To improve the effectiveness of the miter gauge in crosscutting, some users mount an auxiliary wooden extension face (with a

Provide auxiliary support for any workpiece extending beyond the table top with a tendency to sag and lift up off the table.

Stop rods can be used in the holes provided in the miter gauge for repetitive work of equal length. Do not use a stop rod on the free end of a workpiece. It should be used on the side of the miter gauge opposite the saw blade.

Have the blade extend about 1/8" above the top of the workpiece. Exposing the blade above this point can be hazardous.

Bevel and Miter Operations

Bevel Cut – A bevel cut is a special type of operation where the saw blade is tilted at an angle less than 90 degrees to the table top (Figure 33). Operations are performed in the same manner as ripping or crosscutting except the fence or miter gauge should be used on the

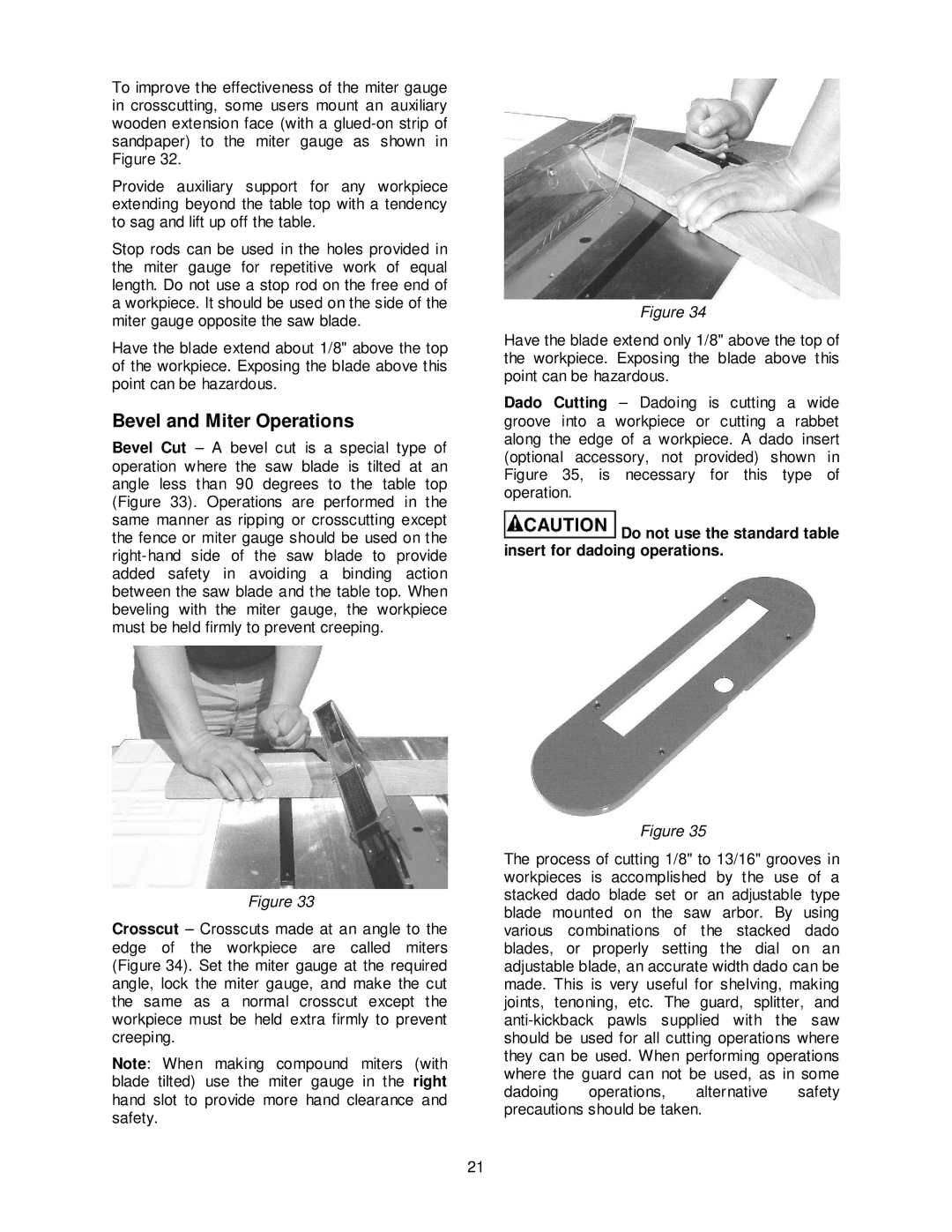

Figure 34

Have the blade extend only 1/8" above the top of the workpiece. Exposing the blade above this point can be hazardous.

Dado Cutting – Dadoing is cutting a wide groove into a workpiece or cutting a rabbet along the edge of a workpiece. A dado insert (optional accessory, not provided) shown in Figure 35, is necessary for this type of operation.

Do not use the standard table insert for dadoing operations.

Do not use the standard table insert for dadoing operations.

Figure 33

Crosscut – Crosscuts made at an angle to the edge of the workpiece are called miters (Figure 34). Set the miter gauge at the required angle, lock the miter gauge, and make the cut the same as a normal crosscut except the workpiece must be held extra firmly to prevent creeping.

Note: When making compound miters (with blade tilted) use the miter gauge in the right hand slot to provide more hand clearance and safety.

Figure 35

The process of cutting 1/8" to 13/16" grooves in workpieces is accomplished by the use of a stacked dado blade set or an adjustable type blade mounted on the saw arbor. By using various combinations of the stacked dado blades, or properly setting the dial on an adjustable blade, an accurate width dado can be made. This is very useful for shelving, making joints, tenoning, etc. The guard, splitter, and

21