Table of Contents

Section 4: Operating Instructions

Operating Check List

Hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training involved in the operation, transport, maintenance and storage of the Rotary Cutter. Therefore, it is absolutely essential that no one operates the Rotary Cutter without first having read, fully understood and become totally familiar with the Operator’s Manual. Make sure the operator has paid particular attention to:

•Important Safety Information, pages 1 to 6

•Section 1: Assembly and

•Section 3: Adjustments, page 14

•Section 4: Operating Instructions, page 16

•Section 5: Maintenance and Lubrication, page 19

The following inspection should be performed before using the cutter.

IMPORTANT: Stop PTO immediately if vibration continues after a few revolutions during

IMPORTANT: Do not exceed rated cutter PTO speed. Excessive engine speed will cause damage to the power train components.

7.Start tractor, set throttle to idle or slightly above idle and slowly engage PTO. Initial

8.Once the cutter is running smoothly, increase tractor PTO speed to 540 RPM. Stop PTO rotation immediately if vibration occurs.

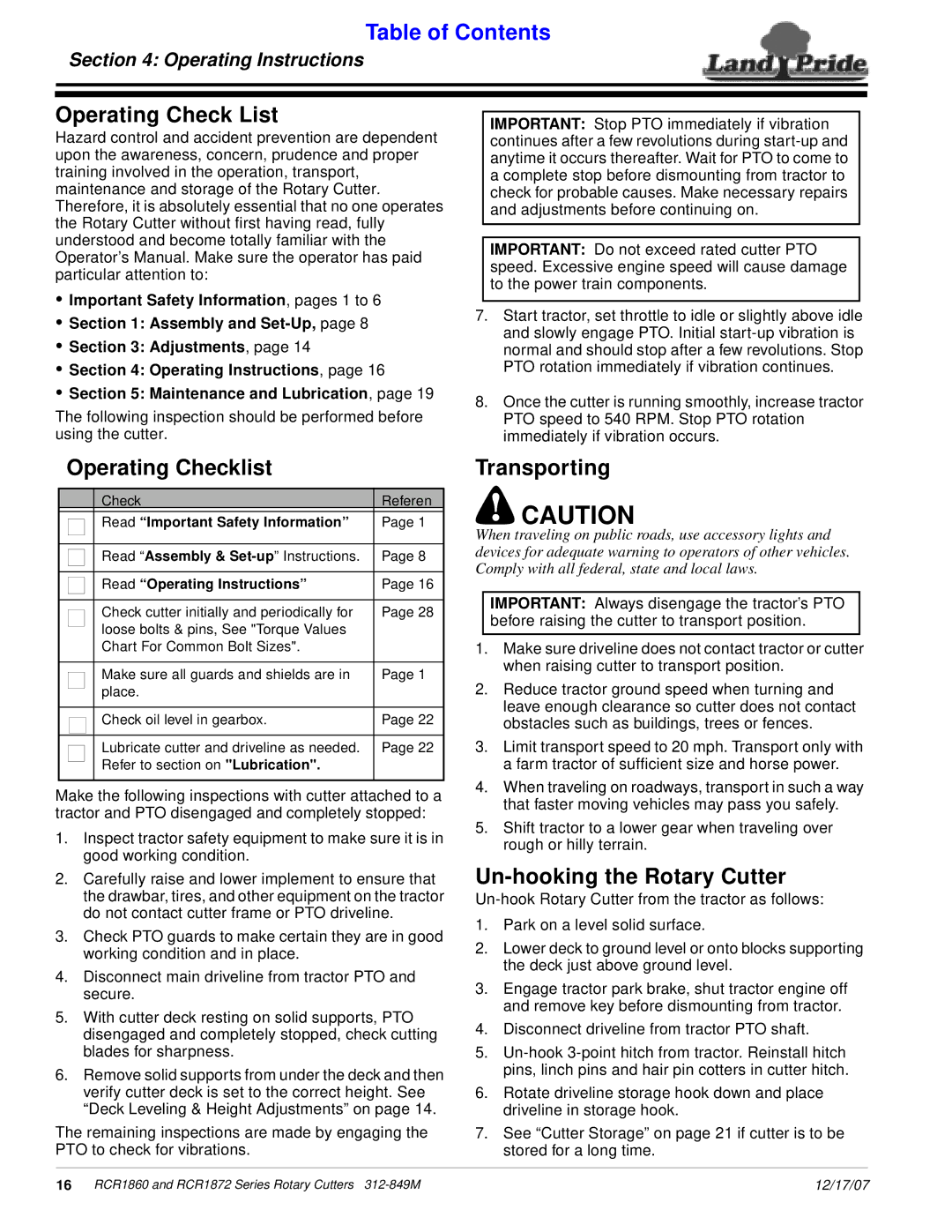

Operating Checklist

| Check | Referen |

|

|

|

| Read “Important Safety Information” | Page 1 |

|

|

|

| Read “Assembly & | Page 8 |

|

|

|

| Read “Operating Instructions” | Page 16 |

|

|

|

| Check cutter initially and periodically for | Page 28 |

| loose bolts & pins, See "Torque Values |

|

| Chart For Common Bolt Sizes". |

|

|

|

|

| Make sure all guards and shields are in | Page 1 |

| place. |

|

|

|

|

| Check oil level in gearbox. | Page 22 |

|

|

|

| Lubricate cutter and driveline as needed. | Page 22 |

| Refer to section on "Lubrication". |

|

|

|

|

Make the following inspections with cutter attached to a tractor and PTO disengaged and completely stopped:

1.Inspect tractor safety equipment to make sure it is in good working condition.

2.Carefully raise and lower implement to ensure that the drawbar, tires, and other equipment on the tractor do not contact cutter frame or PTO driveline.

3.Check PTO guards to make certain they are in good working condition and in place.

4.Disconnect main driveline from tractor PTO and secure.

5.With cutter deck resting on solid supports, PTO disengaged and completely stopped, check cutting blades for sharpness.

6.Remove solid supports from under the deck and then verify cutter deck is set to the correct height. See “Deck Leveling & Height Adjustments” on page 14.

The remaining inspections are made by engaging the PTO to check for vibrations.

Transporting

!CAUTION

When traveling on public roads, use accessory lights and devices for adequate warning to operators of other vehicles. Comply with all federal, state and local laws.

IMPORTANT: Always disengage the tractor’s PTO before raising the cutter to transport position.

1.Make sure driveline does not contact tractor or cutter when raising cutter to transport position.

2.Reduce tractor ground speed when turning and leave enough clearance so cutter does not contact obstacles such as buildings, trees or fences.

3.Limit transport speed to 20 mph. Transport only with a farm tractor of sufficient size and horse power.

4.When traveling on roadways, transport in such a way that faster moving vehicles may pass you safely.

5.Shift tractor to a lower gear when traveling over rough or hilly terrain.

Un-hooking the Rotary Cutter

1.Park on a level solid surface.

2.Lower deck to ground level or onto blocks supporting the deck just above ground level.

3.Engage tractor park brake, shut tractor engine off and remove key before dismounting from tractor.

4.Disconnect driveline from tractor PTO shaft.

5.

6.Rotate driveline storage hook down and place driveline in storage hook.

7.See “Cutter Storage” on page 21 if cutter is to be stored for a long time.

16 RCR1860 and RCR1872 Series Rotary Cutters | 12/17/07 |