English

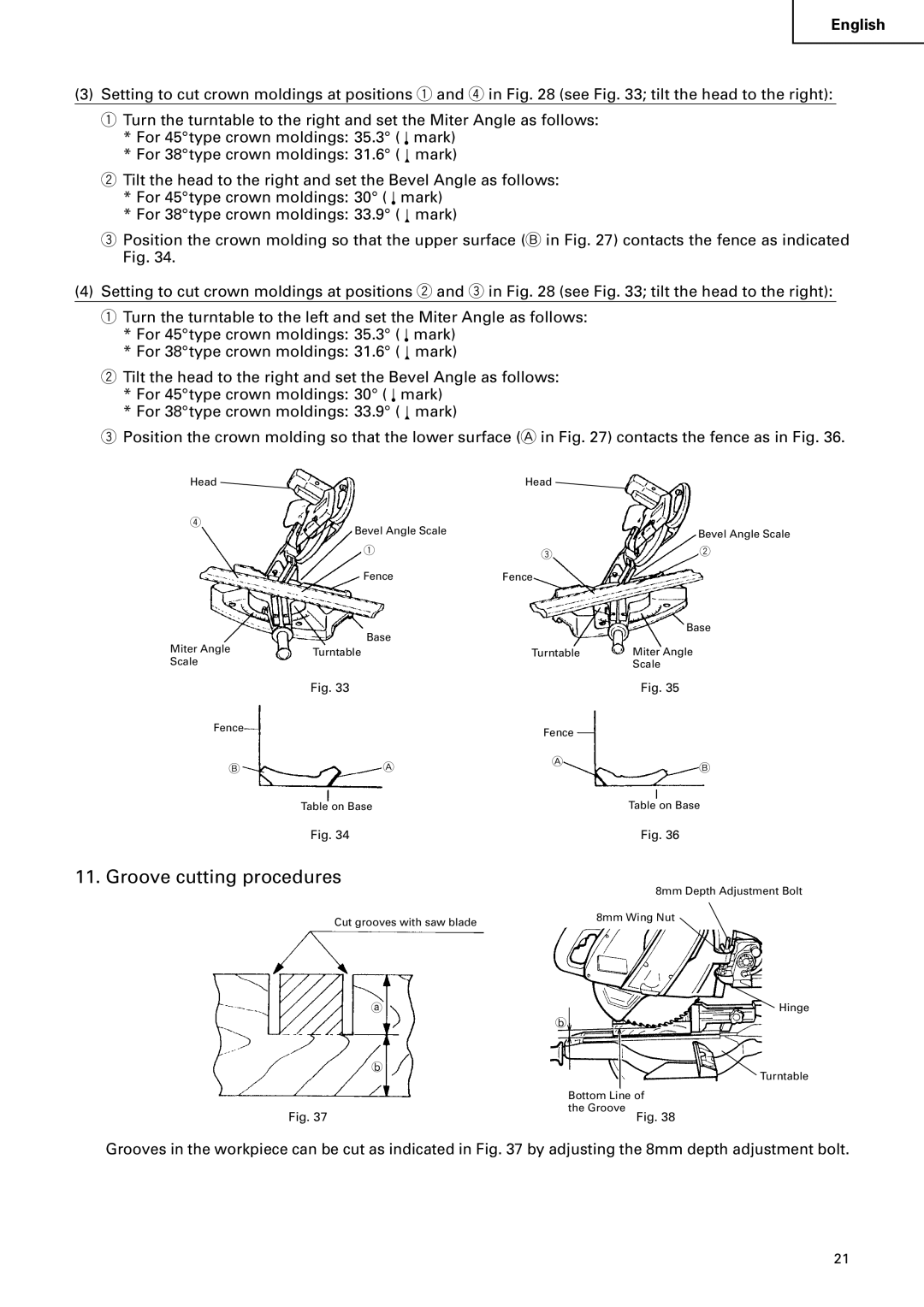

(3)Setting to cut crown moldings at positions q and r in Fig. 28 (see Fig. 33; tilt the head to the right): q Turn the turntable to the right and set the Miter Angle as follows:

* For 45°type crown moldings: 35.3° ( |

| mark) |

* For 38°type crown moldings: 31.6° ( |

| mark) |

|

wTilt the head to the right and set the Bevel Angle as follows:

* For 45°type crown moldings: 30° ( |

| mark) | |

* For 38°type crown moldings: 33.9° ( |

| mark) | |

| |||

ePosition the crown molding so that the upper surface (B in Fig. 27) contacts the fence as indicated Fig. 34.

(4)Setting to cut crown moldings at positions w and e in Fig. 28 (see Fig. 33; tilt the head to the right): q Turn the turntable to the left and set the Miter Angle as follows:

*For 45°type crown moldings: 35.3° ( mark)

* For 38°type crown moldings: 31.6° ( mark)

wTilt the head to the right and set the Bevel Angle as follows:

* For 45°type crown moldings: 30° ( |

| mark) | |

* For 38°type crown moldings: 33.9° ( |

| mark) | |

| |||

ePosition the crown molding so that the lower surface (A in Fig. 27) contacts the fence as in Fig. 36.

Head |

| Head |

|

r | Bevel Angle Scale |

|

|

|

| Bevel Angle Scale | |

|

|

| |

| q | e | w |

|

|

| |

| Fence | Fence |

|

| Base |

| Base |

Miter Angle |

|

| |

Turntable | Turntable | Miter Angle | |

Scale |

|

| Scale |

| Fig. 33 |

| Fig. 35 |

Fence |

| Fence |

|

|

|

| |

B | A | A | B |

| |||

| Table on Base |

| Table on Base |

| Fig. 34 |

| Fig. 36 |

11. Groove cutting procedures

| 8mm Depth Adjustment Bolt |

Cut grooves with saw blade | 8mm Wing Nut |

| |

a | Hinge |

| b |

b | Turntable |

| |

| Bottom Line of |

Fig. 37 | the Groove |

Fig. 38 |

Grooves in the workpiece can be cut as indicated in Fig. 37 by adjusting the 8mm depth adjustment bolt.

21