DAILY INSPECTION

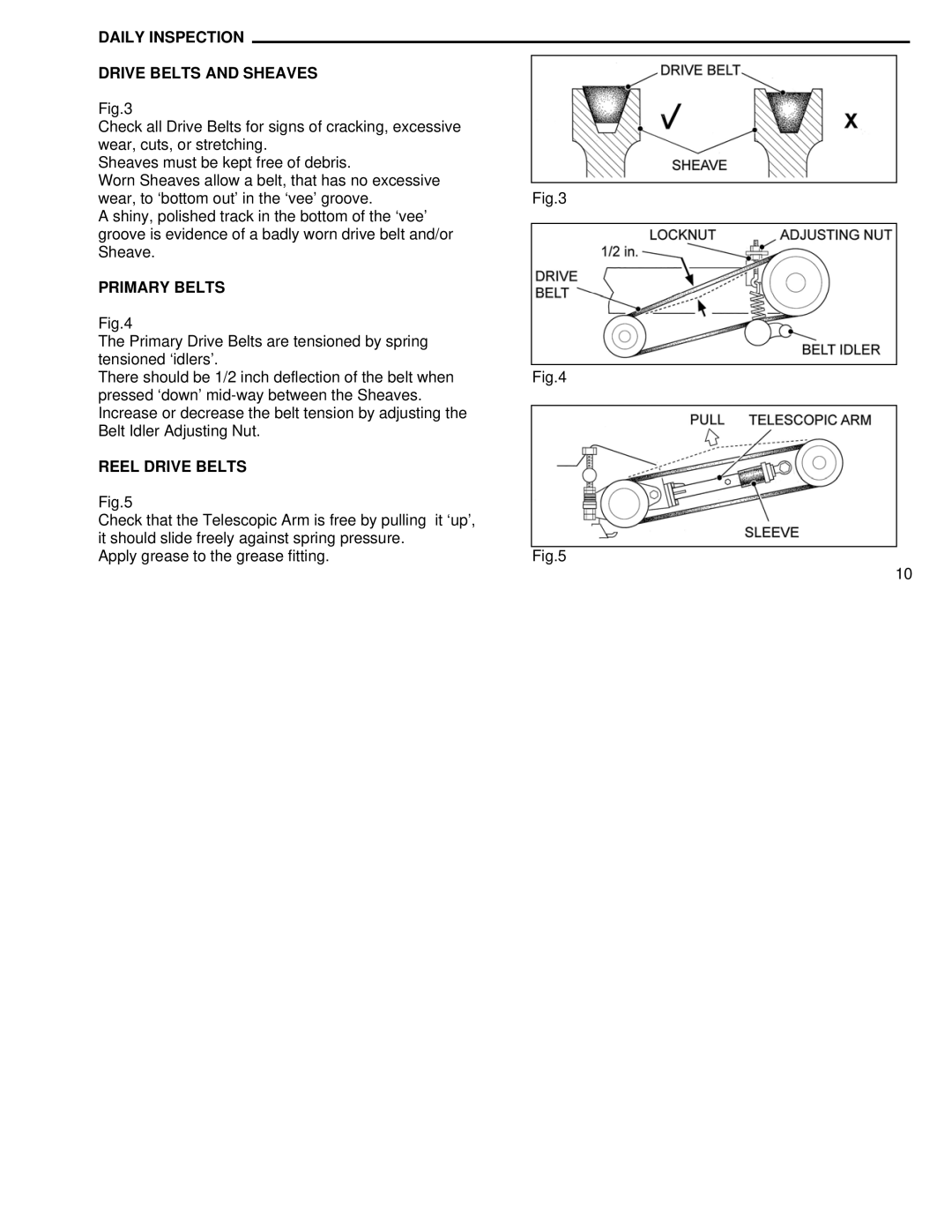

DRIVE BELTS AND SHEAVES

Fig.3

Check all Drive Belts for signs of cracking, excessive wear, cuts, or stretching.

Sheaves must be kept free of debris.

Worn Sheaves allow a belt, that has no excessive wear, to ‘bottom out’ in the ‘vee’ groove.

A shiny, polished track in the bottom of the ‘vee’ groove is evidence of a badly worn drive belt and/or Sheave.

PRIMARY BELTS

Fig.4

The Primary Drive Belts are tensioned by spring tensioned ‘idlers’.

There should be 1/2 inch deflection of the belt when pressed ‘down’

REEL DRIVE BELTS

Fig.5

Check that the Telescopic Arm is free by pulling it ‘up’, it should slide freely against spring pressure.

Apply grease to the grease fitting.

Fig.3

Fig.4

Fig.5

10