Table of Contents

Section 1: Assembly and Set-up

Before attempting to assemble the seeder use the following as a check list. Having all the needed parts and equipment readily at hand will speed up your assembly task and will make the job as safe as possible.

Pre-Assembly Checklist

|

|

| Check | Reference |

|

|

| Fasteners and pins that were | Operator’s |

|

|

| ||

|

|

| shipped with the seeder. | Manual |

|

|

| NOTE: All hardware from the |

|

|

|

| factory has been installed in the |

|

|

|

| location where it will be used. If a |

|

|

|

| part or fastener is temporarily |

|

|

|

| removed for assembly reasons, |

|

|

|

| remember where it goes. Keep the |

|

|

|

| parts separated. |

|

|

|

|

|

|

|

|

| All working parts are moving | Operator’s |

|

|

| ||

|

|

| freely, bolts are tight and cotter | Manual |

|

|

| ||

|

|

| pins are spread. |

|

|

|

|

|

|

|

|

| All grease fittings are in place and | Section 5 |

|

|

| ||

|

|

| lubricated. | Page 39 |

|

|

| ||

|

|

|

|

|

|

|

| Proper tension and alignment on | Operator’s |

|

|

| ||

|

|

| all drive chains. | Manual |

|

|

| ||

|

|

|

|

|

|

|

| Safety decals are correctly located | Important |

|

|

| and legible. Replace if damaged. | Safety |

|

|

| ||

|

|

|

| Information |

|

|

| Red and amber reflectors are | Important |

|

|

| ||

|

|

| correctly located and visible. | Safety |

|

|

| ||

|

|

|

| Information |

|

|

|

|

|

|

|

| “Slow moving vehicle” emblem is | Important |

|

|

| ||

|

|

| in place. | Safety |

|

|

| ||

|

|

|

| Information |

|

|

|

|

|

|

|

| Inflate tires to specified PSI air | Section 8 |

|

|

| ||

|

|

| pressure. Tighten wheel bolts to | Page 48 |

|

|

| ||

|

|

| specified torque. |

|

|

|

|

|

|

|

|

| Have a minimum of 2 people at | Section 1 |

|

|

| ||

|

|

| hand while assembling the drill. |

|

|

|

|

| |

|

|

|

|

|

|

|

| Have a fork lift or loader along with | Section 1 |

|

|

| ||

|

|

| chains and safety stands that are |

|

|

|

|

| |

|

|

| sized for the job ready for the |

|

|

|

| assembly task. |

|

|

|

|

|

|

|

|

| Have a tractor with remote | Section 1 |

|

|

| ||

|

|

| hydraulics ready to attach to the | Page 15 |

|

|

| ||

|

|

| tongue. The tongue must be |

|

|

|

| anchored to a large enough tractor |

|

|

|

| to overcome the negative tongue |

|

|

|

| weight that will be present if the |

|

|

|

| unit is equipped with front wheels. |

|

|

|

| CAUTION! Be familiar with the |

|

|

|

| term NEGATIVE TONGUE |

|

|

|

| WEIGHT. Be aware of the special |

|

|

|

| precautions you should take when |

|

|

|

| working with an implement that |

|

|

|

| can develop Negative Tongue |

|

|

|

| Weight. |

|

|

|

|

|

|

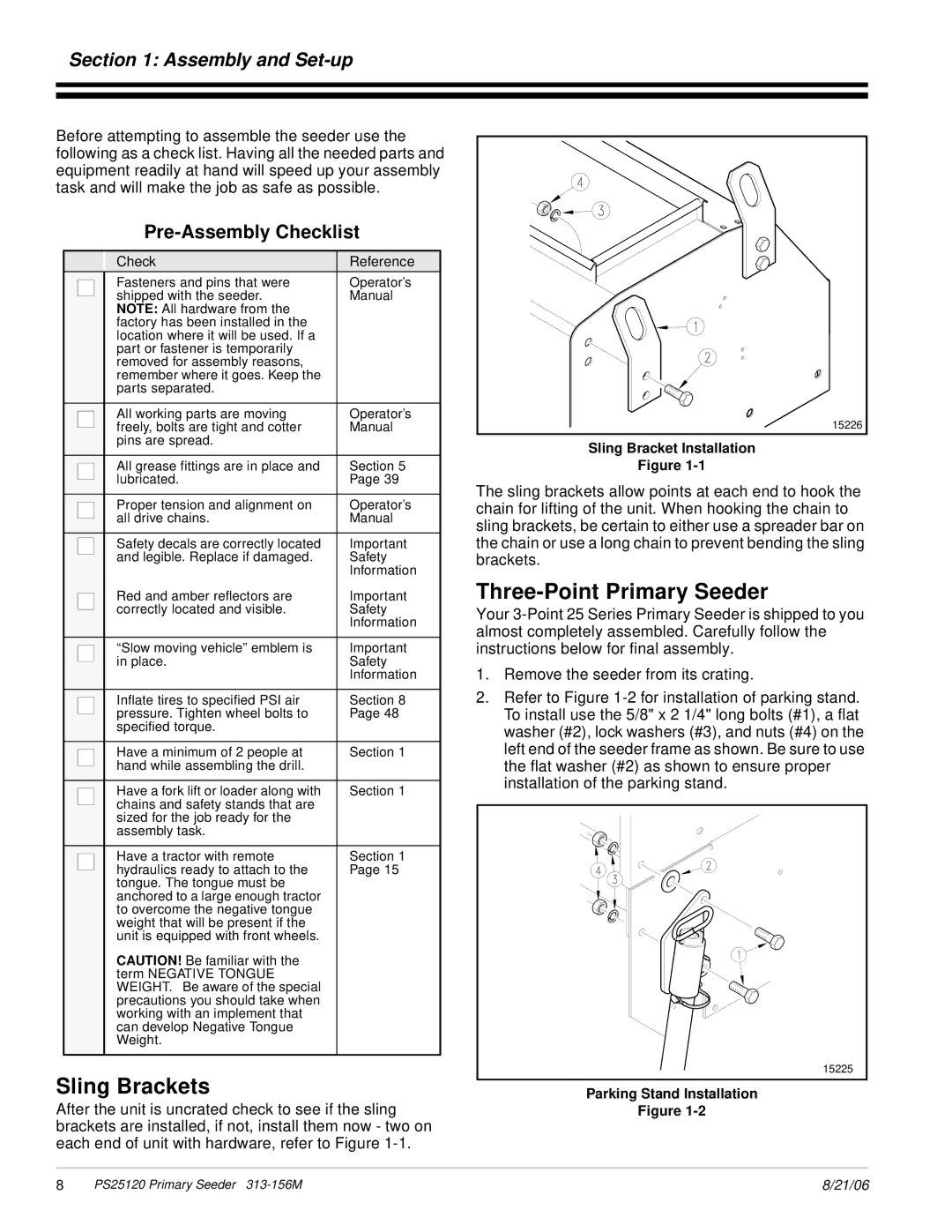

Sling Brackets

After the unit is uncrated check to see if the sling brackets are installed, if not, install them now - two on each end of unit with hardware, refer to Figure

15226 |

Sling Bracket Installation

Figure

The sling brackets allow points at each end to hook the chain for lifting of the unit. When hooking the chain to sling brackets, be certain to either use a spreader bar on the chain or use a long chain to prevent bending the sling brackets.

Three-Point Primary Seeder

Your

1.Remove the seeder from its crating.

2.Refer to Figure

15225 |

Parking Stand Installation

Figure

8 | PS25120 Primary Seeder | 8/21/06 |