Repair Instructions

Assembly

WARNING!

Beware of burn injuries as the crankcase halves are hot. Wear protective gloves.

1

Proceed as follows if a bearing must be fitted:

A. Heat up the crankcase half in question to 200°C. B. Use protective gloves. Fit the bearing in the

flywheel side of the crankcase half. When fitting the bearing in the clutch side of the crankcase half, the bearing must be fitted aligned with the inside of the crankcase.

C. Allow the crankcase half to cool down before continuing with the work.

NOTE!

Take care to prevent any dirt and foreign particles from entering the bearings.

D. Fit the oil refill cap.

2.

See page 52, figure 80, for how to fit new sealing rings.

NOTE!

Make sure the connecting rod is not crushed against the crankcase when the crankcase and crankshaft are fitted together.

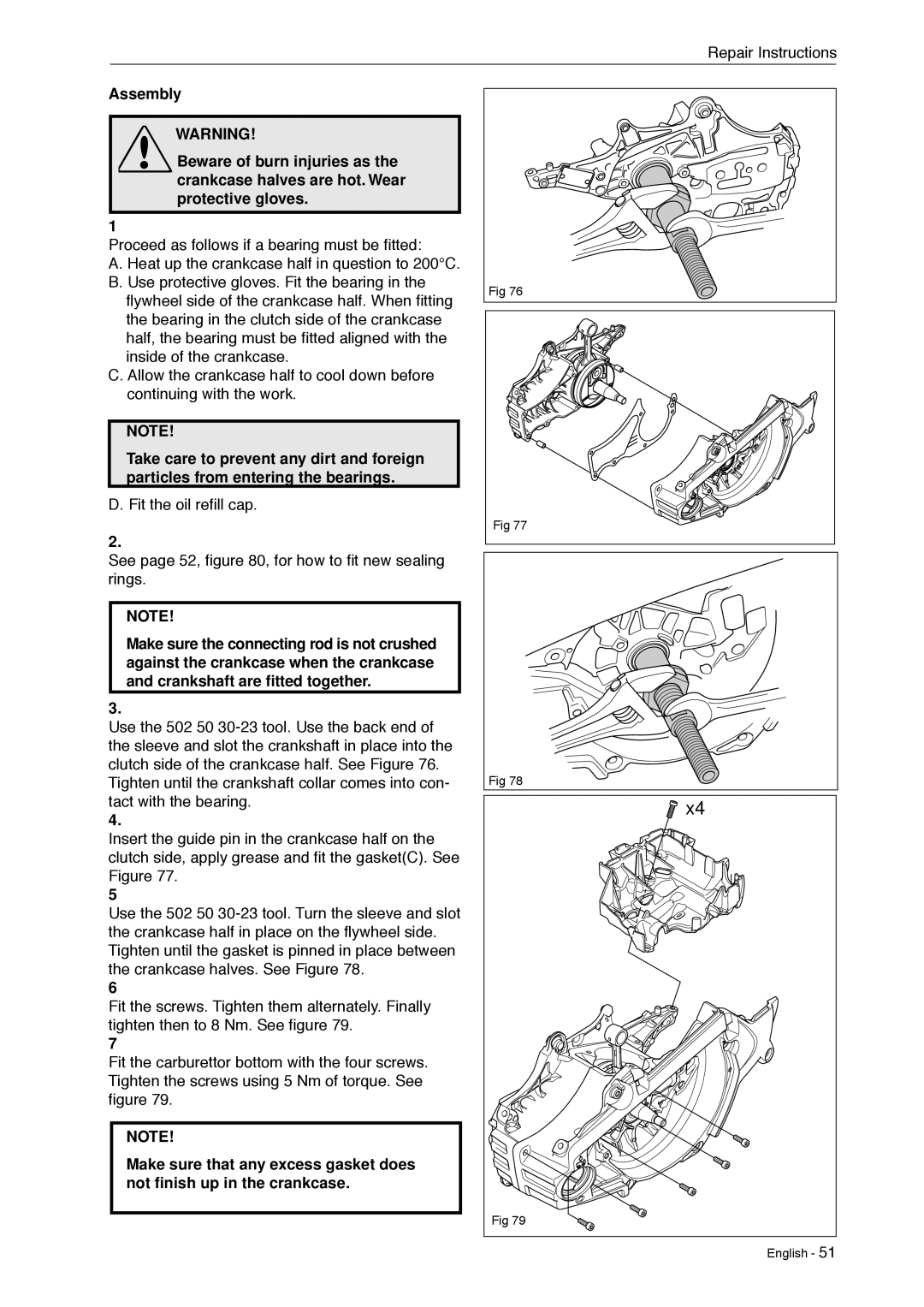

3.

Use the 502 50

4.

Insert the guide pin in the crankcase half on the clutch side, apply grease and fit the gasket(C). See Figure 77.

5

Use the 502 50

6

Fit the screws. Tighten them alternately. Finally tighten then to 8 Nm. See figure 79.

7

Fit the carburettor bottom with the four screws. Tighten the screws using 5 Nm of torque. See figure 79.

NOTE!

Make sure that any excess gasket does not finish up in the crankcase.

Fig 76

Fig 77 |

Fig 78

x4 |

Fig 79 |

English - 51 |