English

Accordingly, press the handle down gently and carefully.

*In slide cutting, gently push the handle back (rearwards) in a single, smooth opera- tion.

Stopping the handle movement during the cut will cause unwanted cutting marks on the workpiece.

![]() WARNING: * For slide cutting, follow the procedures indicated above in Fig. 21.

WARNING: * For slide cutting, follow the procedures indicated above in Fig. 21.

Forward slide cutting (toward the operator) is very dangerous because the saw blade could kick upward from the workpiece. Therefore, always slide the handle away from the operator.

*Always return the carriage to the full rear position after each crosscut operation in order to reduce the risk of injury.

*Never put your hand on the side handle during the cutting operation because the saw blade comes close to the side handle when the motor head is lowered.

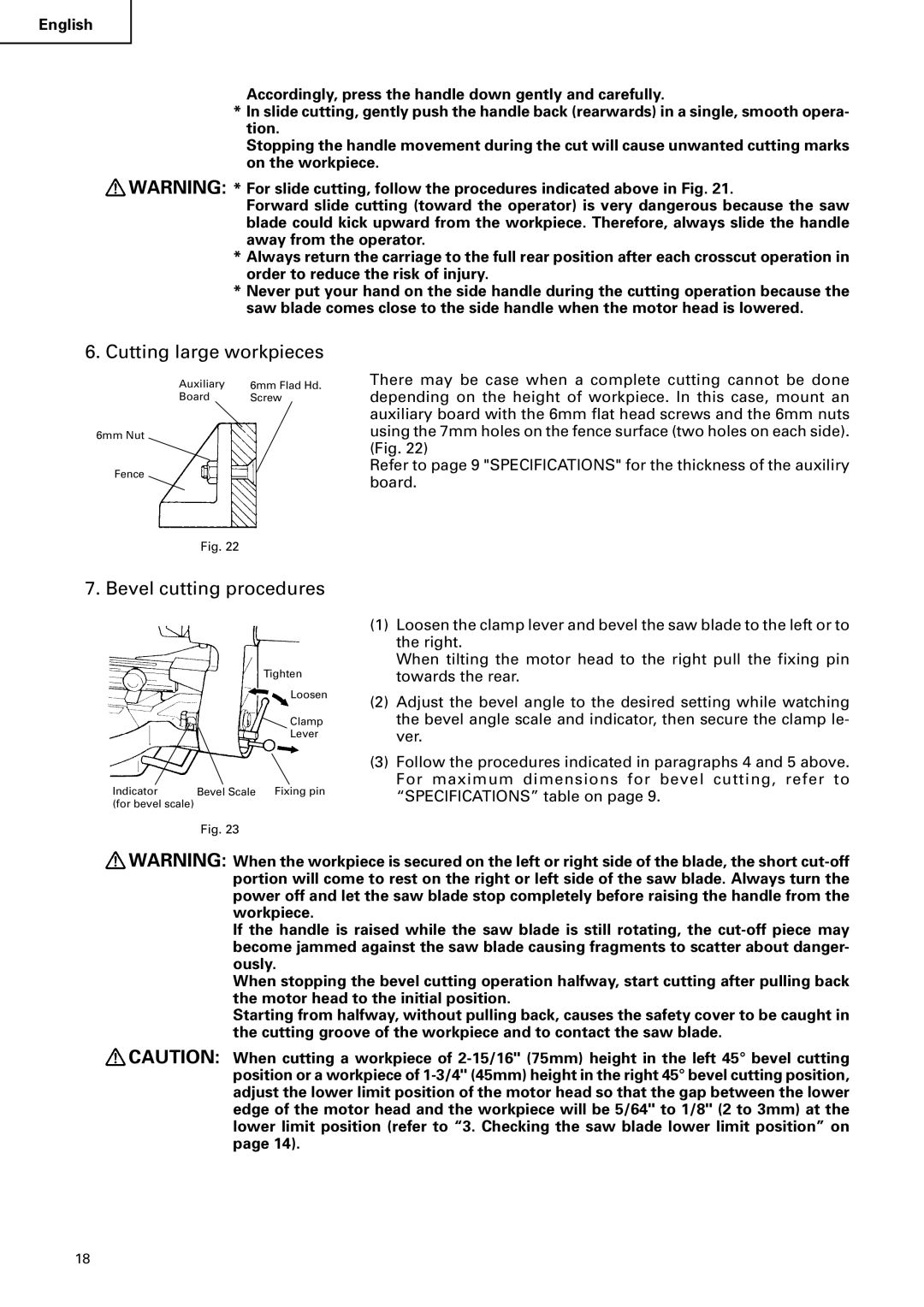

6. Cutting large workpieces

Auxiliary | 6mm Flad Hd. |

Board | Screw |

6mm Nut

Fence

Fig. 22

There may be case when a complete cutting cannot be done depending on the height of workpiece. In this case, mount an auxiliary board with the 6mm flat head screws and the 6mm nuts using the 7mm holes on the fence surface (two holes on each side). (Fig. 22)

Refer to page 9 "SPECIFICATIONS" for the thickness of the auxiliry board.

7. Bevel cutting procedures

Tighten

Loosen

Clamp

Lever

Indicator | Bevel Scale | Fixing pin |

(for bevel scale) |

|

|

Fig. 23

(1)Loosen the clamp lever and bevel the saw blade to the left or to the right.

When tilting the motor head to the right pull the fixing pin towards the rear.

(2)Adjust the bevel angle to the desired setting while watching the bevel angle scale and indicator, then secure the clamp le- ver.

(3)Follow the procedures indicated in paragraphs 4 and 5 above. For maximum dimensions for bevel cutting, refer to “SPECIFICATIONS” table on page 9.

![]() WARNING: When the workpiece is secured on the left or right side of the blade, the short

WARNING: When the workpiece is secured on the left or right side of the blade, the short

If the handle is raised while the saw blade is still rotating, the

When stopping the bevel cutting operation halfway, start cutting after pulling back the motor head to the initial position.

Starting from halfway, without pulling back, causes the safety cover to be caught in the cutting groove of the workpiece and to contact the saw blade.

![]() CAUTION: When cutting a workpiece of

CAUTION: When cutting a workpiece of

18