English

1. Switch operation

Handle

Hole

Trigger

Switch

Fig. 17

The trigger switch

The trigger switch will not operate unless the

When the trigger switch is released, the power goes off and the

![]() WARNING: Always remove the

WARNING: Always remove the

2. Using the Vise Assembly (Standard accessory)

| Screw Holder |

6mm | Knob |

Knob Bolt |

|

Vise Shaft | Vise |

V Shape | Plate |

| |

Groove |

|

Fence |

|

8mm Knob Bolt | Workpiece |

Fig. 18

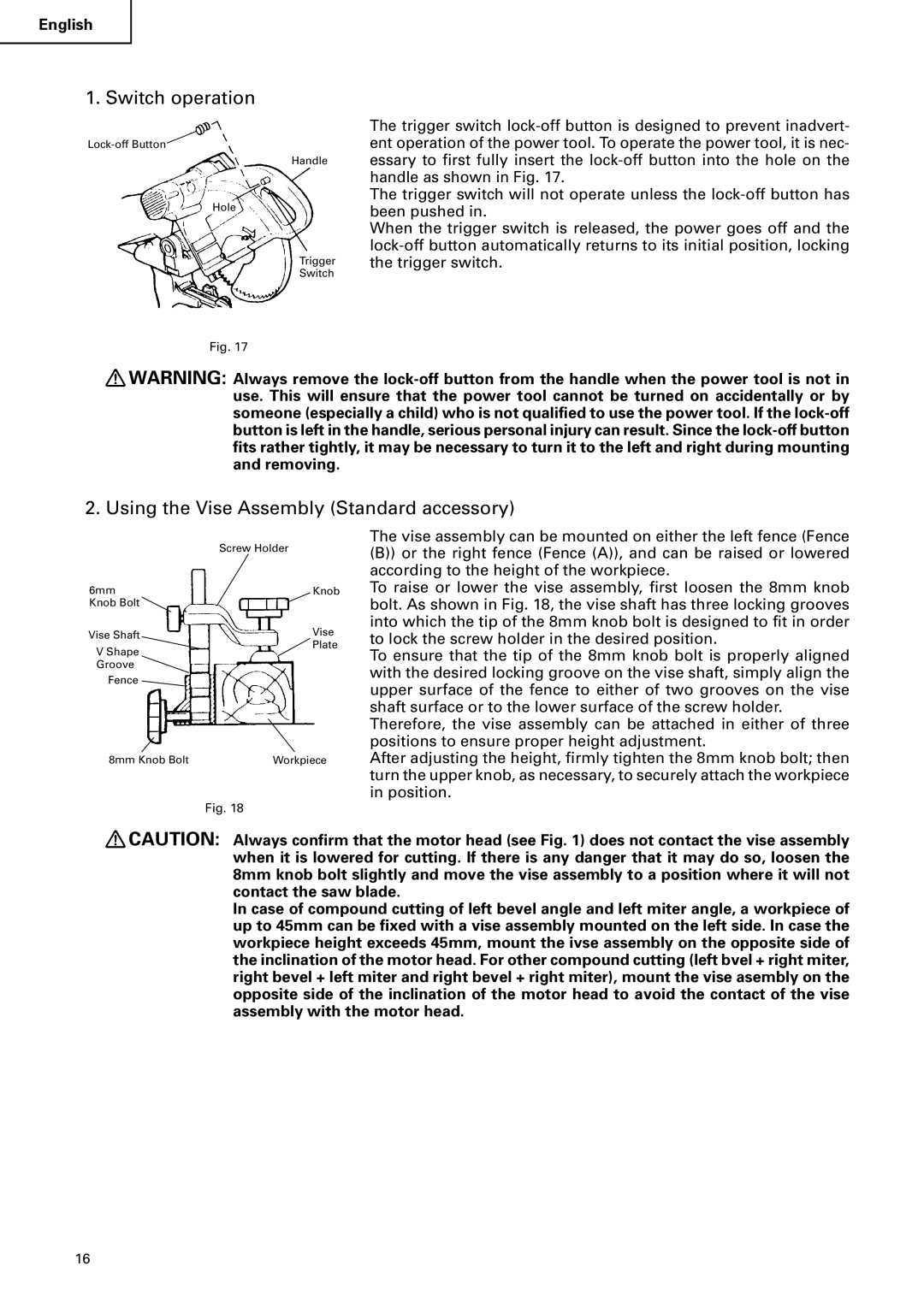

The vise assembly can be mounted on either the left fence (Fence (B)) or the right fence (Fence (A)), and can be raised or lowered according to the height of the workpiece.

To raise or lower the vise assembly, first loosen the 8mm knob bolt. As shown in Fig. 18, the vise shaft has three locking grooves into which the tip of the 8mm knob bolt is designed to fit in order to lock the screw holder in the desired position.

To ensure that the tip of the 8mm knob bolt is properly aligned with the desired locking groove on the vise shaft, simply align the upper surface of the fence to either of two grooves on the vise shaft surface or to the lower surface of the screw holder.

Therefore, the vise assembly can be attached in either of three positions to ensure proper height adjustment.

After adjusting the height, firmly tighten the 8mm knob bolt; then turn the upper knob, as necessary, to securely attach the workpiece in position.

![]() CAUTION: Always confirm that the motor head (see Fig. 1) does not contact the vise assembly when it is lowered for cutting. If there is any danger that it may do so, loosen the 8mm knob bolt slightly and move the vise assembly to a position where it will not contact the saw blade.

CAUTION: Always confirm that the motor head (see Fig. 1) does not contact the vise assembly when it is lowered for cutting. If there is any danger that it may do so, loosen the 8mm knob bolt slightly and move the vise assembly to a position where it will not contact the saw blade.

In case of compound cutting of left bevel angle and left miter angle, a workpiece of up to 45mm can be fixed with a vise assembly mounted on the left side. In case the workpiece height exceeds 45mm, mount the ivse assembly on the opposite side of the inclination of the motor head. For other compound cutting (left bvel + right miter, right bevel + left miter and right bevel + right miter), mount the vise asembly on the opposite side of the inclination of the motor head to avoid the contact of the vise assembly with the motor head.

16