Land Pride | Table of Contents |

Section 5: Maintenance and Lubrication

5.Tighten each of the 8 spring retainer nuts on the clutch housing exactly 2 revolutions to restore clutch to original setting pressure.

6.The clutch should be checked during the first hour of cutting and periodically each week. An additional set of scribe marks can be added to check for slippage. See Figure

Clutch Assembly and Disassembly

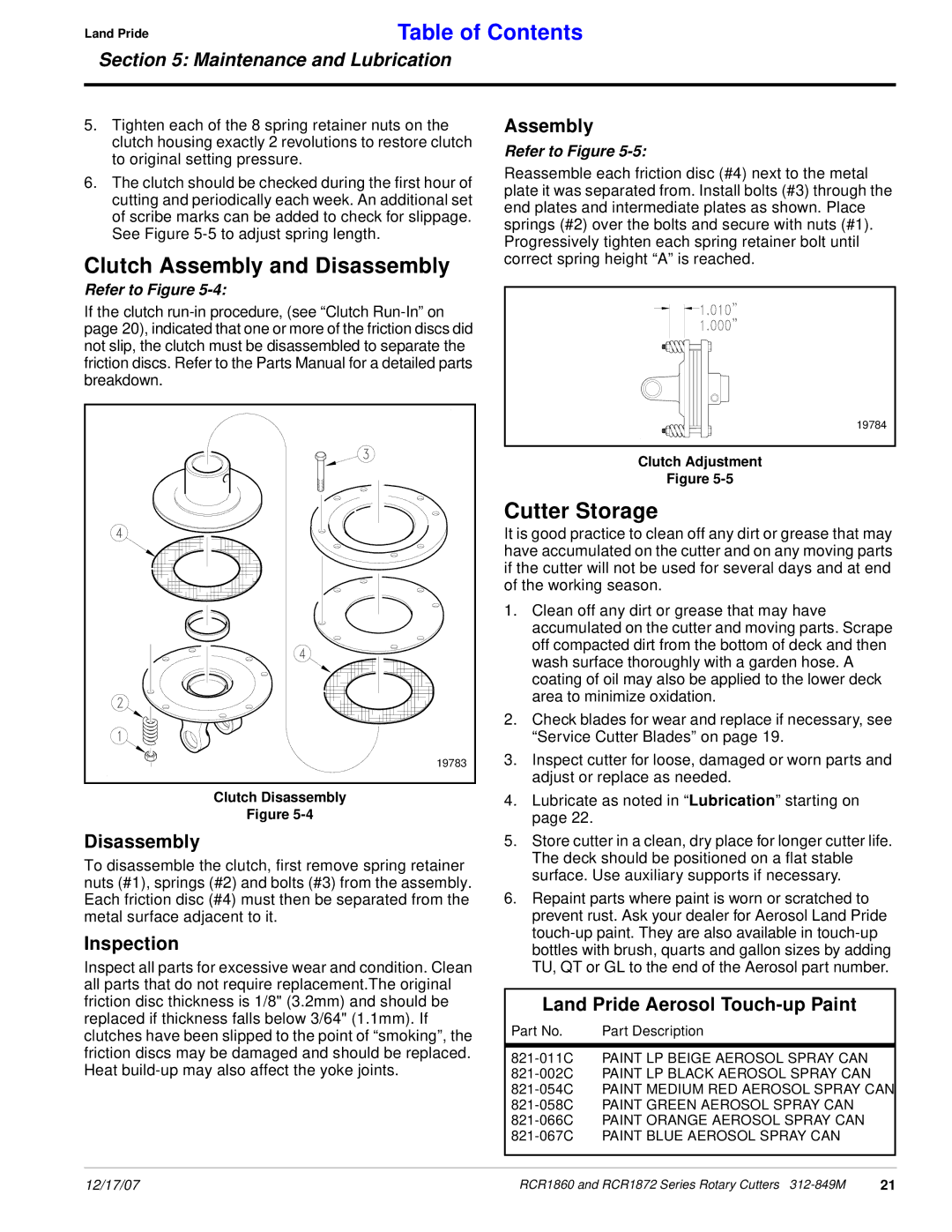

Refer to Figure 5-4:

If the clutch

19783 |

Clutch Disassembly

Figure

Disassembly

To disassemble the clutch, first remove spring retainer nuts (#1), springs (#2) and bolts (#3) from the assembly. Each friction disc (#4) must then be separated from the metal surface adjacent to it.

Inspection

Inspect all parts for excessive wear and condition. Clean all parts that do not require replacement.The original friction disc thickness is 1/8" (3.2mm) and should be replaced if thickness falls below 3/64" (1.1mm). If clutches have been slipped to the point of “smoking”, the friction discs may be damaged and should be replaced. Heat

Assembly

Refer to Figure 5-5:

Reassemble each friction disc (#4) next to the metal plate it was separated from. Install bolts (#3) through the end plates and intermediate plates as shown. Place springs (#2) over the bolts and secure with nuts (#1). Progressively tighten each spring retainer bolt until correct spring height “A” is reached.

19784

Clutch Adjustment

Figure

Cutter Storage

It is good practice to clean off any dirt or grease that may have accumulated on the cutter and on any moving parts if the cutter will not be used for several days and at end of the working season.

1.Clean off any dirt or grease that may have accumulated on the cutter and moving parts. Scrape off compacted dirt from the bottom of deck and then wash surface thoroughly with a garden hose. A coating of oil may also be applied to the lower deck area to minimize oxidation.

2.Check blades for wear and replace if necessary, see “Service Cutter Blades” on page 19.

3.Inspect cutter for loose, damaged or worn parts and adjust or replace as needed.

4.Lubricate as noted in “Lubrication” starting on page 22.

5.Store cutter in a clean, dry place for longer cutter life. The deck should be positioned on a flat stable surface. Use auxiliary supports if necessary.

6.Repaint parts where paint is worn or scratched to prevent rust. Ask your dealer for Aerosol Land Pride

Land Pride Aerosol Touch-up Paint

Part No. | Part Description |

12/17/07 | RCR1860 and RCR1872 Series Rotary Cutters | 21 |