It is important to note that whenever an air filter element is cleaned by any method, the person or company performing the cleaning assumes responsibility for the integrity of the filter from then on. The warranty for air filters expires upon cleaning or servicing in any manner because the condition of the filter after servicing is completely out of their control. Therefore, on a dust ingested engine failure, there will be no warranty consideration if the air filter element has been cleaned or serviced in any manner.

A partially dirty air filter element works better than a new element. Therefore, a dirty filter element is not bad for the engine unless it is excessively restricting the air flow and engine performance is affected. The reason is simple. The media in the filter must be porous to allow air to pass through it. When dirty air passes through the filter, the dirt plugs some of the holes in the media and actually acts as part of the filter media. When the next round of dirt enters, the first dirt helps filter out even smaller particles making the filter more efficient at stopping dirt from entering the engine. This is referred to as barrier filtration.

Of course, at some point the filter media becomes too clogged to allow air to pass.

The mowing conditions will determine the frequency of air filter element changing.

Air filter

Figure

Cooling system

The 3500/3700 engine must operate at the correct temperature to obtain maximum efficiency and service life. This is dependent on the cooling system.

Always fill the system with a 50/50 solution of permanent antifreeze and clear water.

Checking the coolant level

WARNING: Always wear eye protection when ser- vicing the cooling system.

NOTE: Visually inspect the system daily prior to operating tractor. Be sure the engine is level. Open the hood, and check the coolant recovery reservoir located next to the battery. Check the coolant level only when the system is cold. Check the

coolant level only at the overflow reservoir (Figure

If the coolant recovery reservoir is low, refill system, with the proper coolant mixture, through the recovery reservoir. It is not necessary to remove the radiator cap to replenish the coolant. Engine cooling is accomplished with a 50/50 mixture of clear water and Ethylene Glycol

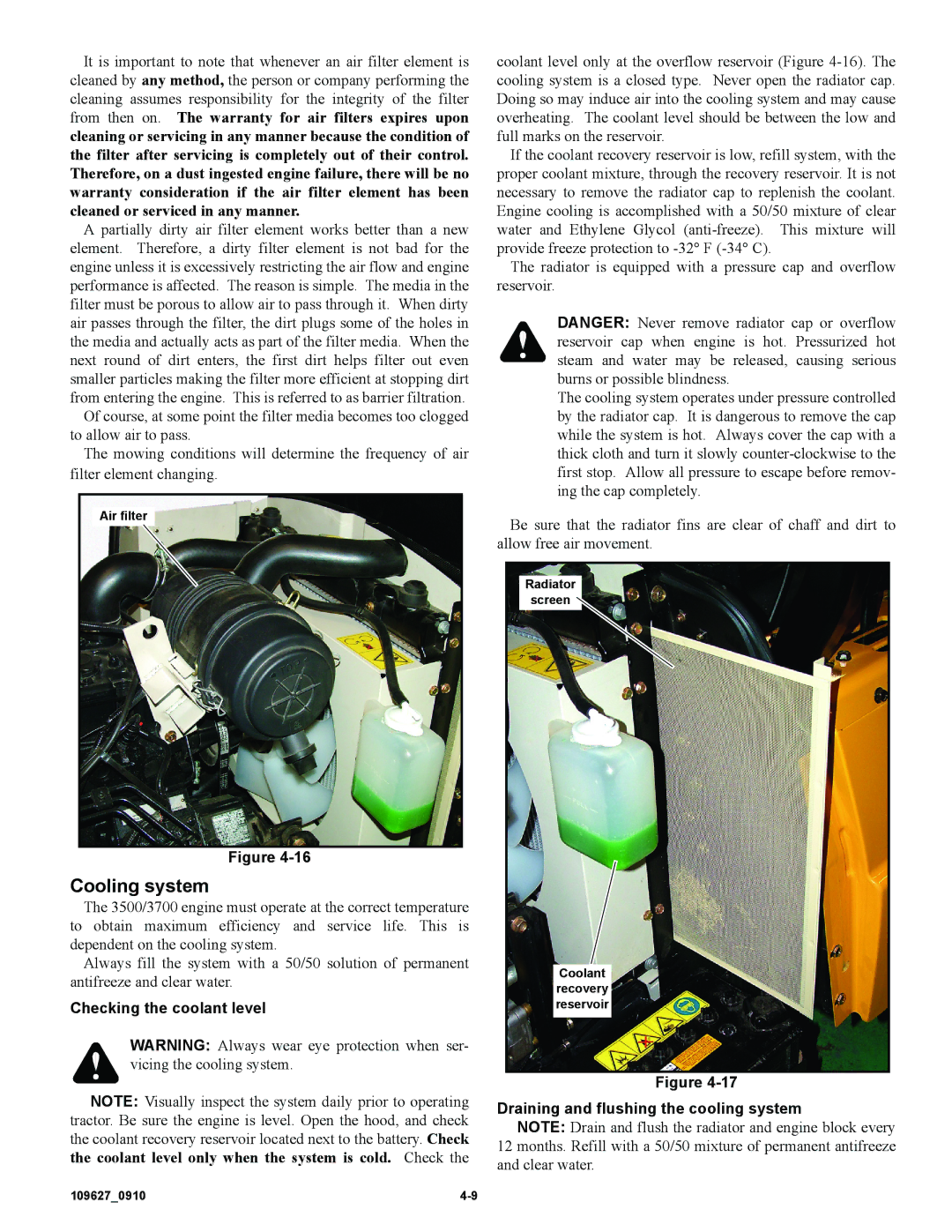

The radiator is equipped with a pressure cap and overflow reservoir.

DANGER: Never remove radiator cap or overflow reservoir cap when engine is hot. Pressurized hot steam and water may be released, causing serious burns or possible blindness.

The cooling system operates under pressure controlled by the radiator cap. It is dangerous to remove the cap while the system is hot. Always cover the cap with a thick cloth and turn it slowly

Be sure that the radiator fins are clear of chaff and dirt to allow free air movement.

Radiator screen ![]()

Coolant

recovery reservoir

Figure

Draining and flushing the cooling system

NOTE: Drain and flush the radiator and engine block every

12 months. Refill with a 50/50 mixture of permanent antifreeze and clear water.

109627_0910 |