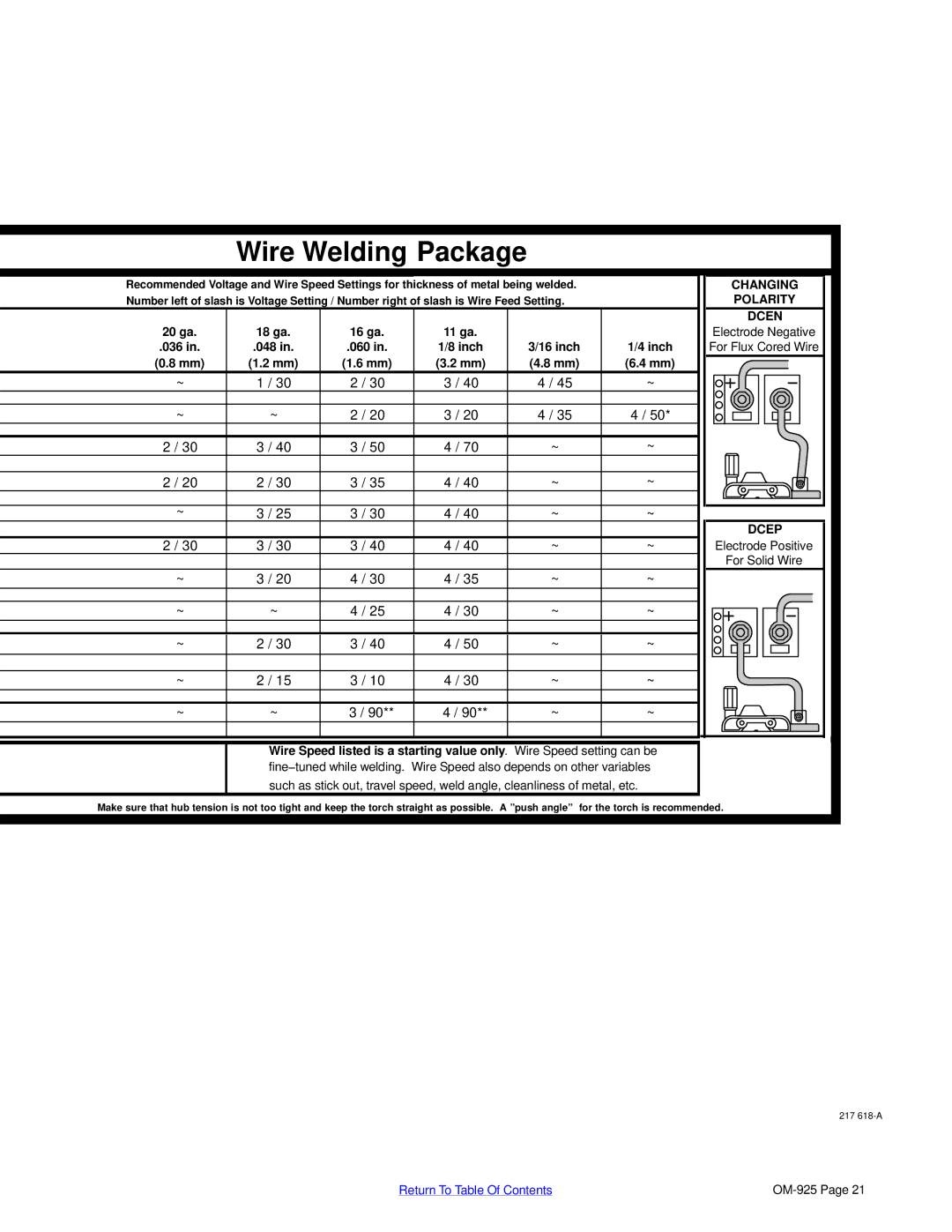

Wire Welding Package

Recommended Voltage and Wire Speed Settings for thickness of metal being welded.

Number left of slash is Voltage Setting / Number right of slash is Wire Feed Setting.

20 ga. | 18 ga. | 16 ga. | 11 ga. |

|

|

.036 in. | .048 in. | .060 in. | 1/8 inch | 3/16 inch | 1/4 inch |

(0.8 mm) | (1.2 mm) | (1.6 mm) | (3.2 mm) | (4.8 mm) | (6.4 mm) |

~ | 1 / 30 | 2 / 30 | 3 / 40 | 4 / 45 | ~ |

|

|

|

|

|

|

~ | ~ | 2 / 20 | 3 / 20 | 4 / 35 | 4 / 50* |

|

|

|

|

|

|

2 / 30 | 3 / 40 | 3 / 50 | 4 / 70 | ~ | ~ |

|

|

|

|

|

|

2 / 20 | 2 / 30 | 3 / 35 | 4 / 40 | ~ | ~ |

|

|

|

|

|

|

~ | 3 / 25 | 3 / 30 | 4 / 40 | ~ | ~ |

|

|

|

|

|

|

2 / 30 | 3 / 30 | 3 / 40 | 4 / 40 | ~ | ~ |

|

|

|

|

|

|

~ | 3 / 20 | 4 / 30 | 4 / 35 | ~ | ~ |

|

|

|

|

|

|

~ | ~ | 4 / 25 | 4 / 30 | ~ | ~ |

|

|

|

|

|

|

~ | 2 / 30 | 3 / 40 | 4 / 50 | ~ | ~ |

|

|

|

|

|

|

|

|

|

|

|

|

~ | 2 / 15 | 3 / 10 | 4 / 30 | ~ | ~ |

|

|

|

|

|

|

~ | ~ | 3 / 90** | 4 / 90** | ~ | ~ |

|

|

|

|

|

|

|

| ||||

| Wire Speed listed is a starting value only. Wire Speed setting can be | ||||

| fine−tuned while welding. Wire Speed also depends on other variables | ||||

| such as stick out, travel speed, weld angle, cleanliness of metal, etc. | ||||

CHANGING

POLARITY

DCEN

Electrode Negative

For Flux Cored Wire

DCEP

Electrode Positive

For Solid Wire

Make sure that hub tension is not too tight and keep the torch straight as possible. A ”push angle” for the torch is recommen ded.

217

Return To Table Of Contents |