When ripping long boards, use a support at the front of the table, such as a roller stand, and a support or "tailman" at the rear as shown in Figure 28.

Never use the rip fence beyond the point where the carriage is flush with the end of the rails.

Have the blade extend about 1/8" above the top of the workpiece. Exposing the blade above this point can be hazardous.

Resawing

Resawing is a ripping operation in which thick boards are cut into thinner ones. Narrow boards up to 3" can be resawed in one pass. Wider boards up to 6" must be resawed in two passes.

In resawing wider boards, adjust the blade height so as to overlap the two cuts by 1/2" as shown in Figure 29. Too deep a first cut can result in binding and possible kickbacks on the second cut. Always use the same side of the board against the fence for both cuts.

Figure 29

Crosscutting

Crosscutting is where the workpiece is fed cross grain into the saw blade using the miter gauge to support and position the workpiece (Figure 30).

Figure 30

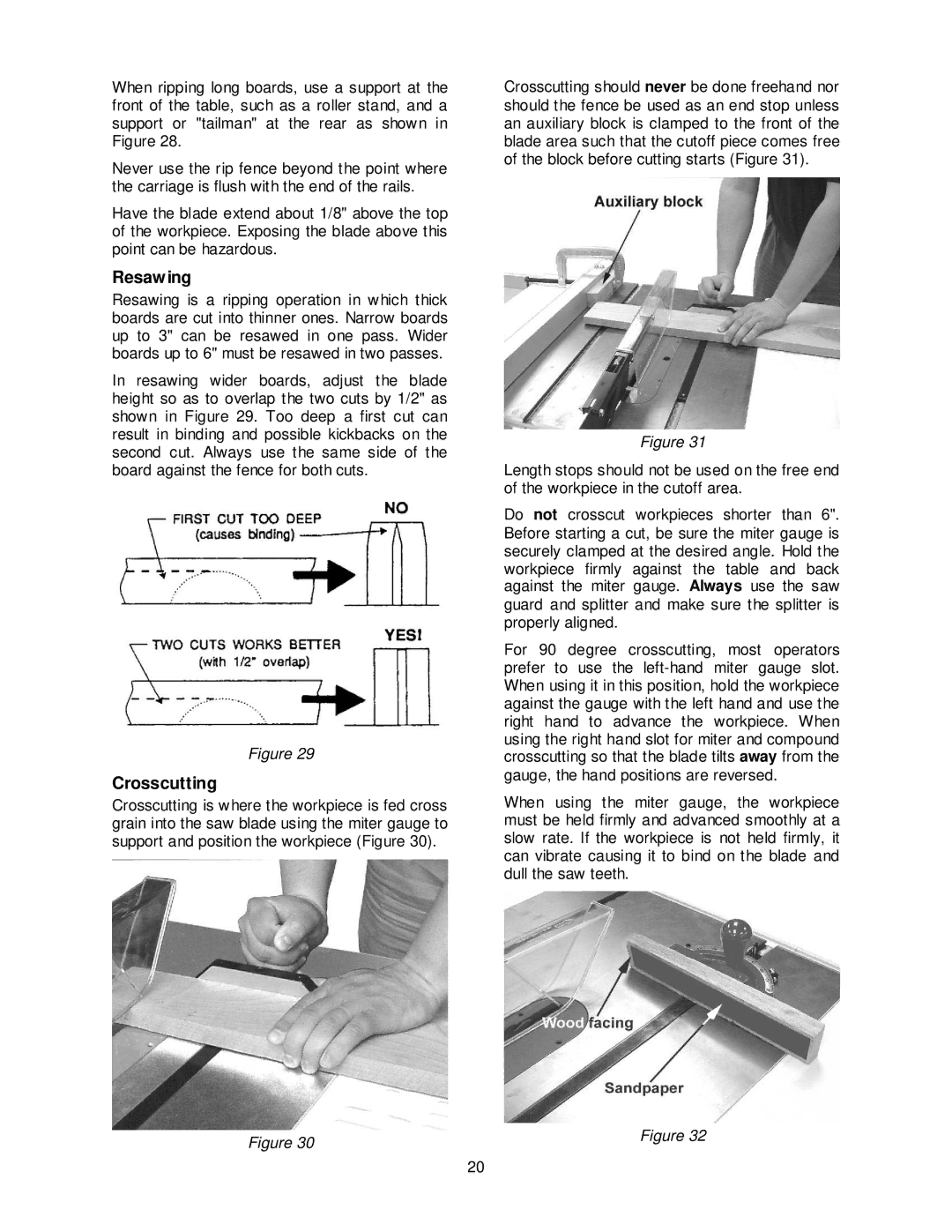

Crosscutting should never be done freehand nor should the fence be used as an end stop unless an auxiliary block is clamped to the front of the blade area such that the cutoff piece comes free of the block before cutting starts (Figure 31).

Figure 31

Length stops should not be used on the free end of the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6". Before starting a cut, be sure the miter gauge is securely clamped at the desired angle. Hold the workpiece firmly against the table and back against the miter gauge. Always use the saw guard and splitter and make sure the splitter is properly aligned.

For 90 degree crosscutting, most operators prefer to use the

When using the miter gauge, the workpiece must be held firmly and advanced smoothly at a slow rate. If the workpiece is not held firmly, it can vibrate causing it to bind on the blade and dull the saw teeth.

Figure 32

20