Operations

(NOTE: The following Figures may or may not show your specific saw, but the procedures are the same.)

Table Saws

Familiarize yourself with the location and operation of all controls and adjustments and the use of accessories such as the miter gauge and rip fence.

Kickbacks

Serious injury can result from kickbacks which occur when a work piece binds on the saw blade or binds between the saw blade and rip fence or other fixed object. This binding can cause the work piece to lift up and be thrown toward the operator.

Listed below are conditions, which can cause kickbacks:

!Confining the cutoff piece when crosscutting or ripping.

!Releasing the work piece before completing the operation or not pushing the work piece all the way past the saw blade.

!Not using the splitter when ripping or not maintaining alignment of the splitter with the saw blade.

!Using a dull saw blade.

!Not maintaining alignment of the rip fence so that it tends to angle toward rather than away from the saw blade front to back.

!Applying feed force when ripping to the cutoff (free) section of the work piece instead of the section between the saw blade and fence.

!Ripping wood that is twisted (not flat), or does not have a straight edge, or a twisted grain.

To minimize or prevent injury from kickbacks:

!Avoid conditions listed above.

!Wear a safety face shield, goggles, or glasses.

!Do not use the miter gauge and rip fence in the same operation unless provision is made by use of a facing board on the fence so as to allow the cutoff section of the workpiece to come free before the next cut is started (See Figure 31).

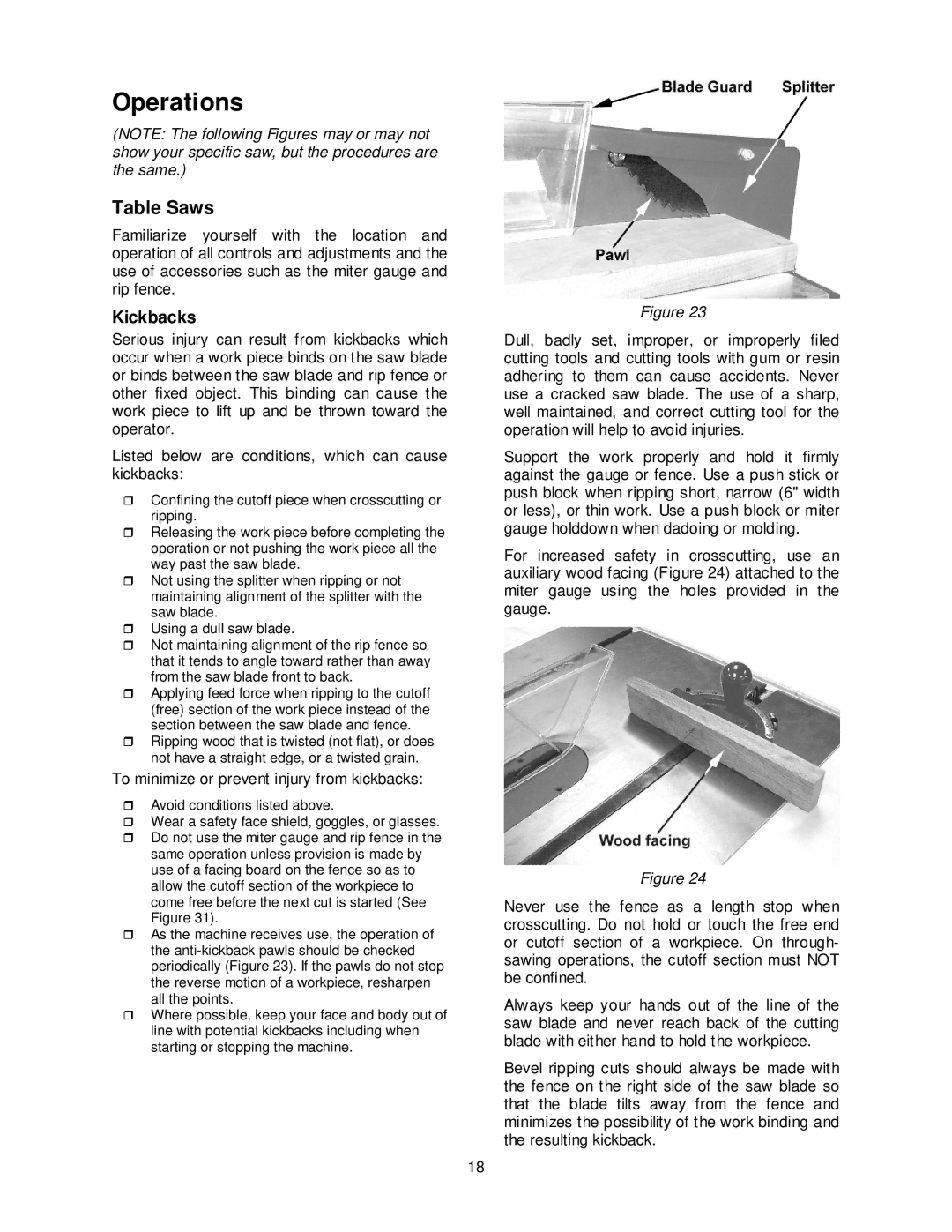

!As the machine receives use, the operation of the

!Where possible, keep your face and body out of line with potential kickbacks including when starting or stopping the machine.

Figure 23

Dull, badly set, improper, or improperly filed cutting tools and cutting tools with gum or resin adhering to them can cause accidents. Never use a cracked saw blade. The use of a sharp, well maintained, and correct cutting tool for the operation will help to avoid injuries.

Support the work properly and hold it firmly against the gauge or fence. Use a push stick or push block when ripping short, narrow (6" width or less), or thin work. Use a push block or miter gauge holddown when dadoing or molding.

For increased safety in crosscutting, use an auxiliary wood facing (Figure 24) attached to the miter gauge using the holes provided in the gauge.

Figure 24

Never use the fence as a length stop when crosscutting. Do not hold or touch the free end or cutoff section of a workpiece. On through- sawing operations, the cutoff section must NOT be confined.

Always keep your hands out of the line of the saw blade and never reach back of the cutting blade with either hand to hold the workpiece.

Bevel ripping cuts should always be made with the fence on the right side of the saw blade so that the blade tilts away from the fence and minimizes the possibility of the work binding and the resulting kickback.

18