Gas Supply Line

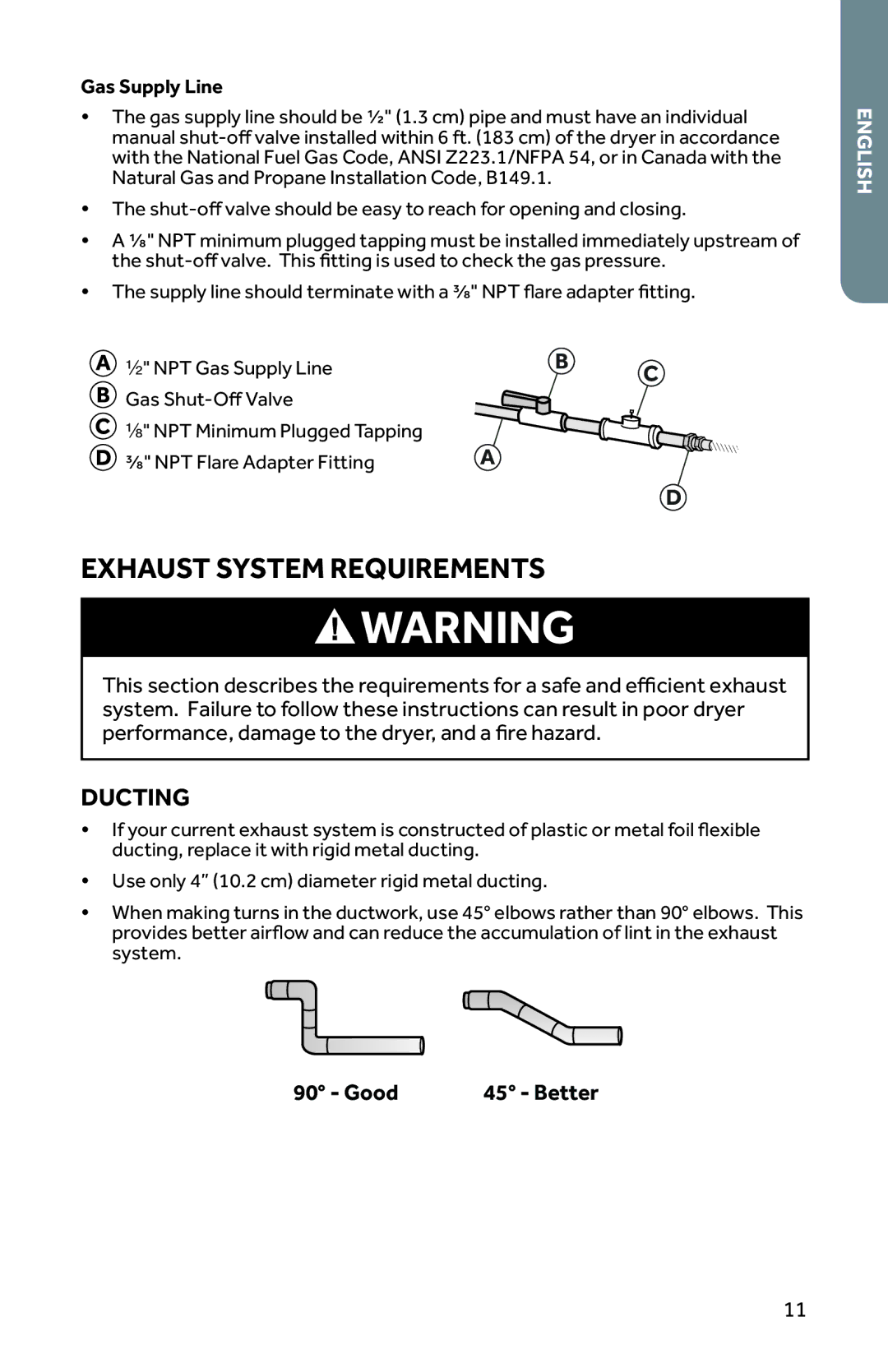

•The gas supply line should be ½" (1.3 cm) pipe and must have an individual manual

•The

•A "" NPT minimum plugged tapping must be installed immediately upstream of the

•The supply line should terminate with a !" NPT ßare adapter Þtting.

![]() ¹⁄₂" NPT Gas Supply Line

¹⁄₂" NPT Gas Supply Line

![]() Gas

Gas

![]() ¹⁄₈" NPT Minimum Plugged Tapping

¹⁄₈" NPT Minimum Plugged Tapping ![]() !" NPT Flare Adapter Fitting

!" NPT Flare Adapter Fitting

B C

A

D

EXHAUST SYSTEM REQUIREMENTS

![]() WARNING

WARNING

This section describes the requirements for a safe and efficient exhaust system. Failure to follow these instructions can result in poor dryer performance, damage to the dryer, and a e hazard.

DUCTING

•If your current exhaust system is constructed of plastic or metal foil ßexible ducting, replace it with rigid metal ducting.

•Use only 4” (10.2 cm) diameter rigid metal ducting.

•When making turns in the ductwork, use 45° elbows rather than 90° elbows. This provides better airßow and can reduce the accumulation of lint in the exhaust system.

90° - Good 45° - Better

11