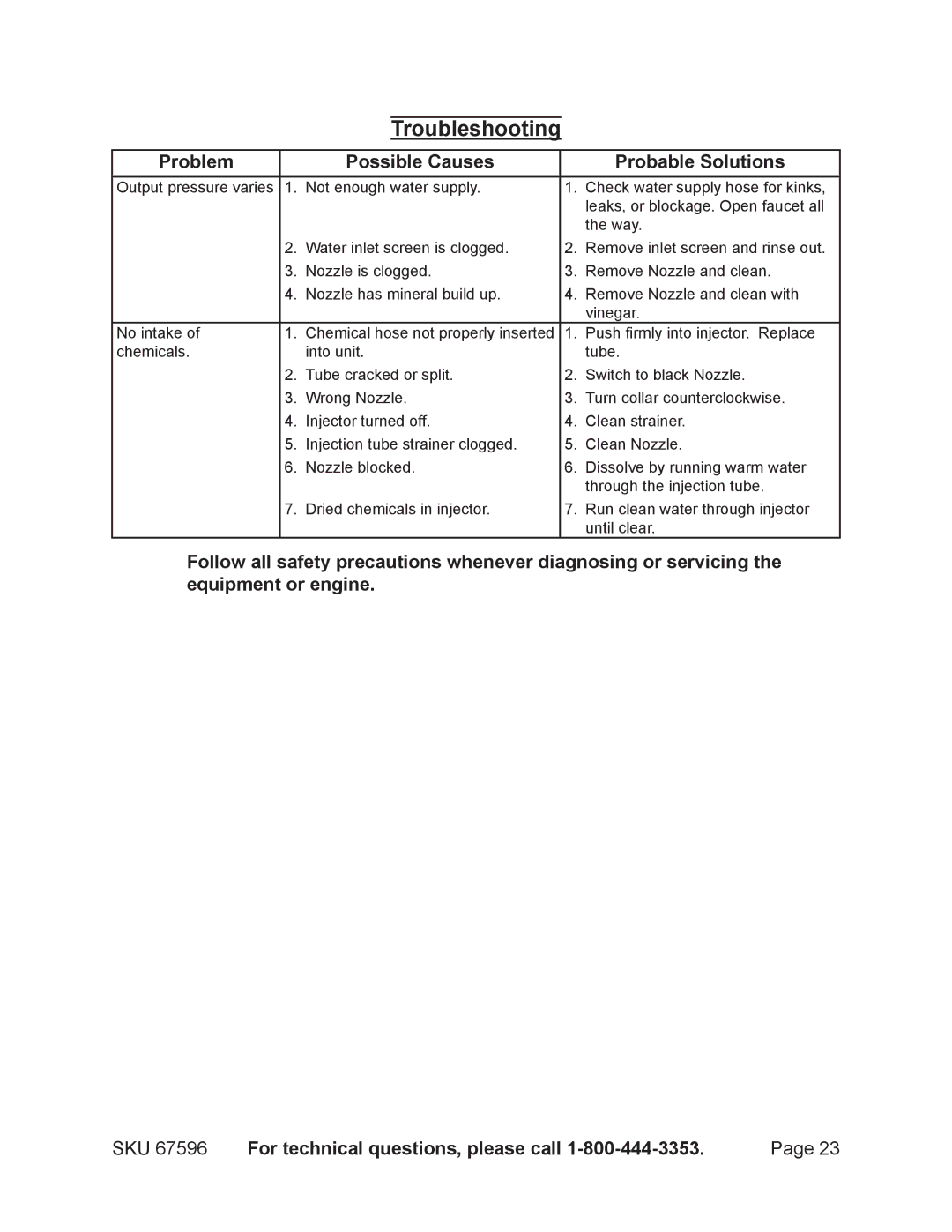

Troubleshooting

Problem |

| Possible Causes |

| Probable Solutions |

Output pressure varies | 1. Not enough water supply. | 1. | Check water supply hose for kinks, | |

|

|

|

| leaks, or blockage. Open faucet all |

|

|

|

| the way. |

| 2. | Water inlet screen is clogged. | 2. | Remove inlet screen and rinse out. |

| 3. | Nozzle is clogged. | 3. | Remove Nozzle and clean. |

| 4. | Nozzle has mineral build up. | 4. | Remove Nozzle and clean with |

|

|

|

| vinegar. |

No intake of | 1. Chemical hose not properly inserted | 1. | Push firmly into injector. Replace | |

chemicals. |

| into unit. |

| tube. |

| 2. | Tube cracked or split. | 2. | Switch to black Nozzle. |

| 3. | Wrong Nozzle. | 3. | Turn collar counterclockwise. |

| 4. | Injector turned off. | 4. | Clean strainer. |

| 5. | Injection tube strainer clogged. | 5. | Clean Nozzle. |

| 6. | Nozzle blocked. | 6. | Dissolve by running warm water |

|

|

|

| through the injection tube. |

| 7. | Dried chemicals in injector. | 7. | Run clean water through injector |

|

|

|

| until clear. |

Follow all safety precautions whenever diagnosing or servicing the equipment or engine.

SKU 67596 | For technical questions, please call | Page 23 |