English

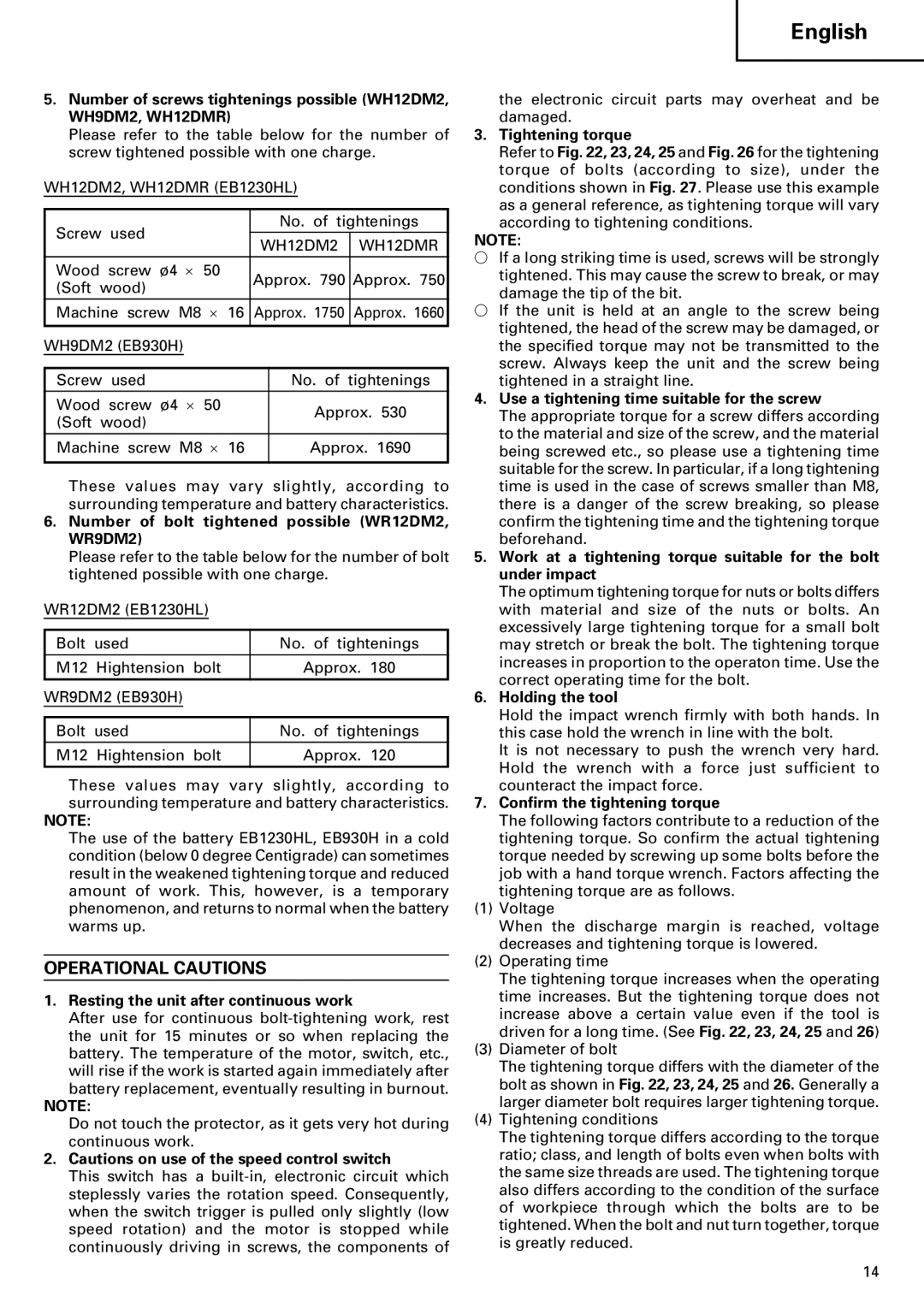

5.Number of screws tightenings possible (WH12DM2, WH9DM2, WH12DMR)

Please refer to the table below for the number of screw tightened possible with one charge.

