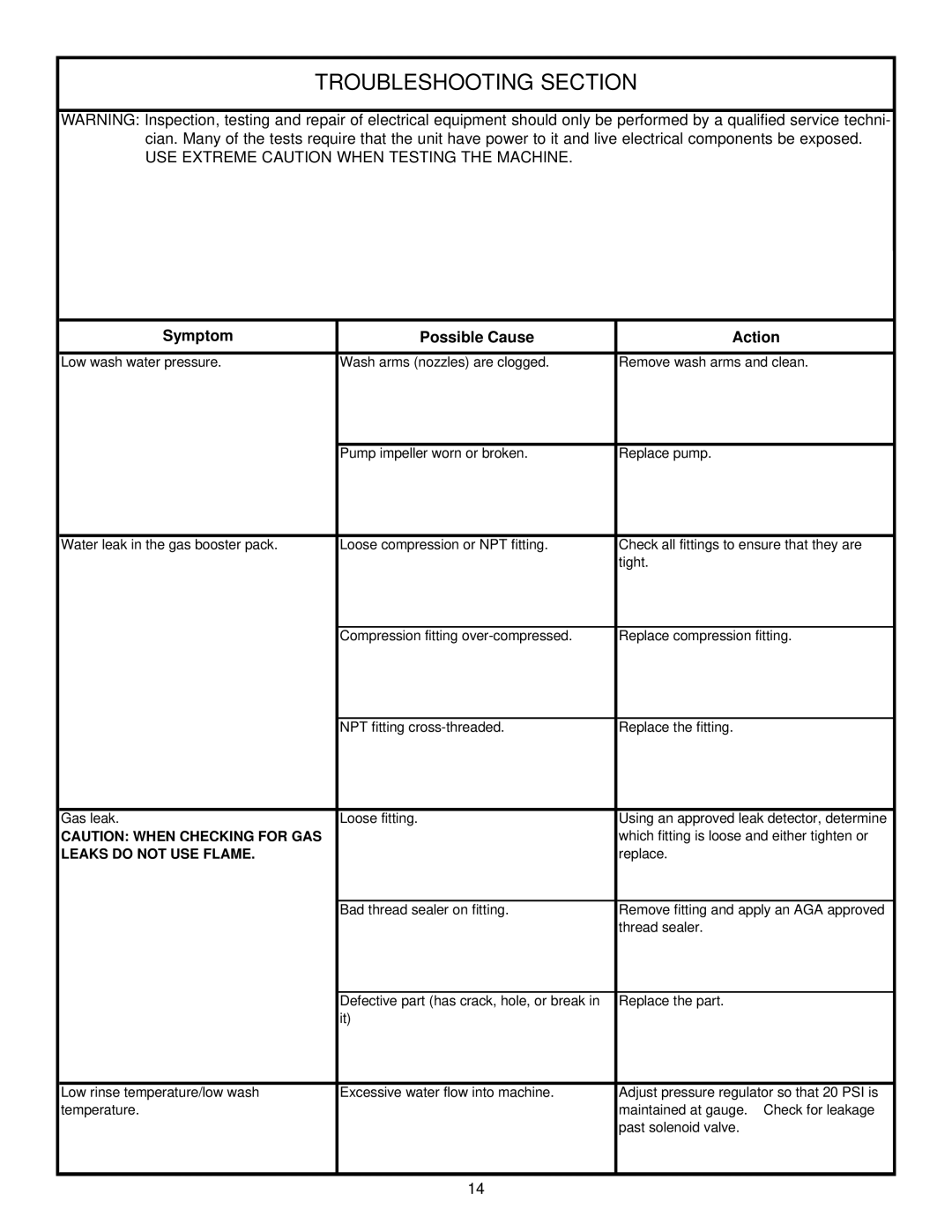

TROUBLESHOOTING SECTION

WARNING: Inspection, testing and repair of electrical equipment should only be performed by a qualified service techni- cian. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

|

|

|

|

|

| Symptom | Possible Cause | Action |

|

|

|

|

|

|

| Low wash water pressure. | Wash arms (nozzles) are clogged. | Remove wash arms and clean. |

|

|

|

|

|

|

|

| Pump impeller worn or broken. | Replace pump. |

|

|

|

|

|

|

| Water leak in the gas booster pack. | Loose compression or NPT fitting. | Check all fittings to ensure that they are |

|

|

|

| tight. |

|

|

|

|

|

|

|

| Compression fitting | Replace compression fitting. |

|

|

|

|

|

|

|

| NPT fitting | Replace the fitting. |

|

|

|

|

|

|

| Gas leak. | Loose fitting. | Using an approved leak detector, determine |

|

| CAUTION: WHEN CHECKING FOR GAS |

| which fitting is loose and either tighten or |

|

| LEAKS DO NOT USE FLAME. |

| replace. |

|

|

|

|

|

|

|

| Bad thread sealer on fitting. | Remove fitting and apply an AGA approved |

|

|

|

| thread sealer. |

|

|

|

|

|

|

|

| Defective part (has crack, hole, or break in | Replace the part. |

|

|

| it) |

|

|

|

|

|

|

|

| Low rinse temperature/low wash | Excessive water flow into machine. | Adjust pressure regulator so that 20 PSI is |

|

| temperature. |

| maintained at gauge. Check for leakage |

|

|

|

| past solenoid valve. |

|

|

|

|

|

|

14