VERTICAL VENT FIGURES/TABLES

(continued)

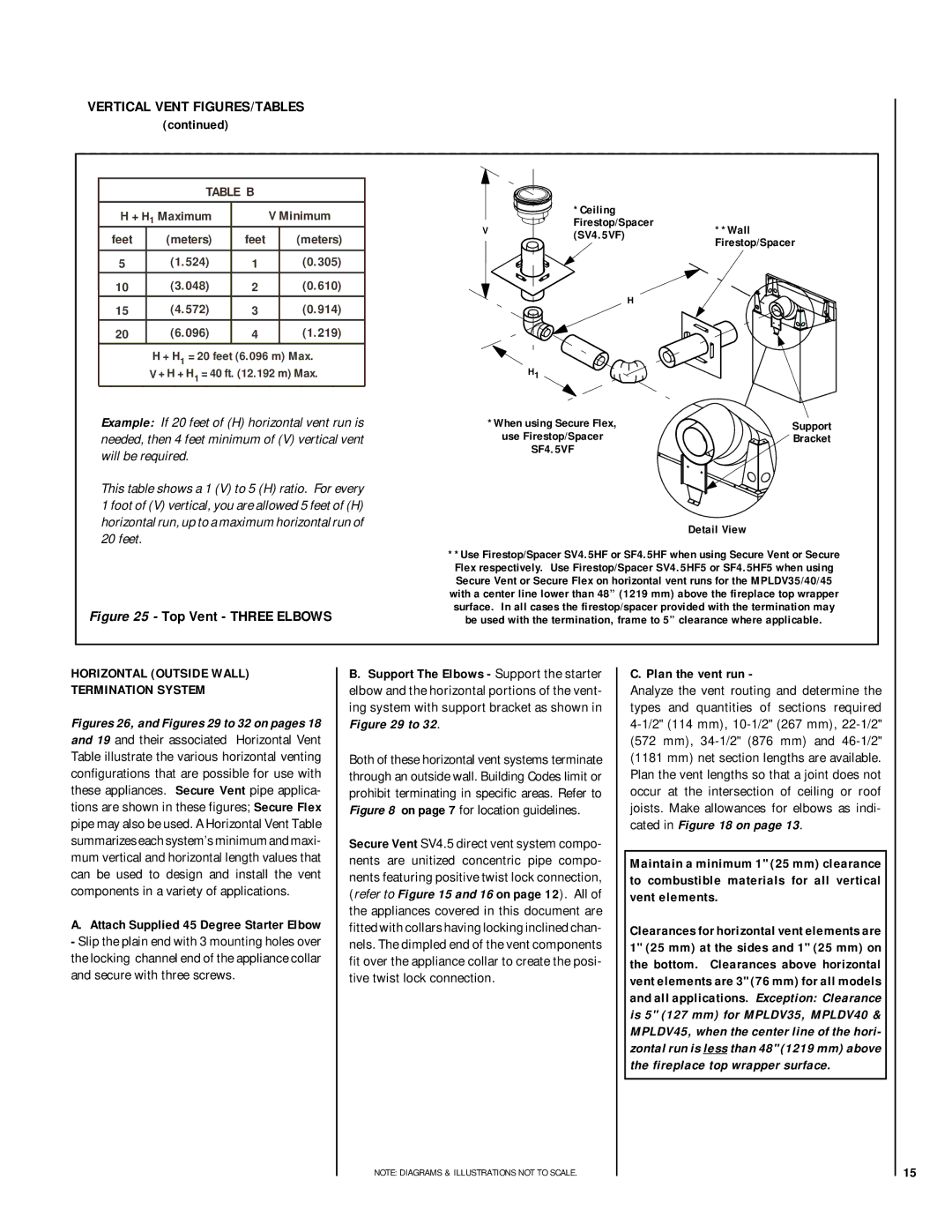

TABLE B

H + H1 Maximum |

| V Minimum | ||

feet | (meters) | feet |

| (meters) |

|

|

|

|

|

5 | (1.524) | 1 |

| (0.305) |

10 | (3.048) | 2 |

| (0.610) |

15 | (4.572) | 3 |

| (0.914) |

20 | (6.096) | 4 |

| (1.219) |

| H + H1 = 20 feet (6.096 m) Max. | |||

| V + H + H1 = 40 ft. (12.192 m) Max. | |||

Example: If 20 feet of (H) horizontal vent run is needed, then 4 feet minimum of (V) vertical vent will be required.

| *Ceiling |

V | Firestop/Spacer |

(SV4.5VF) |

H

H1

*When using Secure Flex, use Firestop/Spacer SF4.5VF

**Wall

Firestop/Spacer

Support

Bracket

This table shows a 1 (V) to 5 (H) ratio. For every 1 foot of (V) vertical, you are allowed 5 feet of (H) horizontal run, up to a maximum horizontal run of 20 feet.

Figure 25 - Top Vent - THREE ELBOWS

Detail View

**Use Firestop/Spacer SV4.5HF or SF4.5HF when using Secure Vent or Secure Flex respectively. Use Firestop/Spacer SV4.5HF5 or SF4.5HF5 when using Secure Vent or Secure Flex on horizontal vent runs for the MPLDV35/40/45 with a center line lower than 48” (1219 mm) above the fireplace top wrapper surface. In all cases the firestop/spacer provided with the termination may be used with the termination, frame to 5” clearance where applicable.

HORIZONTAL (OUTSIDE WALL)

TERMINATION SYSTEM

Figures 26, and Figures 29 to 32 on pages 18 and 19 and their associated Horizontal Vent Table illustrate the various horizontal venting configurations that are possible for use with these appliances. Secure Vent pipe applica- tions are shown in these figures; Secure Flex pipe may also be used. A Horizontal Vent Table summarizes each system’s minimum and maxi- mum vertical and horizontal length values that can be used to design and install the vent components in a variety of applications.

A.Attach Supplied 45 Degree Starter Elbow - Slip the plain end with 3 mounting holes over the locking channel end of the appliance collar and secure with three screws.

B.Support The Elbows - Support the starter elbow and the horizontal portions of the vent- ing system with support bracket as shown in Figure 29 to 32.

Both of these horizontal vent systems terminate through an outside wall. Building Codes limit or prohibit terminating in specific areas. Refer to Figure 8 on page 7 for location guidelines.

Secure Vent SV4.5 direct vent system compo- nents are unitized concentric pipe compo- nents featuring positive twist lock connection, (refer to Figure 15 and 16 on page 12). All of the appliances covered in this document are fitted with collars having locking inclined chan- nels. The dimpled end of the vent components fit over the appliance collar to create the posi- tive twist lock connection.

C. Plan the vent run -

Analyze the vent routing and determine the types and quantities of sections required

Maintain a minimum 1" (25 mm) clearance to combustible materials for all vertical vent elements.

Clearances for horizontal vent elements are 1" (25 mm) at the sides and 1" (25 mm) on the bottom. Clearances above horizontal vent elements are 3" (76 mm) for all models and all applications. Exception: Clearance is 5" (127 mm) for MPLDV35, MPLDV40 & MPLDV45, when the center line of the hori- zontal run is less than 48" (1219 mm) above the fireplace top wrapper surface.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

15