WH 12DM2 WR 12DM2 WH 12DMR WH 9DM2 WR 9DM2

WH12DM2 WR12DM2 WH12DMR

Page

Page

3mm

WR12DM2, WH12DMR

WR9DM2

Aaaa

WR9DM2 WH9DM2, WR9DM2

General Operational Precautions

Precautions for Cordless Impact Driver

Model

Precautions for Cordless Impact Wrench

Specifications

Cordless Impact Driver

Charger

Standard Accessories

Optional Accessories

For WH12DM2, WH9DM2, WH12DMR

For WR9DM2

For WR12DM2, WR9DM2 Sockets

For WR12DM2

Long Socket

Extension bar WR12DM2 Code No WR9DM2 Code No

Universal joint WR12DM2 Code No WR9DM2 Code No

Duct Socket WR12DM2

Battery REMOVAL/INSTALLATION

Application

Charging

Prior to Operation

Hold the charger firmly and pull out the battery. Note

How to make the batteries perform longer

Regarding electric discharge in case of new batteries, etc

Switch operation

HOW to USE

Using the light equipped hook

Check the rotational direction

Operational Cautions

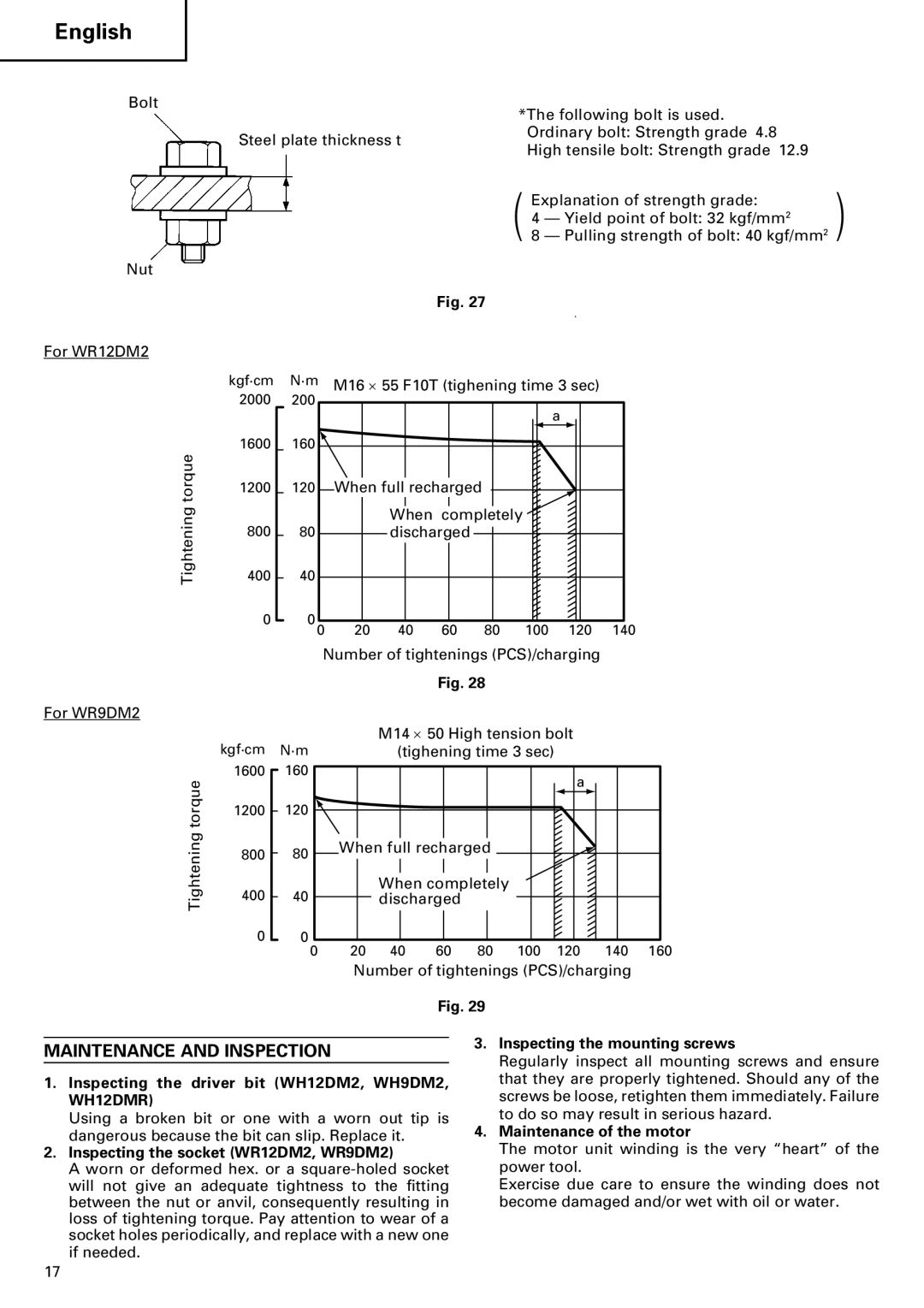

29 show examples of the relationship

For WH12DMR

Inspecting the driver bit WH12DM2, WH9DM2, WH12DMR

Maintenance and Inspection

Maintenance of the motor

Inspecting the socket WR12DM2, WR9DM2

Modifications

Vorsicht FÜR Allgemeine Bedienung

Vorsichtsmassnahmen FÜR DEN AKKU- Schlagschrauber

Modell

Standardzubehör

AKKU-SCHLAGSCHRAUBER

Ladegerät

Sonderzubehör

Lange Buchse

Für WR12DM2 Tafel

Für WR9DM2 Tafel

Für WR12DM2

Achtung

Hinweis

Anwendung

HERAUSNEHMEN/EINSETZEN DER Batterie

Laden

VOR Inbetriebnahme

WH9DM2, WH12DMR

Die Drehrichtung nachprüfen

Verwendung

Verwendung des Hakens mit Beleuchtung

Schalterbetätigung

Vorsichtsmassregeln ZUR Verwendung

Zahl der möglichen Bolzen-Fest-spannungen WR12DM2, WR9DM2

Lassen Sie das Gerät nach fortlaufender Verwendung ruhen

Überprüfung des Anzugsdrehmoments

Abb

M8 ⋅ 1000

Für WR12DM2

120 140 Zahl der Festspannung Stück/Aufladung

Wartung UND Inspektion

Modifikationen

Precautions Generales

Precautions Pour LA Perceuse À Percussion SUR Batterie

Precautions Pour LA Visseuse À Percussion SUR Batterie

Modéle

Perceuse à percussion sur batterie

Visseuse à percussion sur batterie

Chargeur

Accessoires Standards

Accessoires SUR Option

Pour WR12DM2 Tableau

Pour WR9DM2 Tableau

Douille longue

Joint universel WR12DM2 No de code 992610 WR9DM2 No de code

Douille à tubulure WR12DM2

Extraction ET Installation DE LA Batterie

Charge

Remarque

Mise en place de la mèche WH12DM2, WH9DM2, WH12DMR

Avant LA Mise EN Marche

