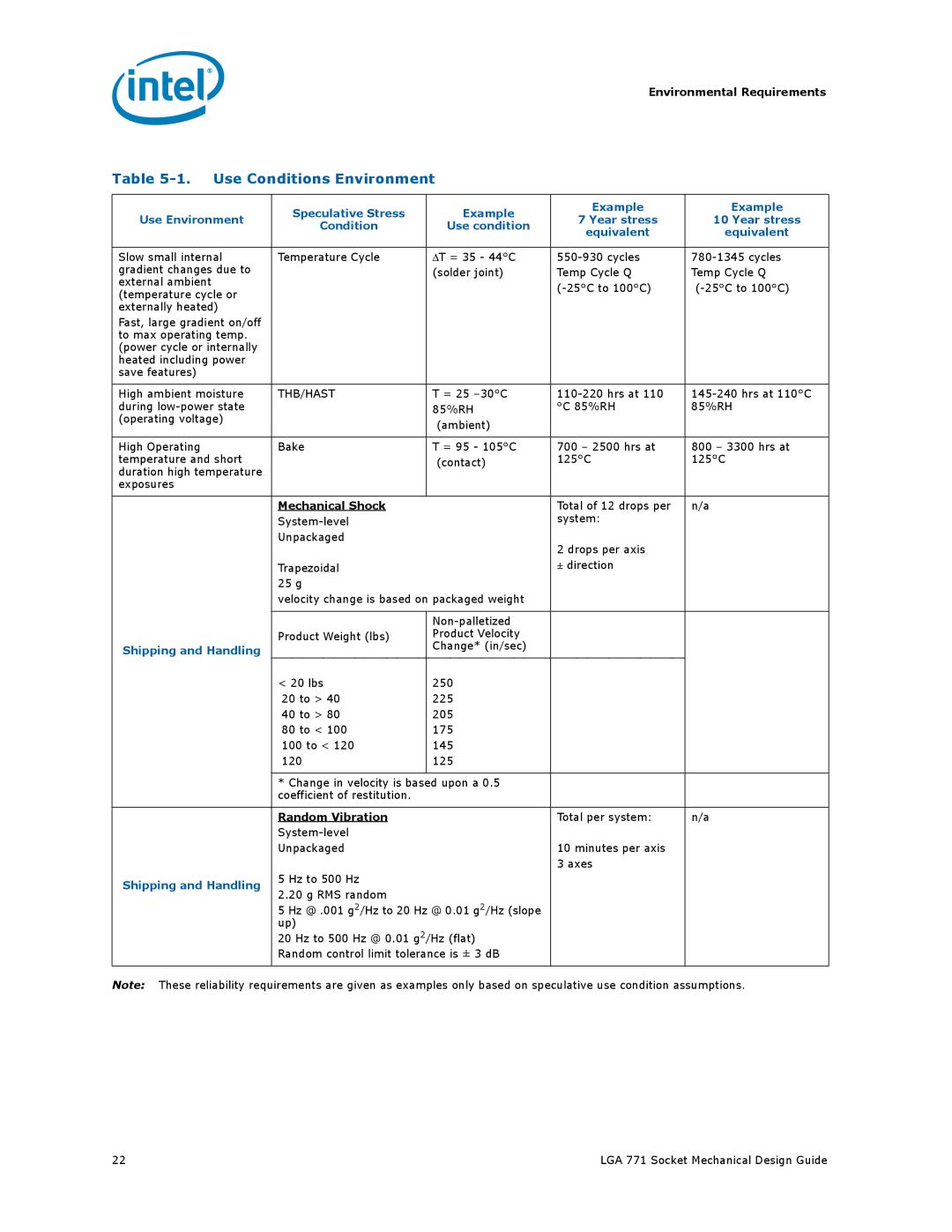

Environmental Requirements

Table | Use Conditions Environment |

|

| |||

|

|

|

|

|

| |

Use Environment | Speculative Stress | Example | Example | Example | ||

7 Year stress | 10 Year stress | |||||

Condition | Use condition | |||||

|

| equivalent | equivalent | |||

|

|

|

| |||

|

|

|

|

| ||

Slow small internal | Temperature Cycle | ΔT = 35 - 44°C | ||||

gradient changes due to |

| (solder joint) | Temp Cycle Q | Temp Cycle Q | ||

external ambient |

|

|

| |||

(temperature cycle or |

|

| ||||

|

|

|

| |||

externally heated) |

|

|

|

| ||

Fast, large gradient on/off |

|

|

|

| ||

to max operating temp. |

|

|

|

| ||

(power cycle or internally |

|

|

|

| ||

heated including power |

|

|

|

| ||

save features) |

|

|

|

|

| |

|

|

|

|

| ||

High ambient moisture | THB/HAST | T = 25 | ||||

during |

| 85%RH | °C 85%RH | 85%RH | ||

(operating voltage) |

| (ambient) |

|

| ||

|

|

|

|

| ||

|

|

|

|

|

| |

High Operating |

| Bake | T = 95 - 105°C | 700 – 2500 hrs at | 800 – 3300 hrs at | |

temperature and short |

| (contact) | 125°C | 125°C | ||

duration high temperature |

|

|

|

| ||

exposures |

|

|

|

|

| |

|

|

|

|

|

| |

|

| Mechanical Shock |

| Total of 12 drops per | n/a | |

|

|

| system: |

| ||

|

| Unpackaged |

| 2 drops per axis |

| |

|

|

|

|

| ||

|

| Trapezoidal |

| ± direction |

| |

|

| 25 g |

|

|

| |

|

| velocity change is based on packaged weight |

|

| ||

|

|

|

|

|

| |

|

|

|

|

| ||

|

| Product Weight (lbs) | Product Velocity |

|

| |

Shipping and Handling |

| Change* (in/sec) |

|

| ||

|

|

|

| |||

|

| < 20 lbs | 250 |

|

| |

|

| 20 to > 40 | 225 |

|

| |

|

| 40 to > 80 | 205 |

|

| |

|

| 80 to < 100 | 175 |

|

| |

|

| 100 to < 120 | 145 |

|

| |

|

| 120 | 125 |

|

| |

|

|

|

|

|

| |

|

| * Change in velocity is based upon a 0.5 |

|

| ||

|

| coefficient of restitution. |

|

|

| |

|

|

|

|

|

| |

|

| Random Vibration |

| Total per system: | n/a | |

|

|

|

|

| ||

|

| Unpackaged |

| 10 minutes per axis |

| |

|

|

|

| 3 axes |

| |

Shipping and Handling | 5 Hz to 500 Hz |

|

|

| ||

2.20 g RMS random |

|

|

| |||

|

|

|

|

| ||

|

| 5 Hz @ .001 g2/Hz to 20 Hz @ 0.01 g2/Hz (slope |

|

| ||

|

| up) |

|

|

| |

|

| 20 Hz to 500 Hz @ 0.01 g2/Hz (flat) |

|

| ||

|

| Random control limit tolerance is ± 3 dB |

|

| ||

|

|

|

|

| ||

Note: These reliability requirements are given as examples only based on speculative use condition assumptions. | ||||||

22 | LGA 771 Socket Mechanical Design Guide |