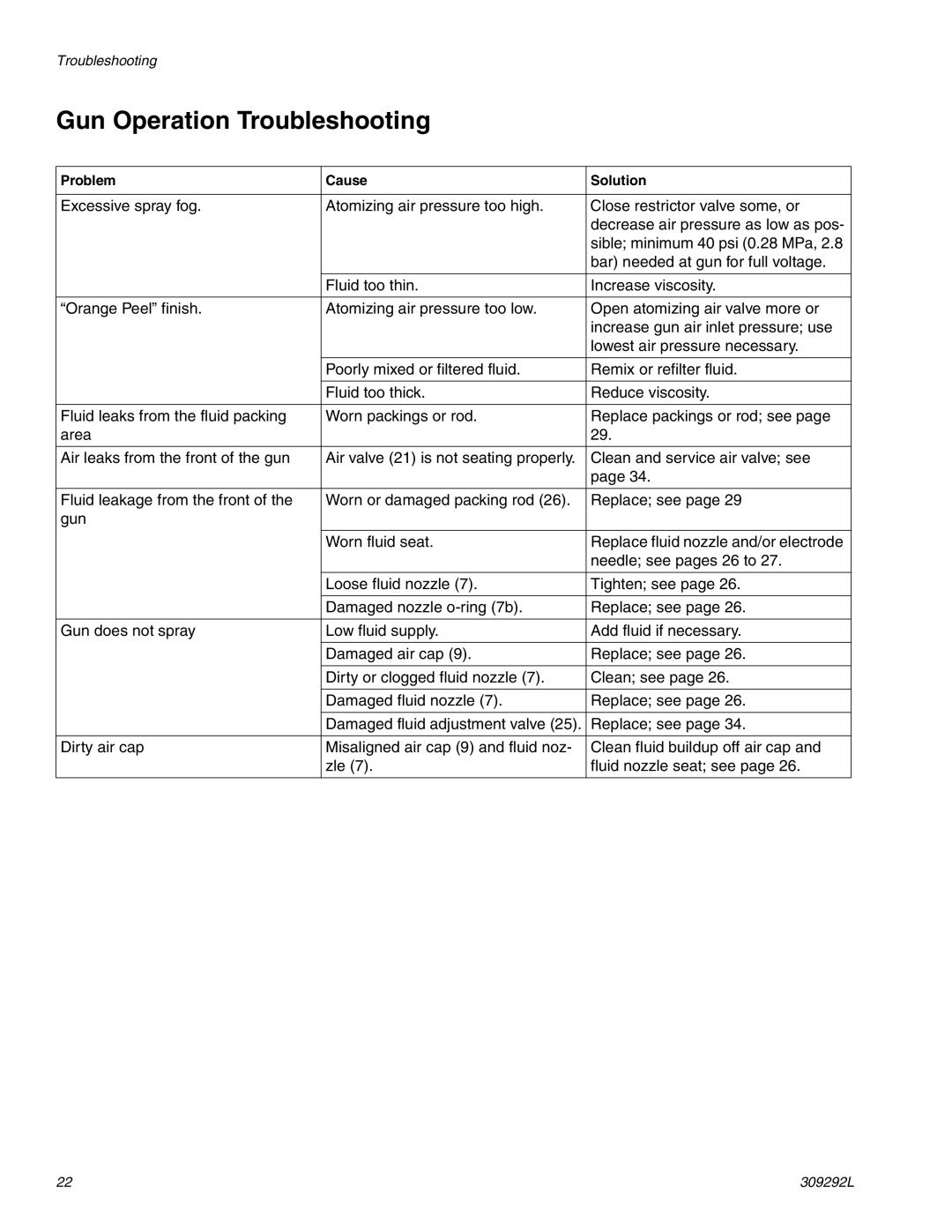

Gun Operation Troubleshooting

Problem | Cause | Solution |

|

|

|

Excessive spray fog. | Atomizing air pressure too high. | Close restrictor valve some, or |

|

| decrease air pressure as low as pos- |

|

| sible; minimum 40 psi (0.28 MPa, 2.8 |

|

| bar) needed at gun for full voltage. |

|

|

|

| Fluid too thin. | Increase viscosity. |

|

|

|

“Orange Peel” finish. | Atomizing air pressure too low. | Open atomizing air valve more or |

|

| increase gun air inlet pressure; use |

|

| lowest air pressure necessary. |

|

|

|

| Poorly mixed or filtered fluid. | Remix or refilter fluid. |

|

|

|

| Fluid too thick. | Reduce viscosity. |

|

|

|

Fluid leaks from the fluid packing | Worn packings or rod. | Replace packings or rod; see page |

area |

| 29. |

|

|

|

Air leaks from the front of the gun | Air valve (21) is not seating properly. | Clean and service air valve; see |

|

| page 34. |

|

|

|

Fluid leakage from the front of the | Worn or damaged packing rod (26). | Replace; see page 29 |

gun |

|

|

|

|

|

| Worn fluid seat. | Replace fluid nozzle and/or electrode |

|

| needle; see pages 26 to 27. |

|

|

|

| Loose fluid nozzle (7). | Tighten; see page 26. |

|

|

|

| Damaged nozzle | Replace; see page 26. |

|

|

|

Gun does not spray | Low fluid supply. | Add fluid if necessary. |

|

|

|

| Damaged air cap (9). | Replace; see page 26. |

|

|

|

| Dirty or clogged fluid nozzle (7). | Clean; see page 26. |

|

|

|

| Damaged fluid nozzle (7). | Replace; see page 26. |

|

|

|

| Damaged fluid adjustment valve (25). | Replace; see page 34. |

|

|

|

Dirty air cap | Misaligned air cap (9) and fluid noz- | Clean fluid buildup off air cap and |

| zle (7). | fluid nozzle seat; see page 26. |

|

|

|

22 | 309292L |