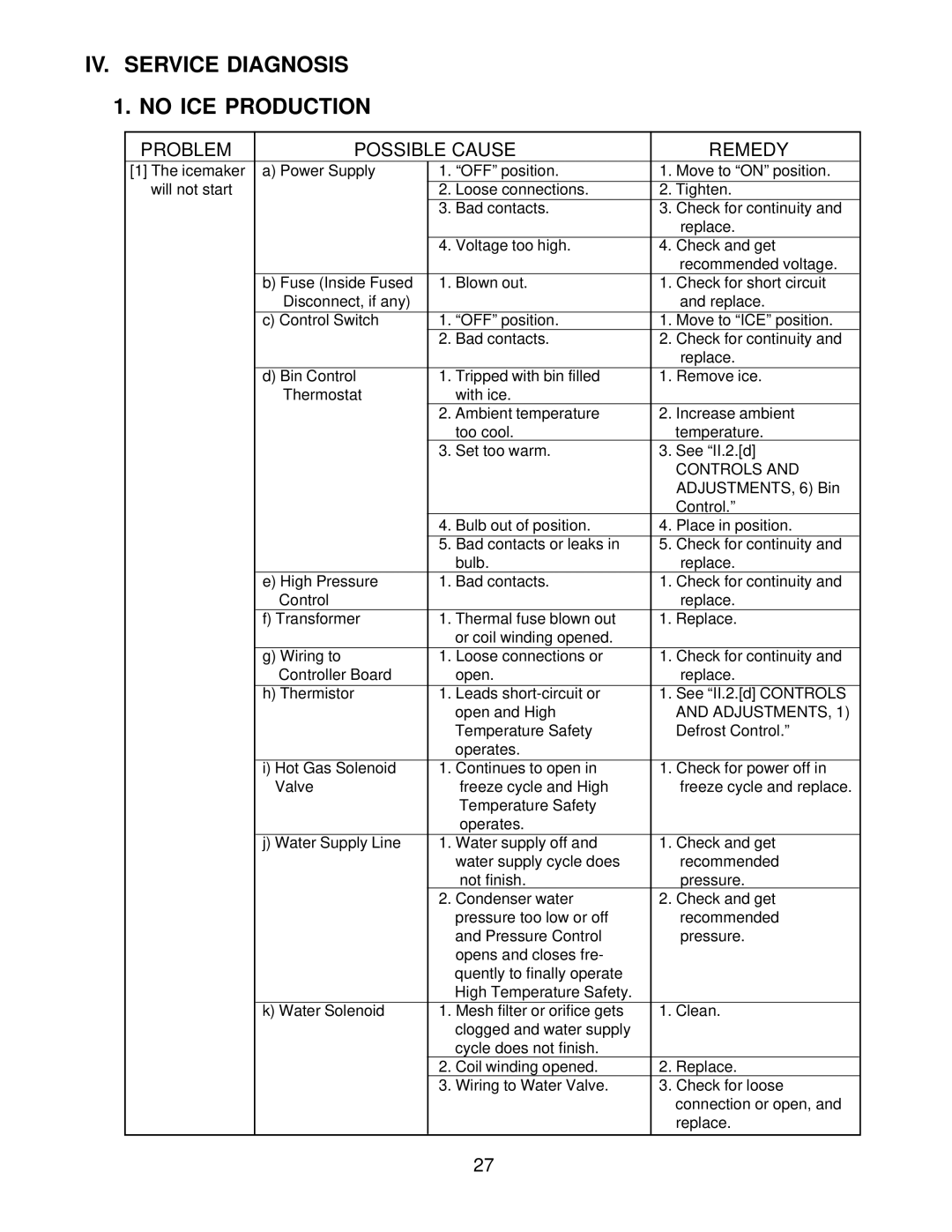

IV. SERVICE DIAGNOSIS

1. NO ICE PRODUCTION

PROBLEM | POSSIBLE CAUSE |

| REMEDY | ||||

[1] The icemaker | a) Power Supply | 1. | “OFF” position. | 1. | Move to “ON” position. |

| |

will not start |

|

| 2. | Loose connections. | 2. | Tighten. |

|

|

|

| 3. | Bad contacts. | 3. | Check for continuity and | |

|

|

|

|

|

| replace. | |

|

|

| 4. | Voltage too high. | 4. | Check and get | |

|

|

|

|

|

| recommended voltage. | |

| b) Fuse (Inside Fused | 1. | Blown out. | 1. | Check for short circuit |

| |

| Disconnect, if any) |

|

|

| and replace. | ||

| c) Control Switch | 1. | “OFF” position. | 1. | Move to “ICE” position. | ||

|

|

| 2. | Bad contacts. | 2. | Check for continuity and |

|

|

|

|

|

|

| replace. | |

| d) Bin Control | 1. | Tripped with bin filled | 1. | Remove ice. | ||

| Thermostat |

| with ice. |

|

|

| |

|

|

| 2. Ambient temperature | 2. Increase ambient |

| ||

|

|

|

| too cool. |

| temperature. | |

|

|

| 3. | Set too warm. | 3. | See “II.2.[d] |

|

|

|

|

|

|

| CONTROLS AND | |

|

|

|

|

|

| ADJUSTMENTS, 6) Bin | |

|

|

|

|

|

| Control.” |

|

|

|

| 4. | Bulb out of position. | 4. | Place in position. | |

|

|

| 5. | Bad contacts or leaks in | 5. | Check for continuity and |

|

|

|

|

| bulb. |

| replace. | |

| e) High Pressure | 1. | Bad contacts. | 1. | Check for continuity and | ||

| Control |

|

|

| replace. | ||

| f) Transformer | 1. | Thermal fuse blown out | 1. Replace. | |||

|

|

|

| or coil winding opened. |

|

|

|

| g) Wiring to | 1. | Loose connections or | 1. | Check for continuity and | ||

| Controller Board |

| open. |

| replace. | ||

| h) Thermistor | 1. | Leads | 1. | See “II.2.[d] CONTROLS | ||

|

|

|

| open and High |

| AND ADJUSTMENTS, 1) | |

|

|

|

| Temperature Safety |

| Defrost Control.” | |

|

|

|

| operates. |

|

|

|

| i) Hot Gas Solenoid | 1. | Continues to open in | 1. Check for power off in | |||

| Valve |

| freeze cycle and High |

| freeze cycle and replace. | ||

|

|

|

| Temperature Safety |

|

|

|

|

|

|

| operates. |

|

|

|

| j) Water Supply Line | 1. | Water supply off and | 1. | Check and get | ||

|

|

|

| water supply cycle does |

| recommended | |

|

|

|

| not finish. |

| pressure. | |

|

|

| 2. Condenser water | 2. | Check and get |

| |

|

|

|

| pressure too low or off |

| recommended | |

|

|

|

| and Pressure Control |

| pressure. | |

|

|

|

| opens and closes fre- |

|

|

|

|

|

|

| quently to finally operate |

|

|

|

|

|

|

| High Temperature Safety. |

|

|

|

| k) Water Solenoid | 1. | Mesh filter or orifice gets | 1. | Clean. | ||

|

|

|

| clogged and water supply |

|

|

|

|

|

|

| cycle does not finish. |

|

|

|

|

|

| 2. | Coil winding opened. | 2. | Replace. |

|

|

|

| 3. | Wiring to Water Valve. | 3. | Check for loose | |

|

|

|

|

|

| connection or open, and | |

|

|

|

|

|

| replace. | |

27