Repair Instructions

7.

If required, remove the crankshaft bearing from the crankcase.

Proceed as follows:

A. Remove the oil refill cap.

B. Heat up the crankcase half in question to 200°C. C. Use protective gloves. Press the bearing out of

the crankcase half.

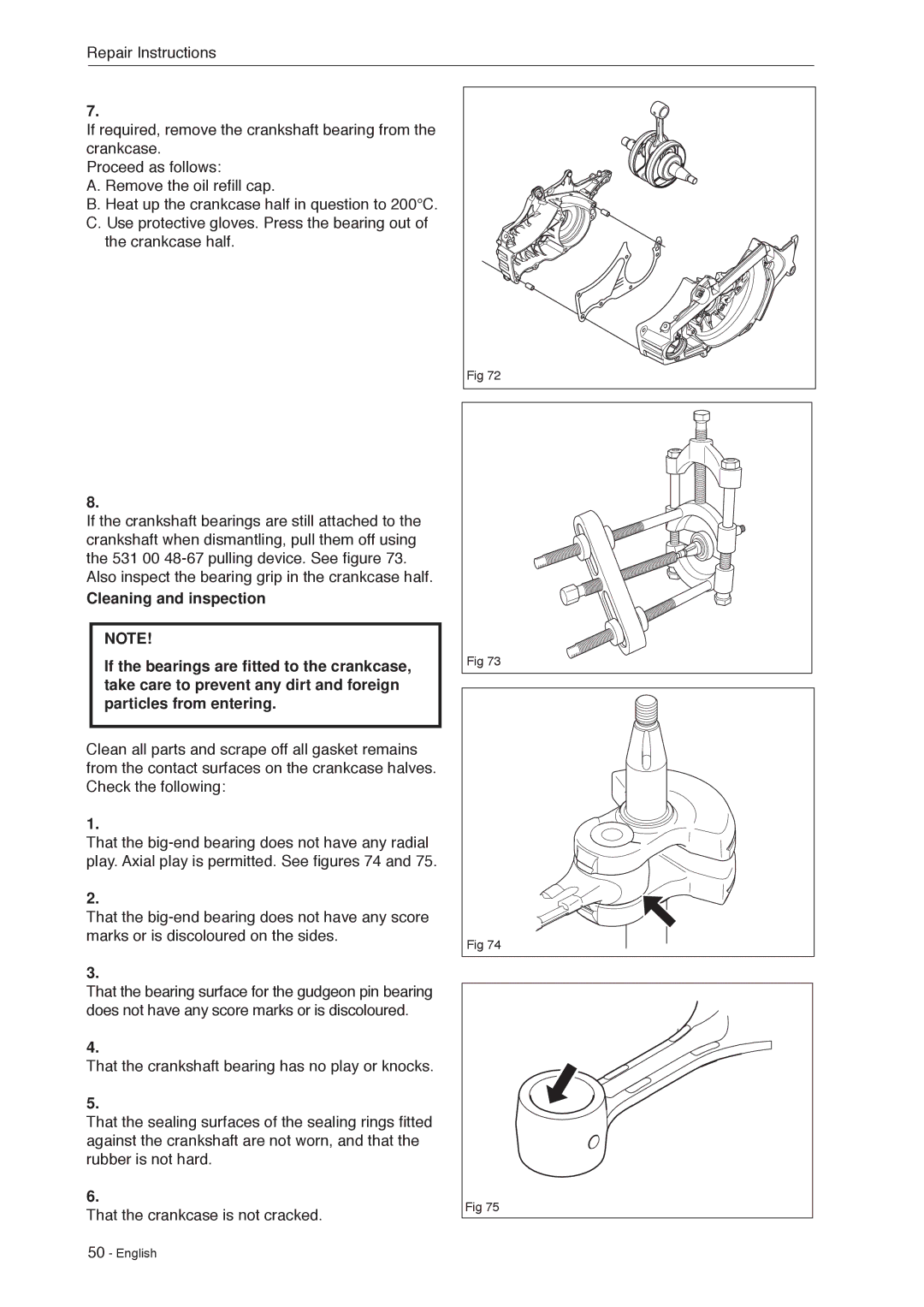

Fig 72 |

8.

If the crankshaft bearings are still attached to the crankshaft when dismantling, pull them off using the 531 00

Also inspect the bearing grip in the crankcase half.

Cleaning and inspection

NOTE!

If the bearings are fitted to the crankcase, take care to prevent any dirt and foreign particles from entering.

Clean all parts and scrape off all gasket remains from the contact surfaces on the crankcase halves. Check the following:

1.

That the

2.

That the

3.

That the bearing surface for the gudgeon pin bearing does not have any score marks or is discoloured.

4.

That the crankshaft bearing has no play or knocks.

5.

That the sealing surfaces of the sealing rings fitted against the crankshaft are not worn, and that the rubber is not hard.

6.

That the crankcase is not cracked. 50 - English

Fig 73

Fig 74

Fig 75