Comment prolonger la durée de vie des batteries

Mise in place d’une douille WR12DM2, WR9DM2

Vérifiez le sens de rotation

Utilisation

Utilisation d’un crochet muni d’un éclairage

Fonctionnement de l’interrupteur

Precautions DE Fonctionnement

Serrage 1200 M10 1000

1000 800 Boulon hautement Extensible 600

Pour WR12DM2

Pour WR12DM2 M16 ⋅ 55 F10T Temps de serrage 3 sec

Entretien ET Controle

Italiano

Precauzioni PER LE Operazioni Generali

Modello

Avvitatore a impulso a batteria per bulloni

Caratteristiche

Avvitatore a impulso a batteria per viti

Caricatore

Per WH12DM2, WH9DM2, WH12DMR

Accessori Standard

Accessori Facoltativi

Cacciavite a croce

Per WR9DM2 Tabella

Per WR12DM2, WR9DM2 Chiavi a incavo

Per WR12DM2 Tabella

Chiave a tubo

Attenzione

Chiave a condotto WR12DM2

Ricarica

Rimozione E Installazione Della Battera

Applicazioni

Nota

Prima DI Iniziare LE Operazioni

Scarica nel caso di batterie nuove, ecc

Come mantenere più lunga la durata delle batterie

Controllare la direzione della rotazione

Operazione

Uso del gancio munito di lampada

Uso dell’interruttore

Precauzioni NELL’USO

Controllo della forza di serraggio

Nelle tabelle 1, 2, 3 e

25 e

M8 ⋅ 1000 800

200 Bullone ad alta

Per WR12DM2 Kgf·cm N·m 2000

Manutenzione E Controlli

Modifiche

Algemene Voorzorgsmaatregelen

Voorzorgen Voor DE Snoerloze Slagschroevendraaier

Voorzorgen Voor DE Snoerloze Slagsleutel

Technische Gegevens

Standaard Toebehoren

Acculader

Voor WR12DM2, WR9DM2 Bussen

Zeskante dopsleutel

Houtboor Code Nr Boorkop adapter-set Code Nr

Voor WR12DM2 Tabel

Voor WR9DM2 Tabel

Lange Bus

Voor WR12DM2

Opladen

Toepassingen

Inleggen EN Uitnemen VAN DE Batterij

LET OP

Betreffende het ontladen raken van nieuwe batterij e.d

Rood

Groen

Om langdurig gebruik van de batterij te bevorderen

Voor HET Gebruik

Gebruik

Voorzorgsmaatregelen BIJ Gebruik

Vasthouden van het gereedschap

Gebruik de juiste vastdraaitijd voor de schroef

Zet de bout met het juiste aantrekkoppel vast

Controleren van het aantrekkopper

Afb

Voor WH12DMR

Nederlands

Onderhoud EN Inspectie

Voorzichtig

Modificaties

Precauciones Generales DE Operacion

Precauciones Para EL Atornillador DE Impacto a Batería

Precauciones Para LA Llave DE Impacto a Batería

Modelo

Llave de impacto a batería

Especificaciones

Atornillador de impacto a batería

Cargador

Para WH12DM2, WH9DM2, WH12DMR

Accesorios Estándar

Accesorios Opcionales

Destornillador en cruz +

Cubo largo

Para WR12DM2 Tabla

