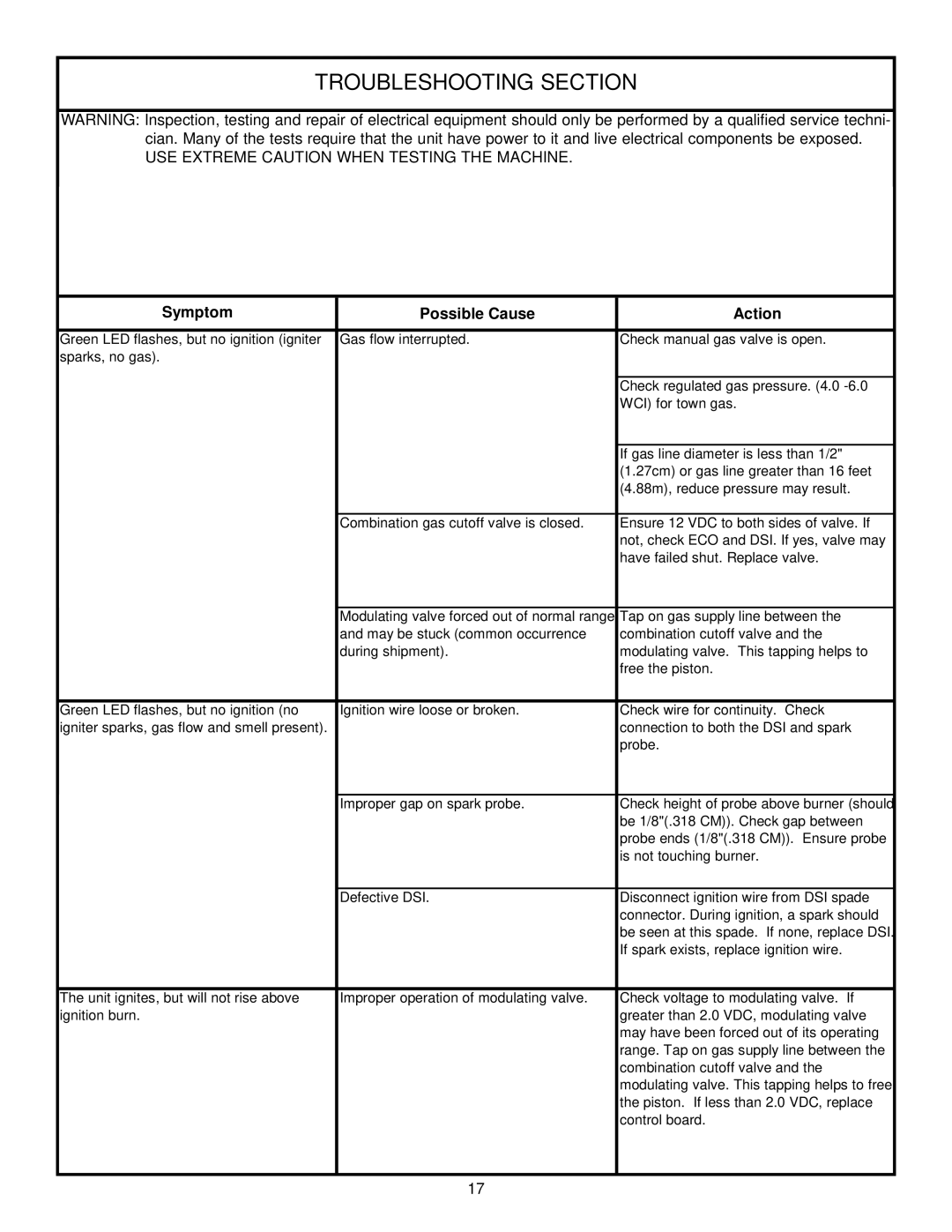

TROUBLESHOOTING SECTION

WARNING: Inspection, testing and repair of electrical equipment should only be performed by a qualified service techni- cian. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

|

|

|

|

|

| Symptom | Possible Cause | Action |

|

|

|

|

|

|

| Green LED flashes, but no ignition (igniter | Gas flow interrupted. | Check manual gas valve is open. |

|

| sparks, no gas). |

|

|

|

|

|

|

|

|

|

|

| Check regulated gas pressure. (4.0 |

|

|

|

| WCI) for town gas. |

|

|

|

|

|

|

|

|

| If gas line diameter is less than 1/2" |

|

|

|

| (1.27cm) or gas line greater than 16 feet |

|

|

|

| (4.88m), reduce pressure may result. |

|

|

|

|

|

|

|

| Combination gas cutoff valve is closed. | Ensure 12 VDC to both sides of valve. If |

|

|

|

| not, check ECO and DSI. If yes, valve may |

|

|

|

| have failed shut. Replace valve. |

|

|

|

|

|

|

|

| Modulating valve forced out of normal range | Tap on gas supply line between the |

|

|

| and may be stuck (common occurrence | combination cutoff valve and the |

|

|

| during shipment). | modulating valve. This tapping helps to |

|

|

|

| free the piston. |

|

|

|

|

|

|

| Green LED flashes, but no ignition (no | Ignition wire loose or broken. | Check wire for continuity. Check |

|

| igniter sparks, gas flow and smell present). |

| connection to both the DSI and spark |

|

|

|

| probe. |

|

|

|

|

|

|

|

| Improper gap on spark probe. | Check height of probe above burner (should |

|

|

|

| be 1/8"(.318 CM)). Check gap between |

|

|

|

| probe ends (1/8"(.318 CM)). Ensure probe |

|

|

|

| is not touching burner. |

|

|

|

|

|

|

|

| Defective DSI. | Disconnect ignition wire from DSI spade |

|

|

|

| connector. During ignition, a spark should |

|

|

|

| be seen at this spade. If none, replace DSI. |

|

|

|

| If spark exists, replace ignition wire. |

|

|

|

|

|

|

| The unit ignites, but will not rise above | Improper operation of modulating valve. | Check voltage to modulating valve. If |

|

| ignition burn. |

| greater than 2.0 VDC, modulating valve |

|

|

|

| may have been forced out of its operating |

|

|

|

| range. Tap on gas supply line between the |

|

|

|

| combination cutoff valve and the |

|

|

|

| modulating valve. This tapping helps to free |

|

|

|

| the piston. If less than 2.0 VDC, replace |

|

|

|

| control board. |

|

|

|

|

|

|

17