Step 3. Installing the Flue System

A. Flue System Approvals

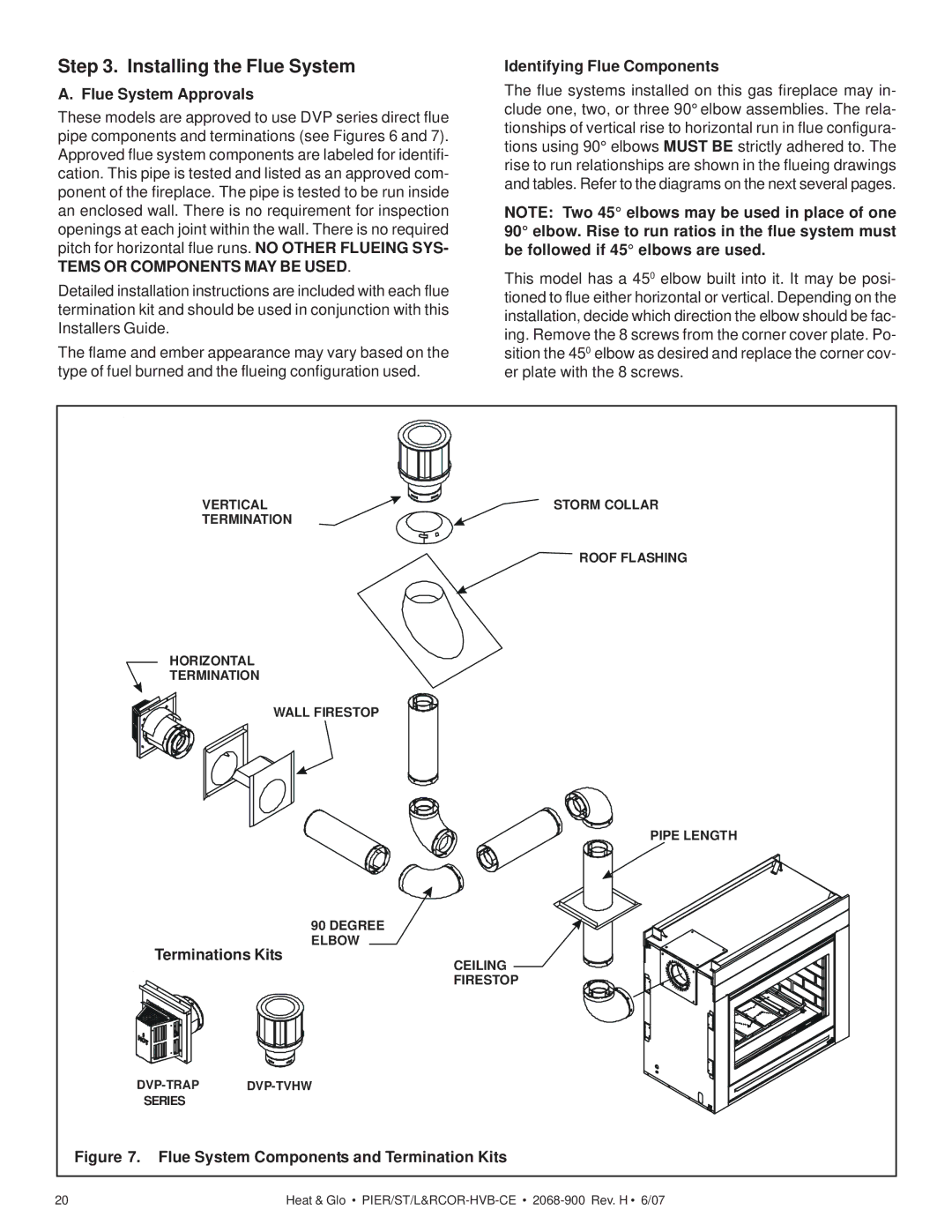

These models are approved to use DVP series direct flue pipe components and terminations (see Figures 6 and 7). Approved flue system components are labeled for identifi- cation. This pipe is tested and listed as an approved com- ponent of the fireplace. The pipe is tested to be run inside an enclosed wall. There is no requirement for inspection openings at each joint within the wall. There is no required pitch for horizontal flue runs. NO OTHER FLUEING SYS-

TEMS OR COMPONENTS MAY BE USED.

Detailed installation instructions are included with each flue termination kit and should be used in conjunction with this Installers Guide.

The flame and ember appearance may vary based on the type of fuel burned and the flueing configuration used.

Identifying Flue Components

The flue systems installed on this gas fireplace may in- clude one, two, or three 90° elbow assemblies. The rela- tionships of vertical rise to horizontal run in flue configura- tions using 90° elbows MUST BE strictly adhered to. The rise to run relationships are shown in the flueing drawings and tables. Refer to the diagrams on the next several pages.

NOTE: Two 45° elbows may be used in place of one 90° elbow. Rise to run ratios in the flue system must be followed if 45° elbows are used.

This model has a 450 elbow built into it. It may be posi- tioned to flue either horizontal or vertical. Depending on the installation, decide which direction the elbow should be fac- ing. Remove the 8 screws from the corner cover plate. Po- sition the 450 elbow as desired and replace the corner cov- er plate with the 8 screws.

| VERTICAL |

| STORM COLLAR |

| TERMINATION |

|

|

|

|

| ROOF FLASHING |

HORIZONTAL |

|

| |

TERMINATION |

|

| |

| WALL FIRESTOP |

|

|

|

|

| PIPE LENGTH |

| 90 DEGREE |

|

|

| ELBOW |

|

|

Terminations Kits | CEILING |

| |

|

|

| |

|

| FIRESTOP |

|

|

| ||

SERIES |

|

|

|

Figure 7. Flue System Components and Termination Kits |

| ||

20 | Heat & Glo • | ||