Model 67596

Model 67596  PRESSURE WASHER Easy

PRESSURE WASHER Easy Start-up guide

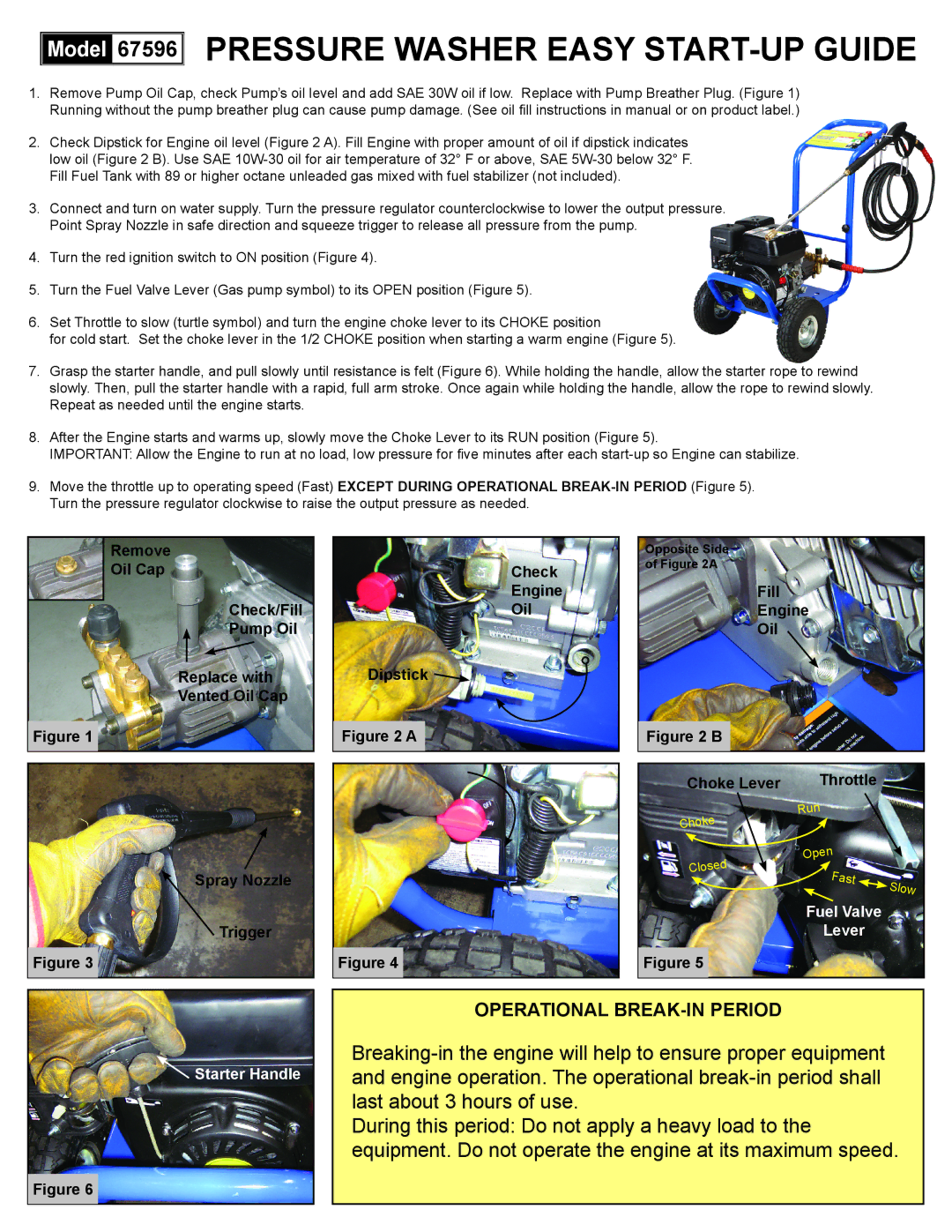

1.Remove Pump Oil Cap, check Pump’s oil level and add SAE 30W oil if low. Replace with Pump Breather Plug. (Figure 1)

Running without the pump breather plug can cause pump damage. (See oil fill instructions in manual or on product label.)

2.Check Dipstick for Engine oil level (Figure 2 A). Fill Engine with proper amount of oil if dipstick indicates low oil (Figure 2 B). Use SAE

3.Connect and turn on water supply. Turn the pressure regulator counterclockwise to lower the output pressure. Point Spray Nozzle in safe direction and squeeze trigger to release all pressure from the pump.

4.Turn the red ignition switch to ON position (Figure 4).

5.Turn the Fuel Valve Lever (Gas pump symbol) to its OPEN position (Figure 5).

6.Set Throttle to slow (turtle symbol) and turn the engine choke lever to its CHOKE position

for cold start. Set the choke lever in the 1/2 CHOKE position when starting a warm engine (Figure 5).

7.Grasp the starter handle, and pull slowly until resistance is felt (Figure 6). While holding the handle, allow the starter rope to rewind slowly. Then, pull the starter handle with a rapid, full arm stroke. Once again while holding the handle, allow the rope to rewind slowly. Repeat as needed until the engine starts.

8.After the Engine starts and warms up, slowly move the Choke Lever to its RUN position (Figure 5).

IMPORTANT: Allow the Engine to run at no load, low pressure for five minutes after each

9.Move the throttle up to operating speed (Fast) except during OPERATIONAL

Remove

Oil Cap

Check/Fill

Pump Oil

Replace with

Vented Oil Cap

Figure 1

Check

Engine

Oil

Dipstick ![]()

Figure 2 A

Opposite Side

of Figure 2A

Fill

Engine

Oil

Figure 2 B

Choke Lever | Throttle |

Spray Nozzle

Trigger

Figure 3

Figure 4

Choke

Closed

Figure 5

Run

Open

Fast | Slow |

|

Fuel Valve

Lever

![]() Starter Handle

Starter Handle

Figure 6

OPERATIONAL Break-in Period

During this period: Do not apply a heavy load to the equipment. Do not operate the engine at its maximum speed.