Land Pride | Table of Contents |

Section 5: Maintenance and Lubrication

Maintenance

Proper servicing and adjustment is the key to the long life of any farm implement. Careful and systematic inspection can avoid costly down time, maintenance and repairs.

After using your cutter for several hours, check all bolts to be sure they are tight.

Replace any worn, damaged or illegible safety labels by obtaining new labels from your Land Pride Dealer.

Service Cutter Blades

balance. The following precautions should be taken when sharpening blades:

a.Do not remove more material than necessary.

b.Do not heat and pound out a cutting edge.

c.Do not grind blades to a razor edge. Leave a blunt cutting edge approximately 1/16” thick.

d.Always grind cutting edge so end of blade remains square to cutting edge and not rounded.

e.Do not sharpen back side of blade.

f.Both blades should weigh the same after sharpening with not more than 1 1/2 oz. difference.

!DANGER

Always disconnect main driveline from tractor PTO before servicing underside of cutter deck. Cutter can be engaged if tractor is started resulting in damage to the cutter, bodily injury or death.

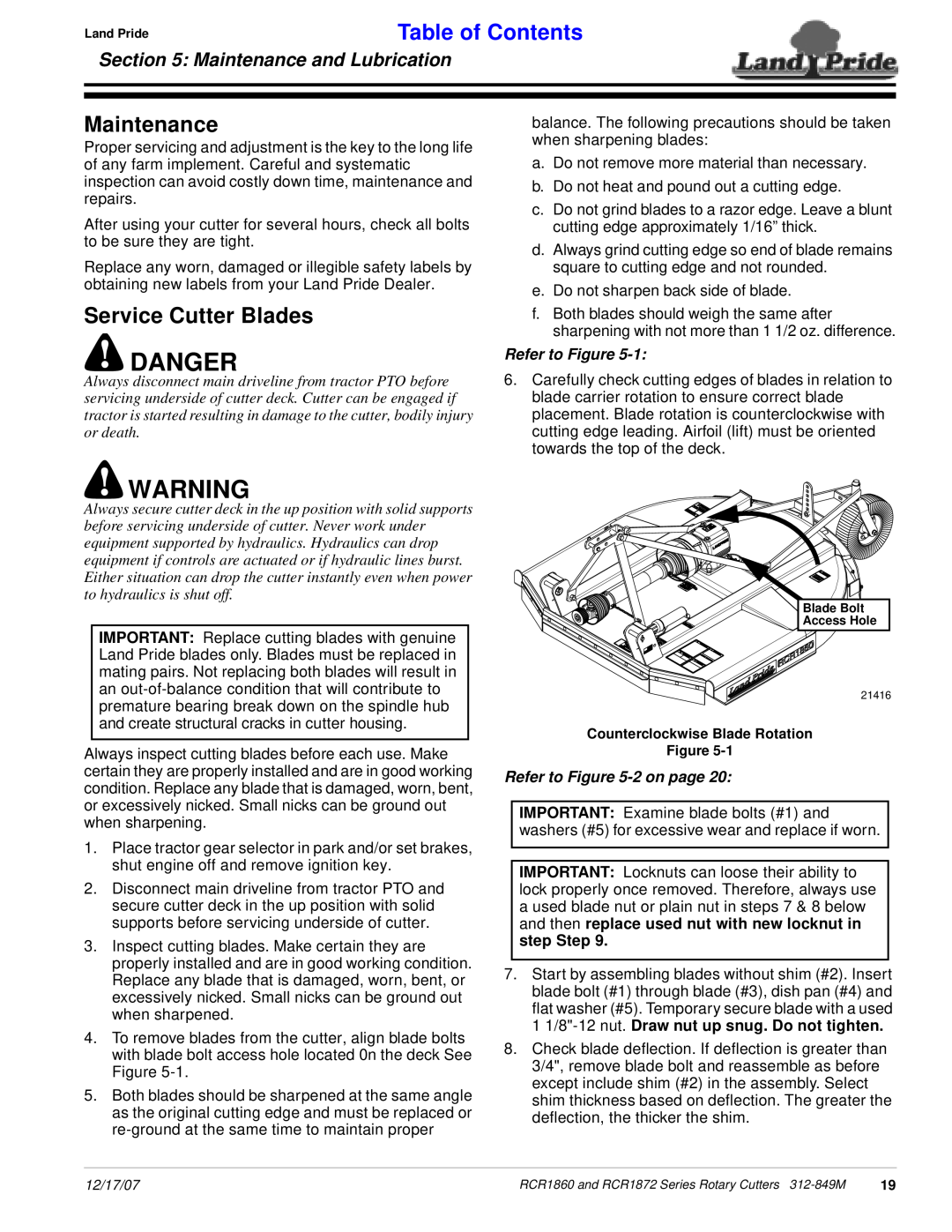

Refer to Figure

6.Carefully check cutting edges of blades in relation to blade carrier rotation to ensure correct blade placement. Blade rotation is counterclockwise with cutting edge leading. Airfoil (lift) must be oriented towards the top of the deck.

!WARNING

Always secure cutter deck in the up position with solid supports before servicing underside of cutter. Never work under equipment supported by hydraulics. Hydraulics can drop equipment if controls are actuated or if hydraulic lines burst. Either situation can drop the cutter instantly even when power to hydraulics is shut off.

IMPORTANT: Replace cutting blades with genuine Land Pride blades only. Blades must be replaced in mating pairs. Not replacing both blades will result in an

Always inspect cutting blades before each use. Make certain they are properly installed and are in good working condition. Replace any blade that is damaged, worn, bent, or excessively nicked. Small nicks can be ground out when sharpening.

1.Place tractor gear selector in park and/or set brakes, shut engine off and remove ignition key.

2.Disconnect main driveline from tractor PTO and secure cutter deck in the up position with solid supports before servicing underside of cutter.

3.Inspect cutting blades. Make certain they are properly installed and are in good working condition. Replace any blade that is damaged, worn, bent, or excessively nicked. Small nicks can be ground out when sharpened.

4.To remove blades from the cutter, align blade bolts with blade bolt access hole located 0n the deck See Figure

5.Both blades should be sharpened at the same angle as the original cutting edge and must be replaced or

Blade Bolt

Access Hole

21416

Counterclockwise Blade Rotation

Figure

Refer to Figure 5-2 on page 20:

IMPORTANT: Examine blade bolts (#1) and washers (#5) for excessive wear and replace if worn.

IMPORTANT: Locknuts can loose their ability to lock properly once removed. Therefore, always use a used blade nut or plain nut in steps 7 & 8 below and then replace used nut with new locknut in step Step 9.

7.Start by assembling blades without shim (#2). Insert blade bolt (#1) through blade (#3), dish pan (#4) and flat washer (#5). Temporary secure blade with a used 1

8.Check blade deflection. If deflection is greater than 3/4", remove blade bolt and reassemble as before except include shim (#2) in the assembly. Select shim thickness based on deflection. The greater the deflection, the thicker the shim.

12/17/07 | RCR1860 and RCR1872 Series Rotary Cutters | 19 |