WH12DM2, WH12DMR (EB1230HL)

Screw used | No. of tightenings | ||

WH12DM2 | WH12DMR | ||

| |||

Wood screw ø4 ⋅ 50 | Approx. 790 | Approx. 750 | |

(Soft wood) | |||

|

| ||

Machine screw M8 ⋅ 16 | Approx. 1750 | Approx. 1660 | |

|

|

| |

WH9DM2 (EB930H) |

|

| |

Screw used | No. of tightenings | |

Wood screw ø4 ⋅ 50 | Approx. 530 | |

(Soft wood) | ||

| ||

Machine screw M8 ⋅ 16 | Approx. 1690 | |

|

|

These values may vary slightly, according to surrounding temperature and battery characteristics.

6.Number of bolt tightened possible (WR12DM2, WR9DM2)

Please refer to the table below for the number of bolt tightened possible with one charge.

WR12DM2 (EB1230HL)

Bolt | used | No. of | tightenings | ||

M12 | Hightension bolt | Approx. | 180 | ||

WR9DM2 (EB930H) |

|

|

| ||

|

|

|

| ||

Bolt | used | No. of | tightenings | ||

M12 | Hightension bolt | Approx. | 120 | ||

These values may vary slightly, according to surrounding temperature and battery characteristics.

NOTE:

The use of the battery EB1230HL, EB930H in a cold condition (below 0 degree Centigrade) can sometimes result in the weakened tightening torque and reduced amount of work. This, however, is a temporary phenomenon, and returns to normal when the battery warms up.

OPERATIONAL CAUTIONS

1.Resting the unit after continuous work

After use for continuous

NOTE:

Do not touch the protector, as it gets very hot during continuous work.

2.Cautions on use of the speed control switch

This switch has a

the electronic circuit parts may overheat and be damaged.

3.Tightening torque

Refer to Fig. 22, 23, 24, 25 and Fig. 26 for the tightening torque of bolts (according to size), under the conditions shown in Fig. 27. Please use this example as a general reference, as tightening torque will vary according to tightening conditions.

NOTE:

◯If a long striking time is used, screws will be strongly tightened. This may cause the screw to break, or may damage the tip of the bit.

◯If the unit is held at an angle to the screw being tightened, the head of the screw may be damaged, or

the specified torque may not be transmitted to the screw. Always keep the unit and the screw being tightened in a straight line.

4.Use a tightening time suitable for the screw

The appropriate torque for a screw differs according to the material and size of the screw, and the material being screwed etc., so please use a tightening time suitable for the screw. In particular, if a long tightening time is used in the case of screws smaller than M8, there is a danger of the screw breaking, so please confirm the tightening time and the tightening torque beforehand.

5.Work at a tightening torque suitable for the bolt under impact

The optimum tightening torque for nuts or bolts differs with material and size of the nuts or bolts. An excessively large tightening torque for a small bolt may stretch or break the bolt. The tightening torque increases in proportion to the operaton time. Use the correct operating time for the bolt.

6.Holding the tool

Hold the impact wrench firmly with both hands. In this case hold the wrench in line with the bolt.

It is not necessary to push the wrench very hard. Hold the wrench with a force just sufficient to counteract the impact force.

7.Confirm the tightening torque

The following factors contribute to a reduction of the tightening torque. So confirm the actual tightening torque needed by screwing up some bolts before the

job with a hand torque wrench. Factors affecting the tightening torque are as follows.

(1)Voltage

When the discharge margin is reached, voltage decreases and tightening torque is lowered.

(2)Operating time

The tightening torque increases when the operating time increases. But the tightening torque does not increase above a certain value even if the tool is driven for a long time. (See Fig. 22, 23, 24, 25 and 26)

(3)Diameter of bolt

The tightening torque differs with the diameter of the bolt as shown in Fig. 22, 23, 24, 25 and 26. Generally a larger diameter bolt requires larger tightening torque.

(4)Tightening conditions

The tightening torque differs according to the torque ratio; class, and length of bolts even when bolts with the same size threads are used. The tightening torque also differs according to the condition of the surface of workpiece through which the bolts are to be tightened. When the bolt and nut turn together, torque is greatly reduced.

14