English

BEFORE CUTTING

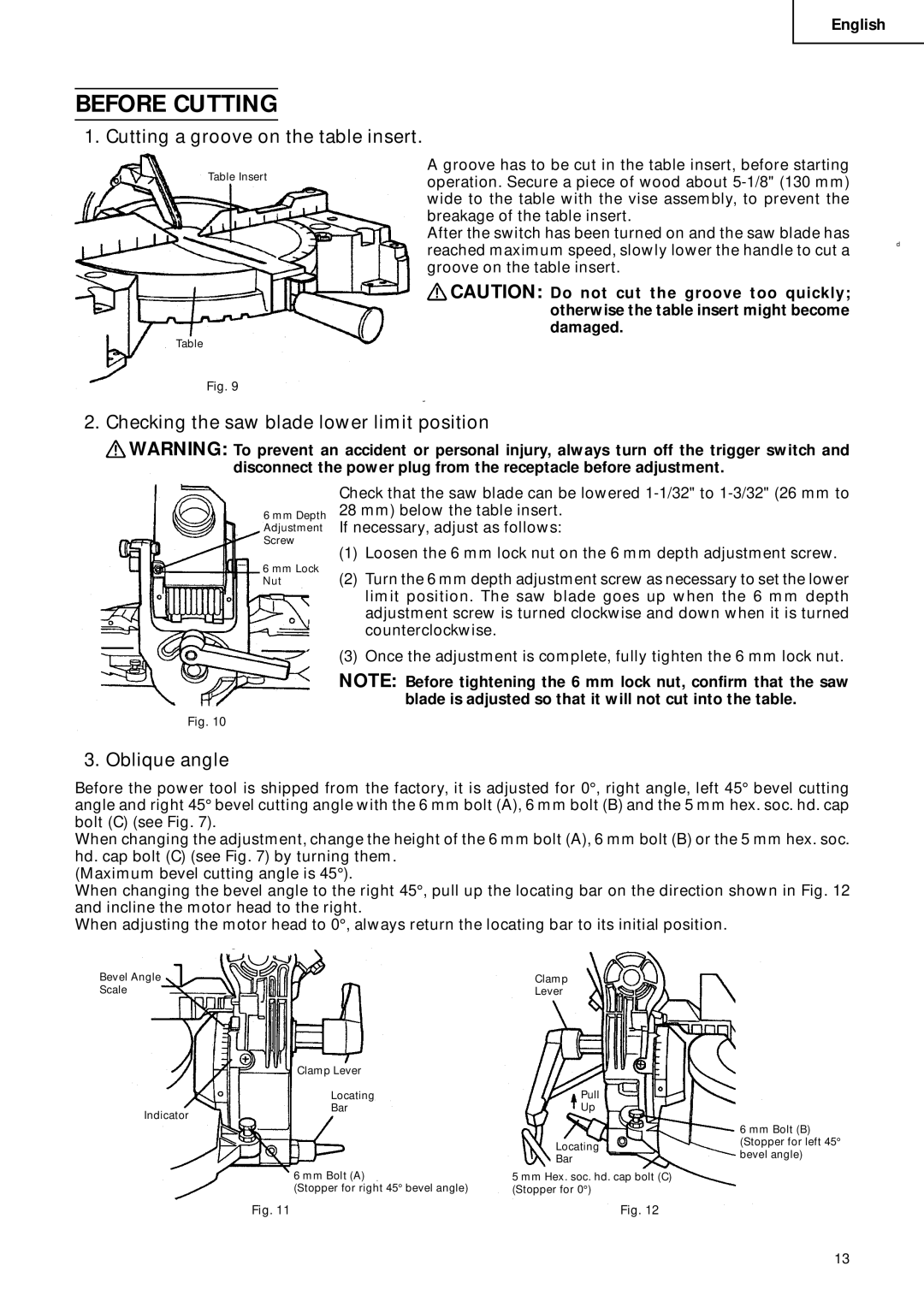

1. Cutting a groove on the table insert.

Table Insert

Table

Fig. 9

A groove has to be cut in the table insert, before starting operation. Secure a piece of wood about

After the switch has been turned on and the saw blade has reached maximum speed, slowly lower the handle to cut a groove on the table insert.

![]() CAUTION: Do not cut the groove too quickly; otherwise the table insert might become damaged.

CAUTION: Do not cut the groove too quickly; otherwise the table insert might become damaged.

d

2. Checking the saw blade lower limit position

WARNING: To prevent an accident or personal injury, always turn off the trigger switch and disconnect the power plug from the receptacle before adjustment.

6 mm Depth Adjustment Screw

6 mm Lock Nut

Fig. 10

Check that the saw blade can be lowered

If necessary, adjust as follows:

(1)Loosen the 6 mm lock nut on the 6 mm depth adjustment screw.

(2)Turn the 6 mm depth adjustment screw as necessary to set the lower limit position. The saw blade goes up when the 6 mm depth adjustment screw is turned clockwise and down when it is turned counterclockwise.

(3)Once the adjustment is complete, fully tighten the 6 mm lock nut.

NOTE: Before tightening the 6 mm lock nut, confirm that the saw blade is adjusted so that it will not cut into the table.

3. Oblique angle

Before the power tool is shipped from the factory, it is adjusted for 0°, right angle, left 45° bevel cutting angle and right 45° bevel cutting angle with the 6 mm bolt (A), 6 mm bolt (B) and the 5 mm hex. soc. hd. cap bolt (C) (see Fig. 7).

When changing the adjustment, change the height of the 6 mm bolt (A), 6 mm bolt (B) or the 5 mm hex. soc. hd. cap bolt (C) (see Fig. 7) by turning them.

(Maximum bevel cutting angle is 45°).

When changing the bevel angle to the right 45°, pull up the locating bar on the direction shown in Fig. 12 and incline the motor head to the right.

When adjusting the motor head to 0°, always return the locating bar to its initial position.

Bevel Angle

Scale

Clamp Lever

Clamp Lever

Indicator

Locating Bar

Pull

Up

Locating Bar

6 mm Bolt (B) (Stopper for left 45° bevel angle)

6 mm Bolt (A)

(Stopper for right 45° bevel angle)

Fig. 11

5 mm Hex. soc. hd. cap bolt (C) (Stopper for 0°)

Fig. 12

13