Hickory Industries, Inc.

1.4Conversion and Adjustment Instructions

Before converting or adjusting the machine, it is imperative that the manual gas cock be turned to the "off" position. The electrical power to the machines should also be turned off. When converting from one type of gas to another, the main gas orifice (or injector), the pilot burner orifice (or injector), and the primary air adjustment must be changed according to the table on page 9. In addition, the spring in the pressure regulator must be changed so that it can operate at higher pressures.

1.6Verification for use with Natural Gas

The highest flame setting ("on" position on the manifold gas valves) for each of the pipe burners can be confirmed by using the volumetric method in conjunction with the main gas meter. From the "pilot" position, turn the Gas Control Lever

To carry out this verification procedure, it is necessary to obtain the heating value (BTU/ft3) of the local gas from the local gas company.

If the measured gas volume does not correspond to the values in the following table, the first item which should be checked is the incoming (connected) gas pressure. If the pressure is correct, it must be verified that the proper size gas orifices are in place.

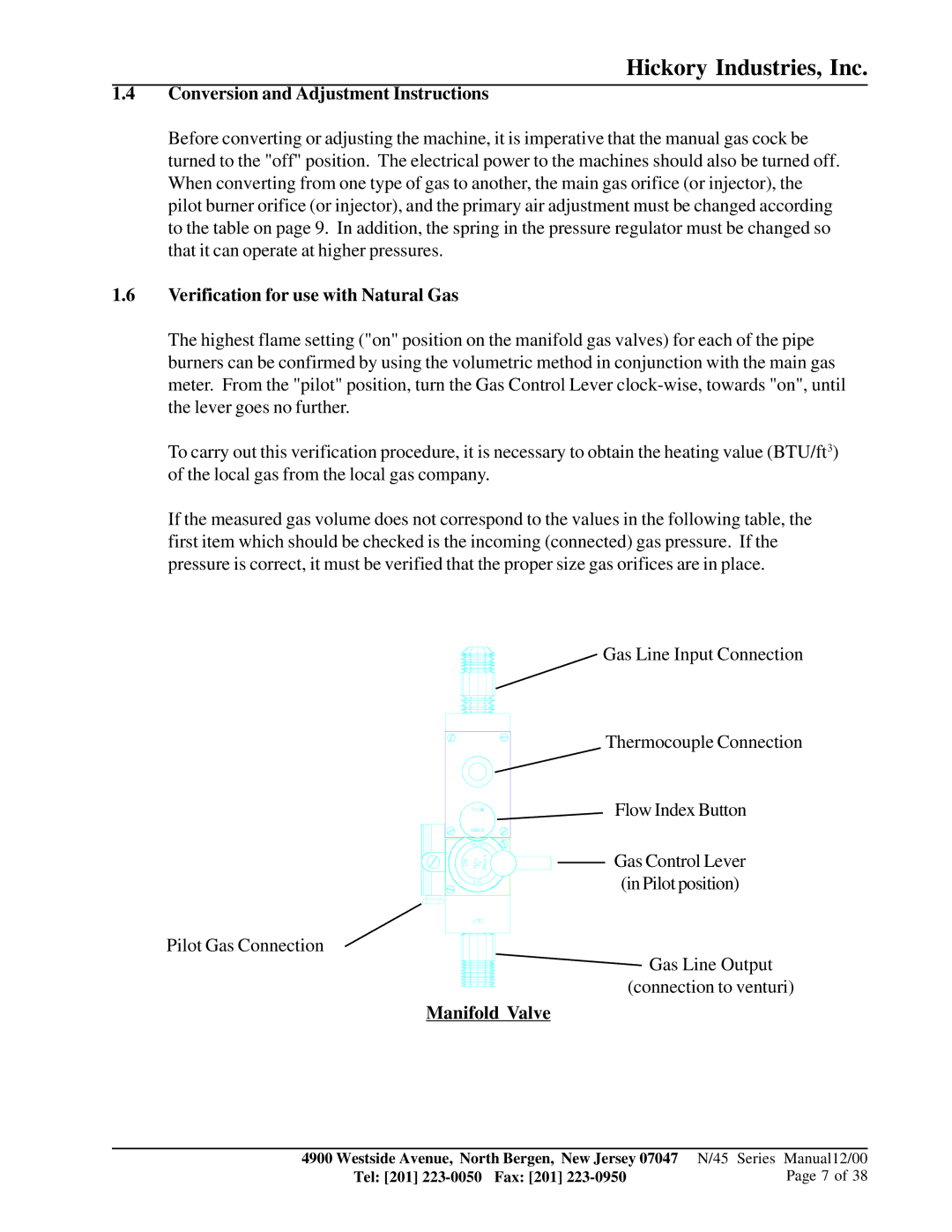

Gas Line Input Connection

Thermocouple Connection

Flow Index Button

Gas Control Lever (in Pilot position)

Pilot Gas Connection

![]() Gas Line Output

Gas Line Output

(connection to venturi)

Manifold Valve

4900 Westside Avenue, North Bergen, New Jersey 07047 | N/45 Series Manual12/00 |

Tel: [201] | Page 7 of 38 |