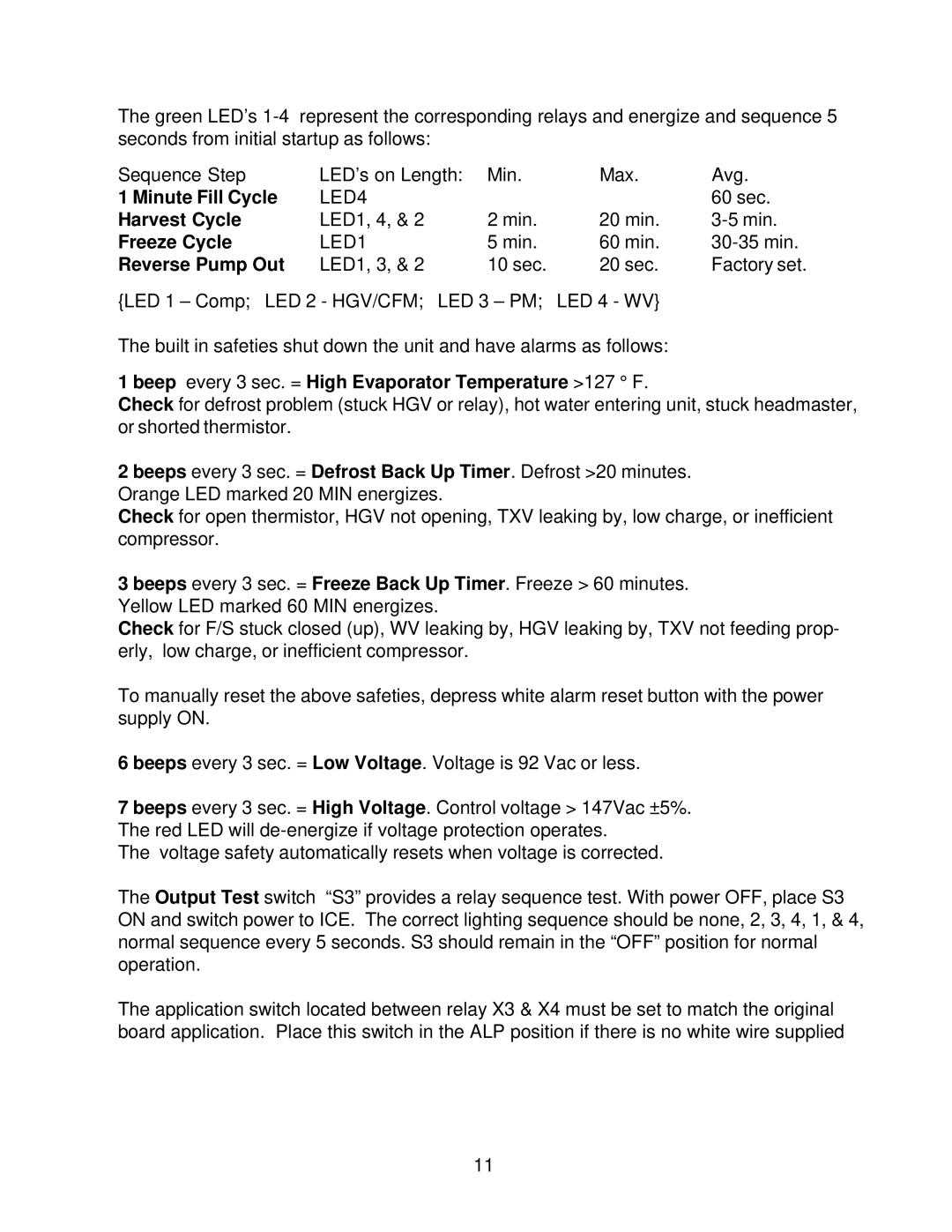

The green LED’s

Sequence Step | LED’s on Length: | Min. | Max. | Avg. |

1 Minute Fill Cycle | LED4 |

|

| 60 sec. |

Harvest Cycle | LED1, 4, & 2 | 2 min. | 20 min. | |

Freeze Cycle | LED1 | 5 min. | 60 min. | |

Reverse Pump Out | LED1, 3, & 2 | 10 sec. | 20 sec. | Factory set. |

{LED 1 – Comp; LED 2 - HGV/CFM; LED 3 – PM; | LED 4 - WV} |

| ||

The built in safeties shut down the unit and have alarms as follows:

1 beep every 3 sec. = High Evaporator Temperature >127 ° F.

Check for defrost problem (stuck HGV or relay), hot water entering unit, stuck headmaster, or shorted thermistor.

2 beeps every 3 sec. = Defrost Back Up Timer. Defrost >20 minutes. Orange LED marked 20 MIN energizes.

Check for open thermistor, HGV not opening, TXV leaking by, low charge, or inefficient compressor.

3 beeps every 3 sec. = Freeze Back Up Timer. Freeze > 60 minutes. Yellow LED marked 60 MIN energizes.

Check for F/S stuck closed (up), WV leaking by, HGV leaking by, TXV not feeding prop- erly, low charge, or inefficient compressor.

To manually reset the above safeties, depress white alarm reset button with the power supply ON.

6 beeps every 3 sec. = Low Voltage. Voltage is 92 Vac or less.

7 beeps every 3 sec. = High Voltage. Control voltage > 147Vac ±5%. The red LED will

The voltage safety automatically resets when voltage is corrected.

The Output Test switch “S3” provides a relay sequence test. With power OFF, place S3 ON and switch power to ICE. The correct lighting sequence should be none, 2, 3, 4, 1, & 4, normal sequence every 5 seconds. S3 should remain in the “OFF” position for normal operation.

The application switch located between relay X3 & X4 must be set to match the original board application. Place this switch in the ALP position if there is no white wire supplied

11