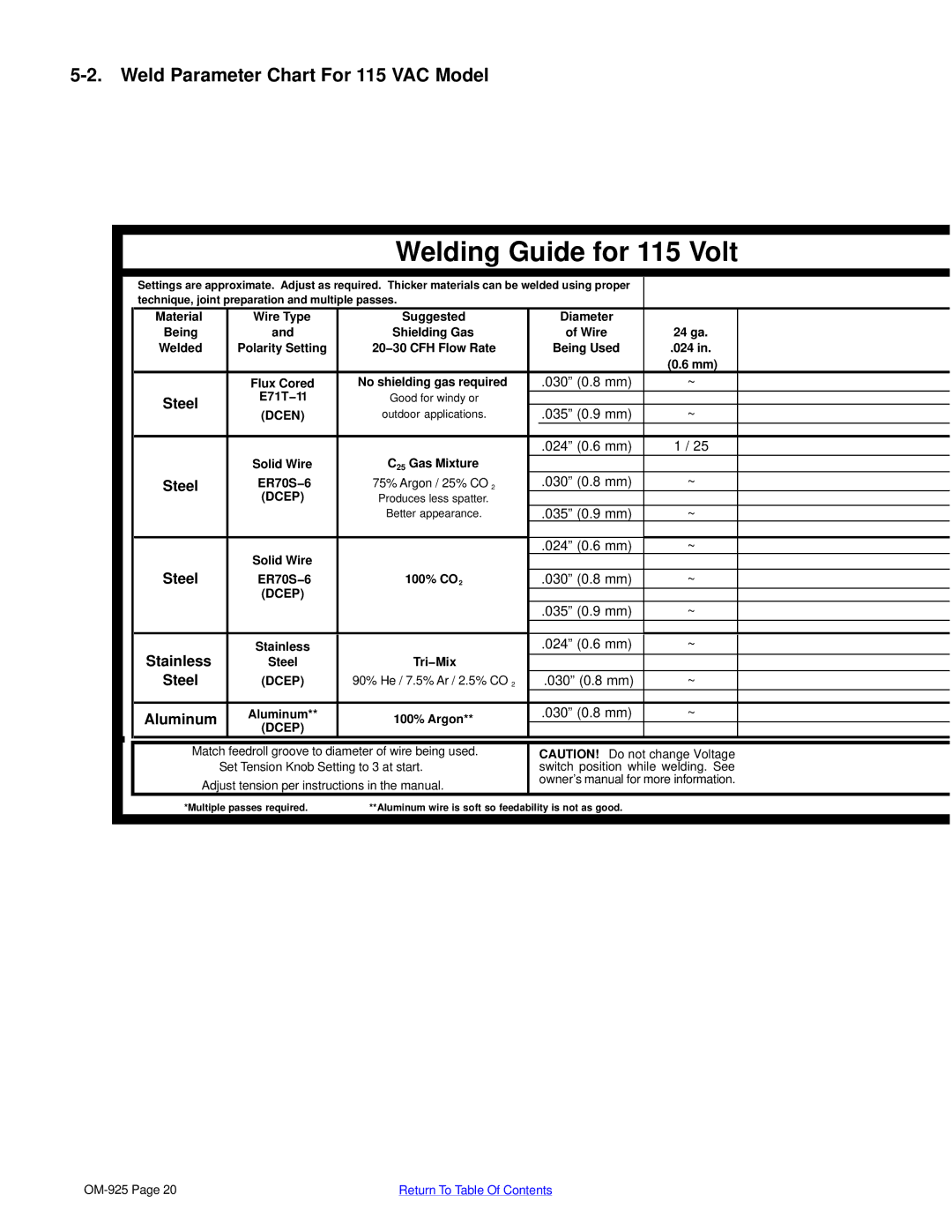

5-2. Weld Parameter Chart For 115 VAC Model

Welding Guide for 115 Volt

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Settings are approximate. Adjust as required. Thicker materials can be welded using proper |

|

| |||||

|

|

|

| technique, joint preparation and multiple passes. |

|

|

|

| |||

|

|

|

| Material | Wire Type |

| Suggested |

| Diameter |

|

|

|

|

|

| Being | and |

| Shielding Gas |

| of Wire | 24 ga. |

|

|

|

|

| Welded | Polarity Setting | 20−30 CFH Flow Rate |

| Being Used | .024 in. |

| |

|

|

|

|

|

|

|

|

|

| (0.6 mm) |

|

|

|

|

|

| Flux Cored | No shielding gas required |

| .030” (0.8 mm) | ~ |

| |

|

|

|

| Steel | E71T−11 |

| Good for windy or |

|

|

|

|

|

|

|

| (DCEN) |

| outdoor applications. |

| .035” (0.9 mm) | ~ |

| |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .024” (0.6 mm) | 1 / 25 |

|

|

|

|

|

| Solid Wire |

| C25 Gas Mixture |

|

|

|

|

|

|

|

| Steel | ER70S−6 | 75% Argon / 25% CO 2 |

| .030” (0.8 mm) | ~ |

| |

|

|

|

|

| (DCEP) |

| Produces less spatter. |

|

|

|

|

|

|

|

|

|

|

| Better appearance. |

| .035” (0.9 mm) | ~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Solid Wire |

|

|

| .024” (0.6 mm) | ~ |

|

|

|

|

| Steel |

|

|

|

|

|

| |

|

|

|

| ER70S−6 |

| 100% CO2 |

| .030” (0.8 mm) | ~ |

| |

|

|

|

|

| (DCEP) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .035” (0.9 mm) | ~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Stainless | Stainless |

|

|

| .024” (0.6 mm) | ~ |

|

|

|

|

| Steel |

| Tri−Mix |

|

|

|

| |

|

|

|

| Steel | (DCEP) | 90% He / 7.5% Ar / 2.5% CO 2 |

| .030” (0.8 mm) | ~ |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Aluminum | Aluminum** |

| 100% Argon** |

| .030” (0.8 mm) | ~ |

|

|

|

|

| (DCEP) |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

Match feedroll groove to diameter of wire being used. Set Tension Knob Setting to 3 at start.

Adjust tension per instructions in the manual.

CAUTION! Do not change Voltage switch position while welding. See owner’s manual for more information.

*Multiple passes required. | **Aluminum wire is soft so feedability is not as good. |

|

|

Return To Table Of Contents |