Repair Instructions

Pressure testing the carburettor

Pressure testing should be carried out with the car- burettor fully assembled. Testing should always be carried out after the carburettor has been repaired, but a test can also be made for troubleshooting before dismantling.

Option 1

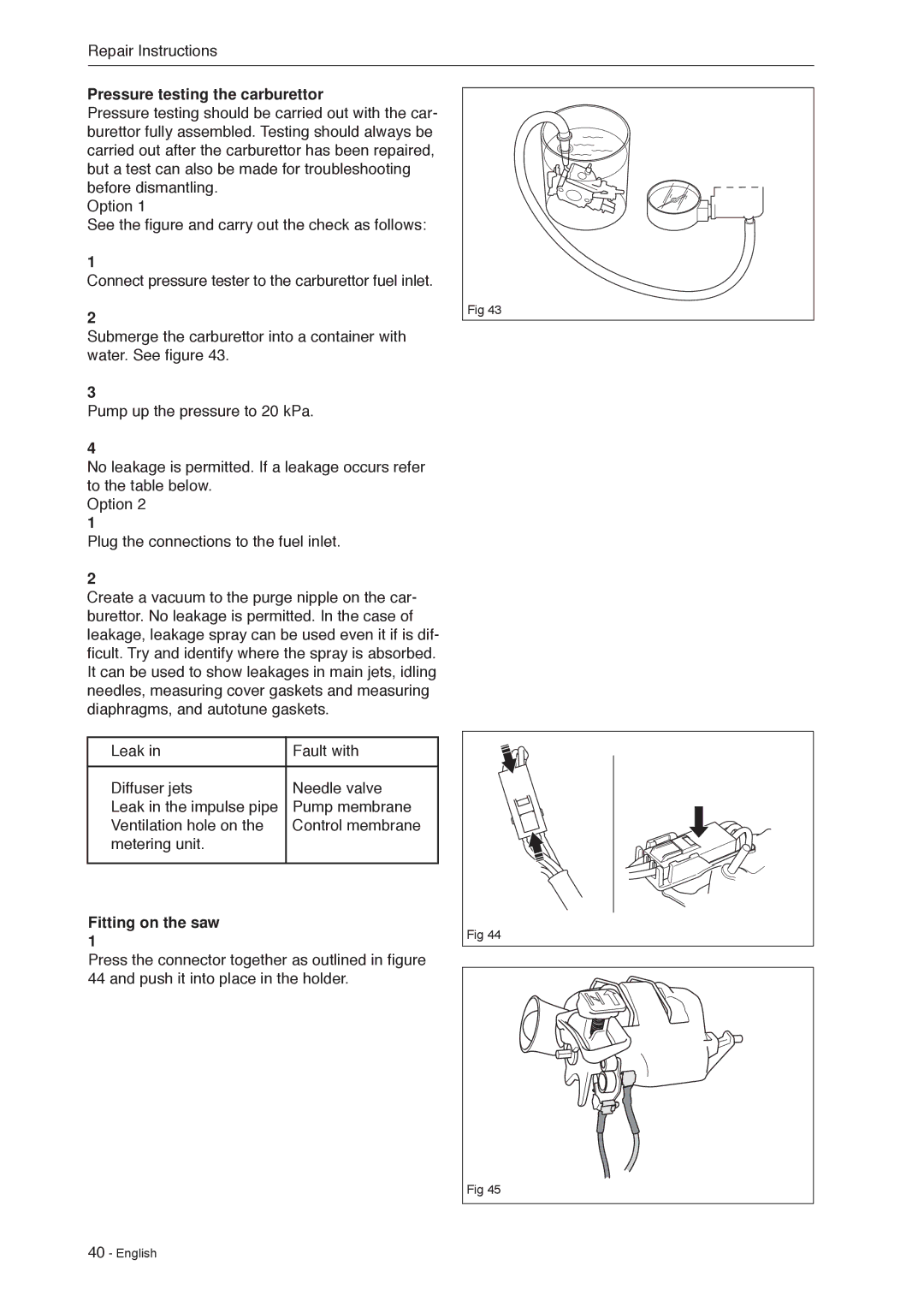

See the figure and carry out the check as follows:

1

Connect pressure tester to the carburettor fuel inlet.

2

Submerge the carburettor into a container with water. See figure 43.

3

Pump up the pressure to 20 kPa.

4

No leakage is permitted. If a leakage occurs refer to the table below.

Option 2

1

Plug the connections to the fuel inlet.

2

Create a vacuum to the purge nipple on the car- burettor. No leakage is permitted. In the case of leakage, leakage spray can be used even it if is dif- ficult. Try and identify where the spray is absorbed. It can be used to show leakages in main jets, idling needles, measuring cover gaskets and measuring diaphragms, and autotune gaskets.

Leak in | Fault with |

|

|

Diffuser jets | Needle valve |

Leak in the impulse pipe | Pump membrane |

Ventilation hole on the | Control membrane |

metering unit. |

|

|

|

Fitting on the saw

1

Press the connector together as outlined in figure 44 and push it into place in the holder.

Fig 43

Fig 44

Fig 45