Para WR9DM2 Tabla

Para WR12DM2

Junta cardánica WR12DM2 Código n˚ 992610 WR9DM2 Código n˚

Aplicación

Precaución

Cubo para conductos WR12DM2

Desmontaje de la batería

Desmontaje E Instalación DE Batería

Carga

Tabla Inserte la batería en el cargador

Forma de hacer que las baterías duren más

Como SE USA

Descarga eléctrica en caso de baterías nuevas, etc

Antes DE Usar LA Herramienta

Operación de conmutación

Uso del gancho equipado con luz

Comprobación de la dirección de rotación

Apretado y aflojado de pernos WH12DM2, WH9DM2, WH12DMR

Emplee el tiempo de apriete adecuado al tornillo

Precauciones Operacionales

Par de apriete

Confirmación de la tensión de apriete

Percusión de la herramienta se debilitará, el número

Para WH12DMR

·m M16 ⋅ 55 F10T Tiempo de apriete 3 seg

Mantenimiento E Inspección

Modificaciones

Precauções Gerais Quanto À Operação

Hitachi

Precauções COM a Aparafusadora DE Impacto a Bateria

Precauções COM a Chave DE Impacto a Bateria

Modelo

Aparafusadora de impacto a bateria

Especificações

ACESSÓRIOS-PADRÃO

Chave de impacto a bateria

Para WH12DM2, WH9DM2, WH12DMR 1. Palhetão de chave mais

Encaixe sextavado

Para WR12DM2 Quadro

Para WR9DM2 Quadro

Encaixe longo

Recarga

Aplicações

RETIRADA/INSTALAÇÃO DA Bateria

Cuidado

Vermelho

Quanto à descarga elétrica no caso de novas baterias, etc

Como prolongar a vida útil das baterias

Instalação da palheta WH12DM2, WH9DM2, WH12DMR

Antes DE Usar

Modo DE Usar

Uso do gancho equipado com luz

Precauções Operacionais

Para segurar a ferramenta

Confirmação do torque de aperto

800 Tração

800 600 Torque 400

120 140 160 Número de apertos PCS/recargas 104

Manutenção E Inspeção

Modificação

∂ÏÏËÓÈο

¶ƒ√ºÀ§∞∆π∞ ª∂∆ƒ∞ π∞ ∆√ ª¶√À§√¡√§∂π¢√

∆∂áπ∞ Ã∞ƒ∞∆∏ƒπ∆π∞

EB9B

¶ƒ√∞πƒ∂∆π∞ ∂∞ƒ∆∏ª∞∆∞ ¶ˆÏÔ‡ÓÙ·È Í¯ˆÚÈÛÙ¿

· WR9DM2 ¶›Ó·Î·˜

∂º∞ƒª√∂

›Ó·Î· ¶›Ó·Î·˜

Πρασιν

¶ƒπ¡ ∆∏ §∂π∆√Àƒπ∞

›ÍÈÌÔ Î·È ÍÂÛÊ›ÍÈÌÔ ‚ȉÒÓ WH12DM2, WH9DM2, WH12DMR

∏ª∂π∞ ¶ƒ√√Ã∏ ∞∆∞ ∆∏ §∂π∆√Àƒπ∞

∂ÈÎ , 23, 24, 25 και

Για WH9DM2

Για WR12DM2

119

¡∆∏ƒ∏∏ ∞π ∂§∂Ã√

WH12DM2

6901VVCMPS2L DC12V

M4 ⋅ EB1230HL EB1220BL

40,42-44 D2 ⋅ M4 ⋅ EB1220BL

WH9DM2

6901VVCMPS2L

WR9DM2

Certificat DE Garantie Certificado DE Garantia

Guarantee Certificate Garantiebewijs

Garantieschein Certificado DE Garantia

Certificato DI Garanzia

127

128

EC Declaration of Conformity EC Verklaring VAN Conformiteit

Declaration DE Conformite CE Declaração DE Conformidade CE

Dichiarazione DI Conformità CE EK ∆ΗΛΩΣΗ Εναρμ