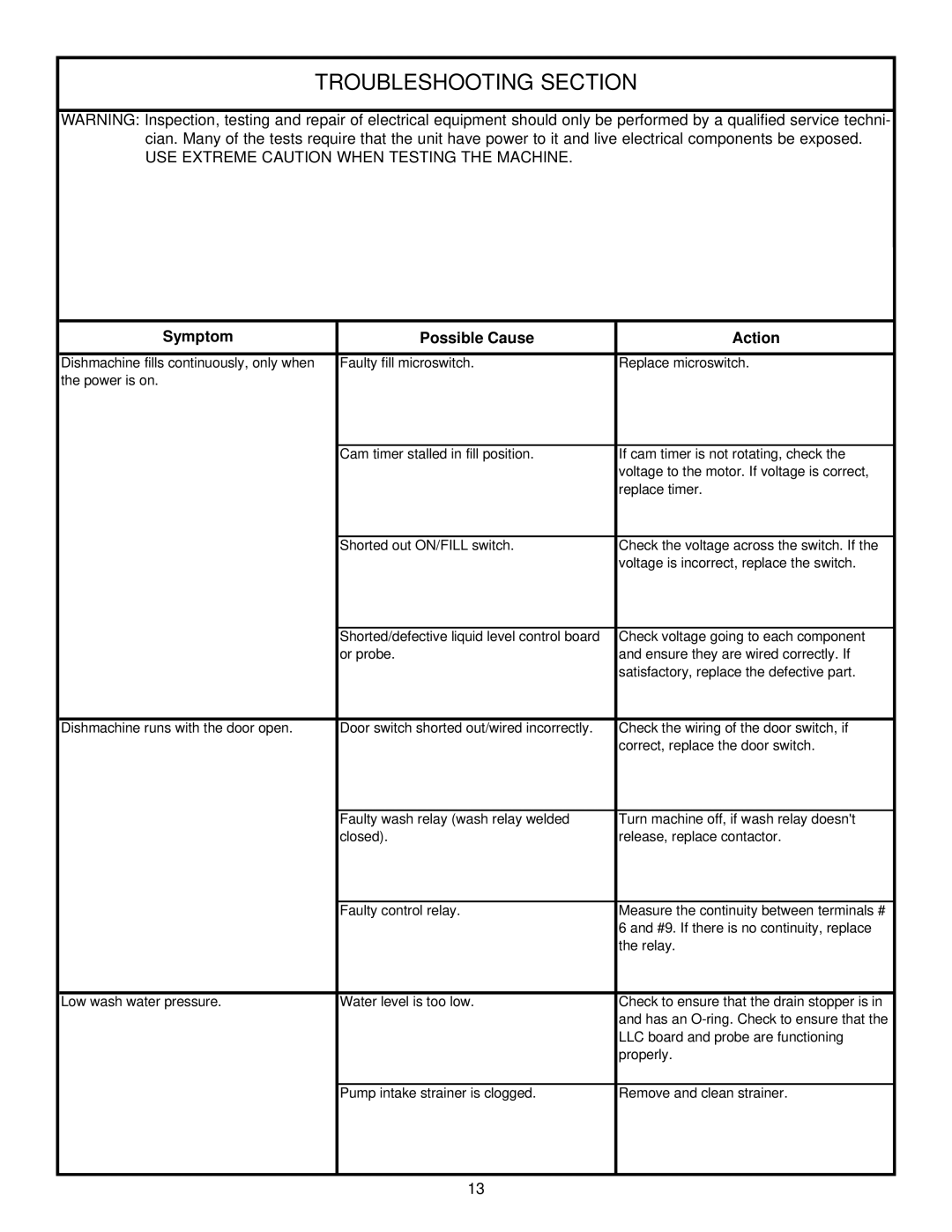

TROUBLESHOOTING SECTION

WARNING: Inspection, testing and repair of electrical equipment should only be performed by a qualified service techni- cian. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

|

|

|

|

|

| Symptom | Possible Cause | Action |

|

|

|

|

|

|

| Dishmachine fills continuously, only when | Faulty fill microswitch. | Replace microswitch. |

|

| the power is on. |

|

|

|

|

|

|

|

|

|

| Cam timer stalled in fill position. | If cam timer is not rotating, check the |

|

|

|

| voltage to the motor. If voltage is correct, |

|

|

|

| replace timer. |

|

|

|

|

|

|

|

| Shorted out ON/FILL switch. | Check the voltage across the switch. If the |

|

|

|

| voltage is incorrect, replace the switch. |

|

|

|

|

|

|

|

| Shorted/defective liquid level control board | Check voltage going to each component |

|

|

| or probe. | and ensure they are wired correctly. If |

|

|

|

| satisfactory, replace the defective part. |

|

|

|

|

|

|

| Dishmachine runs with the door open. | Door switch shorted out/wired incorrectly. | Check the wiring of the door switch, if |

|

|

|

| correct, replace the door switch. |

|

|

|

|

|

|

|

| Faulty wash relay (wash relay welded | Turn machine off, if wash relay doesn't |

|

|

| closed). | release, replace contactor. |

|

|

|

|

|

|

|

| Faulty control relay. | Measure the continuity between terminals # |

|

|

|

| 6 and #9. If there is no continuity, replace |

|

|

|

| the relay. |

|

|

|

|

|

|

| Low wash water pressure. | Water level is too low. | Check to ensure that the drain stopper is in |

|

|

|

| and has an |

|

|

|

| LLC board and probe are functioning |

|

|

|

| properly. |

|

|

|

|

|

|

|

| Pump intake strainer is clogged. | Remove and clean strainer. |

|

|

|

|

|

|

13