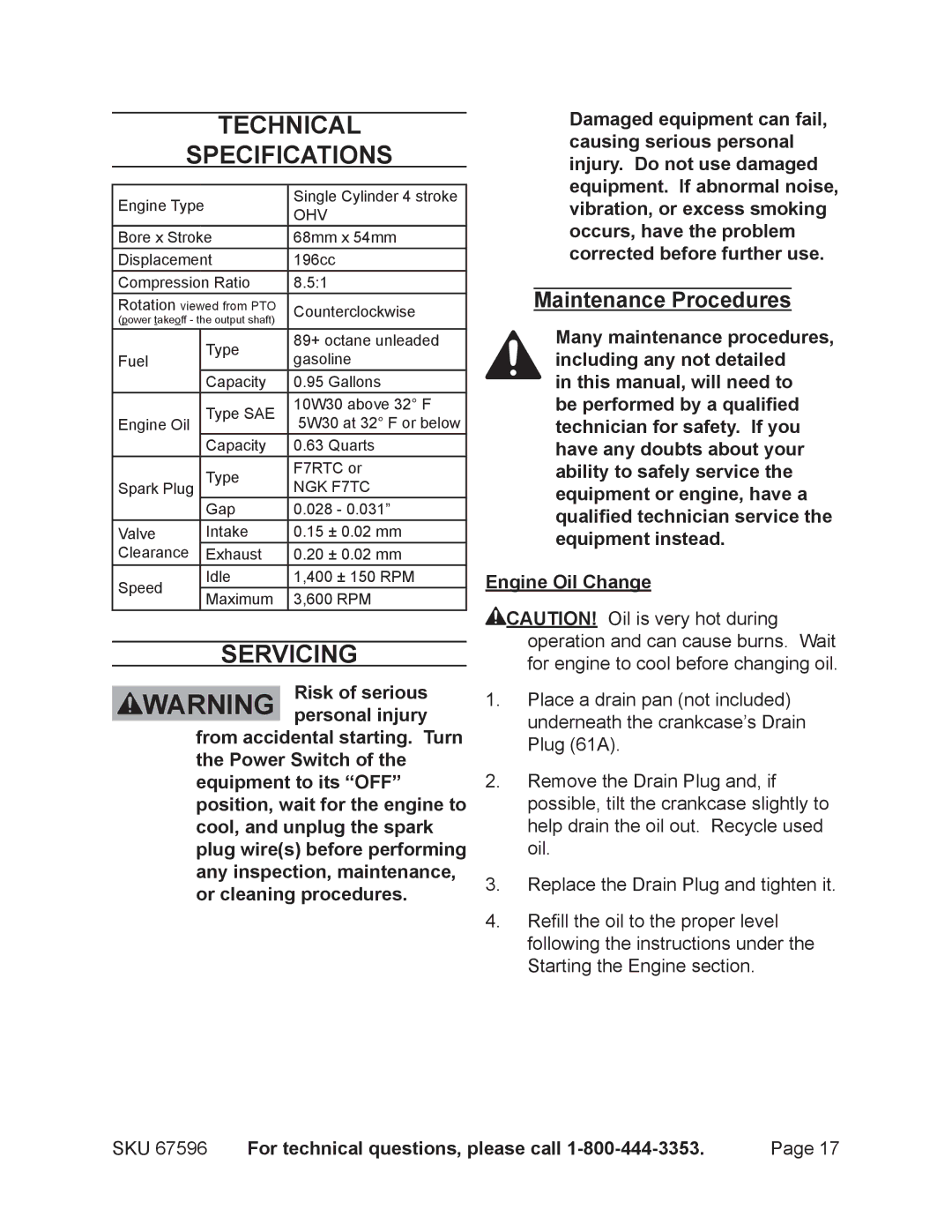

Technical

Specifications

Engine Type |

| Single Cylinder 4 stroke | ||

| OHV | |||

|

|

| ||

Bore x Stroke | 68mm x 54mm | |||

Displacement | 196cc | |||

Compression Ratio | 8.5:1 | |||

Rotation viewed from PTO | Counterclockwise | |||

(power takeoff - the output shaft) | ||||

| ||||

|

| Type | 89+ octane unleaded | |

Fuel |

| gasoline | ||

|

| |||

|

| Capacity | 0.95 Gallons | |

|

| Type SAE | 10W30 above 32° F | |

Engine Oil |

| 5W30 at 32° F or below | ||

|

| Capacity | 0.63 Quarts | |

|

| Type | F7RTC or | |

Spark Plug |

| NGK F7TC | ||

|

| Gap | 0.028 - 0.031” | |

Valve |

| Intake | 0.15 ± 0.02 mm | |

Clearance |

| Exhaust | 0.20 ± 0.02 mm | |

Speed |

| Idle | 1,400 ± 150 RPM | |

| Maximum | 3,600 RPM | ||

|

| |||

Servicing

WARNING Risk of serious personal injury

from accidental starting. Turn the Power Switch of the equipment to its “OFF” position, wait for the engine to cool, and unplug the spark plug wire(s) before performing any inspection, maintenance, or cleaning procedures.

Damaged equipment can fail, causing serious personal injury. Do not use damaged equipment. If abnormal noise, vibration, or excess smoking occurs, have the problem corrected before further use.

Maintenance Procedures

Many maintenance procedures, including any not detailed

in this manual, will need to be performed by a qualified technician for safety. If you have any doubts about your ability to safely service the equipment or engine, have a qualified technician service the equipment instead.

Engine Oil Change

![]() CAUTION! Oil is very hot during operation and can cause burns. Wait for engine to cool before changing oil.

CAUTION! Oil is very hot during operation and can cause burns. Wait for engine to cool before changing oil.

1.Place a drain pan (not included) underneath the crankcase’s Drain Plug (61A).

2.Remove the Drain Plug and, if possible, tilt the crankcase slightly to help drain the oil out. Recycle used oil.

3.Replace the Drain Plug and tighten it.

4.Refill the oil to the proper level following the instructions under the Starting the Engine section.

SKU 67596 | For technical questions, please call | Page 17 |